15

Adjusting the CO

2

Regulator

? The gauge monitors low internal keg pressure and should be

adjusted to read 10-12 PSI. (See Figure 10)

? In order to do that:

1. Release adjustment lock nut marked 2.

2. Using a flat screwdriver, turn regulator screw marked 3. If

increased low pressure is sought, rotate screw clockwise. By

rotating it counter clockwise, low pressure will be decreased.

When the required operati ng pressure is attained, retighten

lock nut 2.

3. Open secondary shut off valve to let CO

2

flow into the keg.

Figure 10

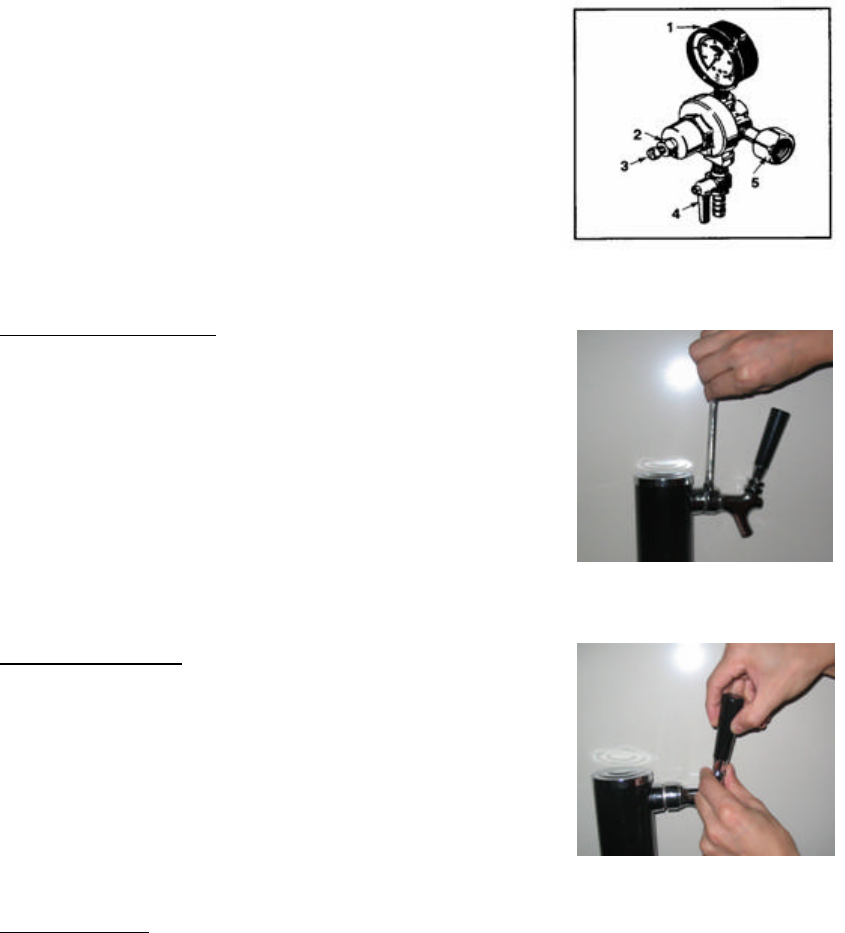

? Spanner Faucet Wrench

? Spanner faucet wrench provided for either removing or tightening

connection. (See Figure 11)

Figure 11

? Plastic Faucet Lever

? Attach the black plastic lever (pull handle) provided on the top of

the faucet tightening it by hand clockwise until the end, holding in

the silver snug underneath so it does not move.

? If there is still a small drip from the faucet, you may have tightened

the plastic lever too much and may need to unscrew silver snug

counter-clockwise (as shown in Figure 12) one turn. That should

correct the problem if exists.

Figure 12

? Dispensing Beer

? Keep beer keg refrigerated at all times.

? Never allow beer lines to dry out.

? Use clean beer glassware before pouring.

? Hold glass at a 45° angle when 2/3 full, start to straighten glass and tap it off.

? Always make sure the faucet handle is pushed all the way back.

NOTE: Keg sizes that can be used in your beer dispenser.

1/2 barrel 59 Liters 15.5 gals. 1984 oz. 164 / 12-oz. Glass

1/4 barrel 30 Liters 7.8 gals. 992 oz. 82 / 12-oz. Glass

1/6 barrel 20 Liters 5.2 gals. 661 oz. 55 / 12-oz. Glass

1/8 barrel 15 Liters 4.0 gals. 496 oz. 41 / 12-oz. Glass

NOTE: Our Beer dispenser accepts almost all Brand Name ½ kegs. However Coors’ kegs do not fit in

our unit.