6-3

The relays in earlier design boards are soldered on and cannot be replaced. Later design boards fea-

ture replaceable plug-in relays. In earlier designs boards, a heat relay (K2) switches 24VAC to the

ignition and gas valve circuits when the controller heat logic circuit calls for heat. Simultaneously, a

blower motor relay (K4) switches 120VAC to the blower motor. In later design boards, relay K3

serves as both the heat relay and blower motor relay.

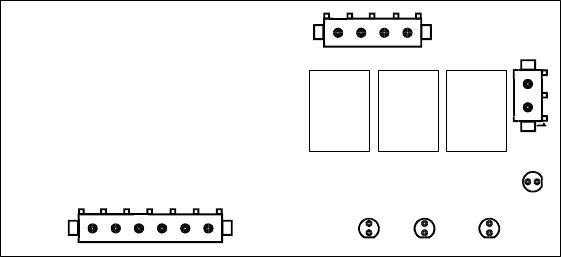

FBRA18 rethermalizers use interface board 806-9592, often referred to as a water board.

INTERFACE BOARD P/N 806-9592

J2

1

1

J1

J3

CYCLE WATER BLOWER

POWER

K3

BLOWER

K2

WATER

K1

HEAT

On interface board 806-9592, the heat (or cycle) relay (K1) switches 24VAC to the ignition and gas

valve circuits when the controller’s heat logic circuit calls for heat and the lower water level sensor

is grounded (i.e., the water level in the cookpot is above the lower water level sensor). If the water

level in the cookpot is below the upper water level sensor, the water relay (K2) closes, switching

power to the normally closed water solenoid valve, causing it to open. When the water level reaches

the upper sensor, the relay opens, cutting power to the valve, causing it to close. The blower relay

(K3) closes and switches 120VAC to the blower motor only when the heat relay (K1) is closed. The

board has four LEDs to assist in troubleshooting. Three of the LEDs (CYCLE, WATER, and

BLOWER) are arrayed along the lower edge of the board. The fourth LED (POWER) is located at

the right edge of the board. When the cycle, water, and blower LEDs are illuminated, they indicate

that the associated relay is closed. The power LED indicates that 24VAC is being supplied to the

interface board by the transformer.

TEMPERATURE PROBE

A temperature probe is located on the front centerline of the cookpot. The probe is a type of thermo-

stat in which the resistance varies directly with the temperature. That is, as the temperature changes,

so does resistance, at a rate of approximately 2 ohms for every 1° of rise or fall. Circuitry in the

controller monitors the probe resistance and controls burner firing when the resistance exceeds or

falls below a programmed temperature (setpoint). The temperature is programmed by means of up

or down arrow buttons on the face of the controller.

WATER LEVEL SENSORS (FBRA18 Only)

A pair of water level sensors is arranged one above the other on the left front of the FBRA18 cook-

pot. When water contacts the sensors they are grounded. The lower sensor acts as a safety device to

keep the burner from firing when there is no water in the cookpot. When the sensor is grounded by

contact with water, a transistor on the interface board is biased and the heat relay (K1) pulls in, sup-

plying power to the blower via relay K3 and to the gas valve via the ignition modules. Grounding

the upper water level sensor causes the water relay (K2) to open. This cuts power to the water sole-

noid valve, which closes, cutting off water flow into the cookpot.