9

10004894

LHEDV Series Direct Vent Insert

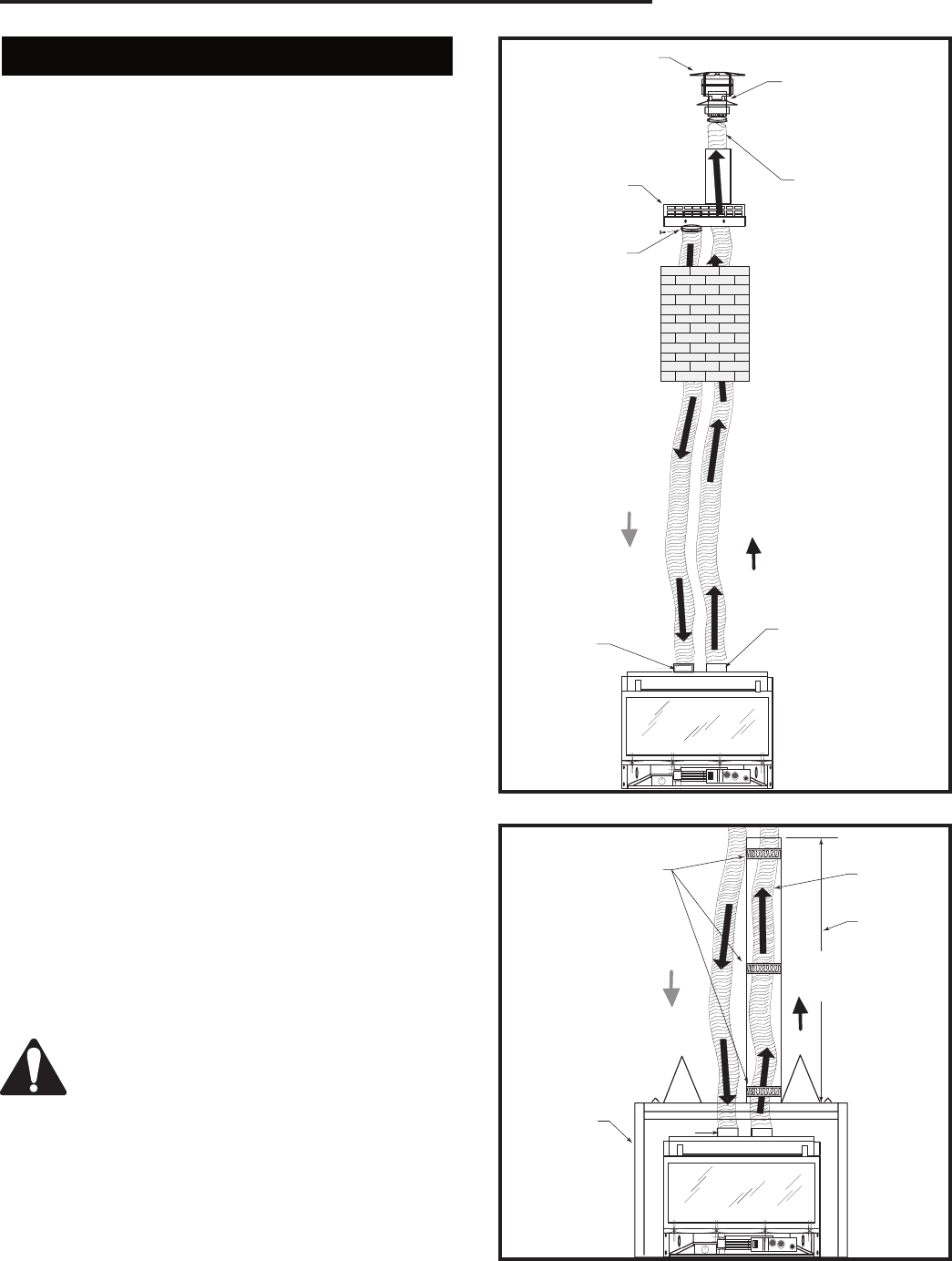

Liner Installation

The collar extending down from the termination base

is the air intake connector. Be sure the flex vent, which

is connected to this collar, is also connected to the

labelled air intake flue collar on the fireplace. Make sure

the flex vent is attached on the correct collar and cap

for exhaust as well.

Slide the insulation provided in the termination kit over

the two (2) 3" flex liners, (to be attached to the 3" flue

collar and cap of the termination). Feed one 3" flex

vent from the bottom of the termination up through the

4" sleeve. Apply hi-temp sealant on the rain cap col-

lar and slide the flex vent over the end of the rain cap

collar fastening with the clamp provided. Slide the flex

liner back down the 4" sleeve until 4" cap slides over

the sleeve. Attach cap to the sleeve with four (4) screws

supplied. Apply hi-temp sealant over the air intake

collar and attach intake flex vent in the same method.

Feed the two flex liners down the chimney through the

damper opening. Tighten termination to the chimney

using the screws provided. (Fig. 10) NOTE: For Round

Vent Terminations - tighten termination to the chimney

by pushing the four (4) straps of the vent termination

against the chimney and secure with four (4) screws

provided. (Fig. 12)

In case the fireplace opening is only minimum height

21" (533 mm) and access from the front is not possible,

follow the instructions below.

1. Remove flue collar plate assembly. Unbolt the top

fastener plate and move it to the back first before

sliding the flue collar plate out from the top of the

unit. (Fig. 13)

2. Apply a bead of hi-temp sealant on the end of the

collar before attaching the liner to the flue collar.

Fasten it with two clamps then adjust fastener plate

all the way to the back before sliding flue gas plate

back onto the unit. (Figs. 14 and 15)

3. After the flue collar plate is set on the cabinet top,

make sure the front edge of the flue collar plate is

completely in contact with the back edge of the cabi-

net top. (Fig. 16)

4. Put the machine screw back into the fastener plate.

Bolt the plate until it is locked. (Fig. 17)

Under no circumstances should insulation

be put between the damper and the top of

the unit. This may cause condensation and

overheating of the unit.

FP1280

RHEDV

vent termination

1/03

Flue gas exits

through the

vent termination

rain cap

1) Attach flexible pipe

to rain cap

2) Secure with clamp

3) Attach raincap to

vent termiantion us-

ing three screws

Pull flexible pipe

through vent

termination

Outside combustion

air enters through the

lower level of the vent

termination

Secure with

clamp and

three screws

NOTE:

Minimum Vent Height

- 12 feet

Maximum Vent Height

- 35 feet

Air Intake

Exhaust

Air intake collar with

label secured with

clamp and three

screws

Exhaust collar secured

with clamp and three

screws

FP1280

Fig. 10 Liner installation.

FP1280a

LHEDV

vent termination

w/zero clearance kit

4/03

6ft.

(183cm)

Spring located in

between the liner

and chimney kit

HEDVCAK

Installation

Secure this

kit with three

(3) screws

provided

HEZC Zero

Clearance Kit

Air Intake

Exhaust

FP1280a

Fig. 11 Liner installation with zero clearance kit.