One Conair Drive ● Pittsburgh, PA 15202 ● 412-312-6000 ● FAX 412-312-6227 ● www.conairnet.com

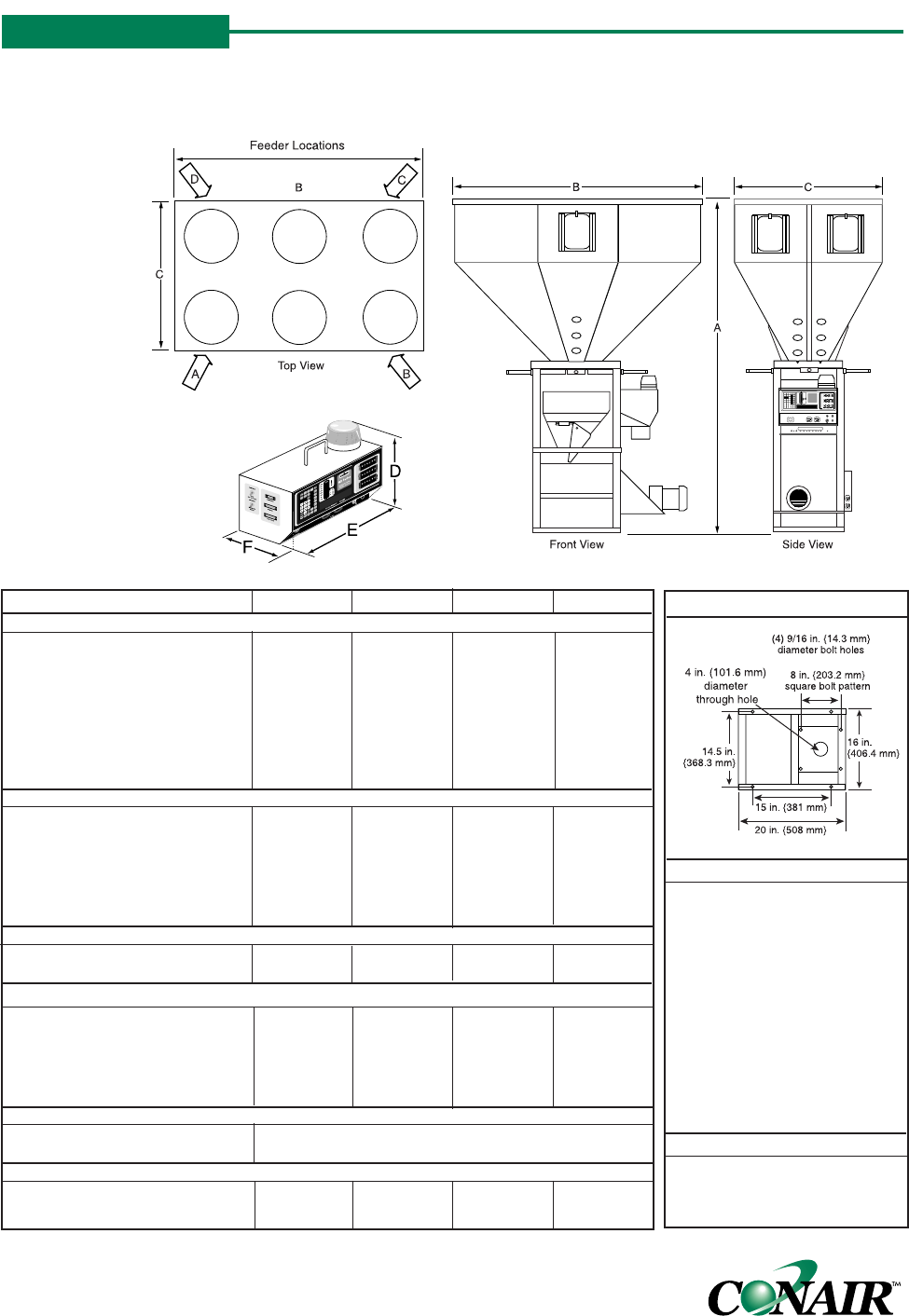

MODELS WSB920 WSB940 WSB950 WSB960

Performance characteristics

Batch size lbs {g} 19.8 {9000} 19.8 {9000} 19.8 {9000} 19.8 {9000}

Maximum throughput lbs/hr {kg/hr}* 5200 {2359} 3300 {1487} 2492 {1132} 2124 {965}

Bin capacity - main ingredient ft

3

{liter} 6.7 {189.7} 6.7 {189.7} 6.7 {189.7} NA

Bin capacity - minor ingredient ft

3

{liter} NA 3.8 {107.6} 3.8 {107.6} 3.8 {107.6}

Maximum number of materials 6 8 9 10

Number of discharge valves 2 4 5 6

Number of additive feeders up to 4 up to 4 up to 4 up to 4

Control software (# of components) 4 or 12 4 or 12 12 12

Dimensions inches {mm}

A - Height above mounting plate 74 {1880.7} 74 {1880.7} 74 {1880.7} 74 {1880.7}

B - Width

†

56 {1421.4} 56 {1421.4} 56 {1421.4} 56 {1421.4}

C - Depth

†

34.4 {875.3} 34.4 {875.3} 34.4 {875.3} 34.4 {875.3}

D - Controller height 11.25 {285.75} 11.25 {285.75} 11.25 {285.75} 11.25 {285.75}

E - Controller width 12.25 {311.15} 12.25 {311.15} 12.25 {311.15} 12.25 {311.15}

F - Controller depth 8.19 {208.03} 8.19 {208.03} 8.19 {208.03} 8.19 {208.03}

Weight lbs {kg}

Installed 480 {218} 480 {218} 480 {218} 480 {218}

Shipping 600 {272.2} 600 {272.2} 600 {272.2} 600 {272.2}

Voltage Running load amps

‡

120V/1 phase/60 hz (control and mixer) 8.5 8.5 8.5 8.5

220V/1 phase/60 hz (control and mixer) 4.3 4.3 4.3 4.3

220V/1 phase/50 hz (control) 0.15 0.15 0.15 0.15

220V/3 phase/50 hz (mixer) 2.2 2.2 2.2 2.2

400V/3 phase/50 hz (mixer) 1.1 1.1 1.1 1.1

Compressed air requirements

Discharge valves 80 psi @ 0.2 ft

3

/min {5.5 bars @ 0.09 liters/sec}; 1/4 in. NPT fitting

Compressed air feeder 40 psi @ 2.0 ft

3

/min {2.8 bars @ 0.94 liters/sec}; 1/4 in. NPT fitting

Maximum loader sizes

§

Number of 20 inch loaders 2 2 2 3

Number of 15 inch loaders 2 4 5 6

GRAVIMETRIC BATCH BLENDERS

WSB 920, 940, 950 and 960 Models

MOUNTING INTERFACE

SPECIFICATION NOTES:

* Maximum throughput rates are

based on using all dispense

valves. Use of feeders for minor

ingredients will reduce this rate.

† Feeders will increase width and

depth dimensions. Please refer

to feeder specification.

‡ Each auger feeder requires an

additional 1 amp @ 120V or 0.5

amp @ 240V.

§ Maximum loader sizes may be

used only when the loader is

adjacent to loaders of a smaller

size.

APPLICATION NOTE:

We recommend using a flow con-

trol valve when mounting the

blender to a stand, surge bin or

hopper.

SPECIFICATIONS

TPBS004/1199

IB04

CONTROL

NOTE: Loader

configuration is

the same for all

models.

APPENDIX B