18

SECTION 2

INSTALLATION

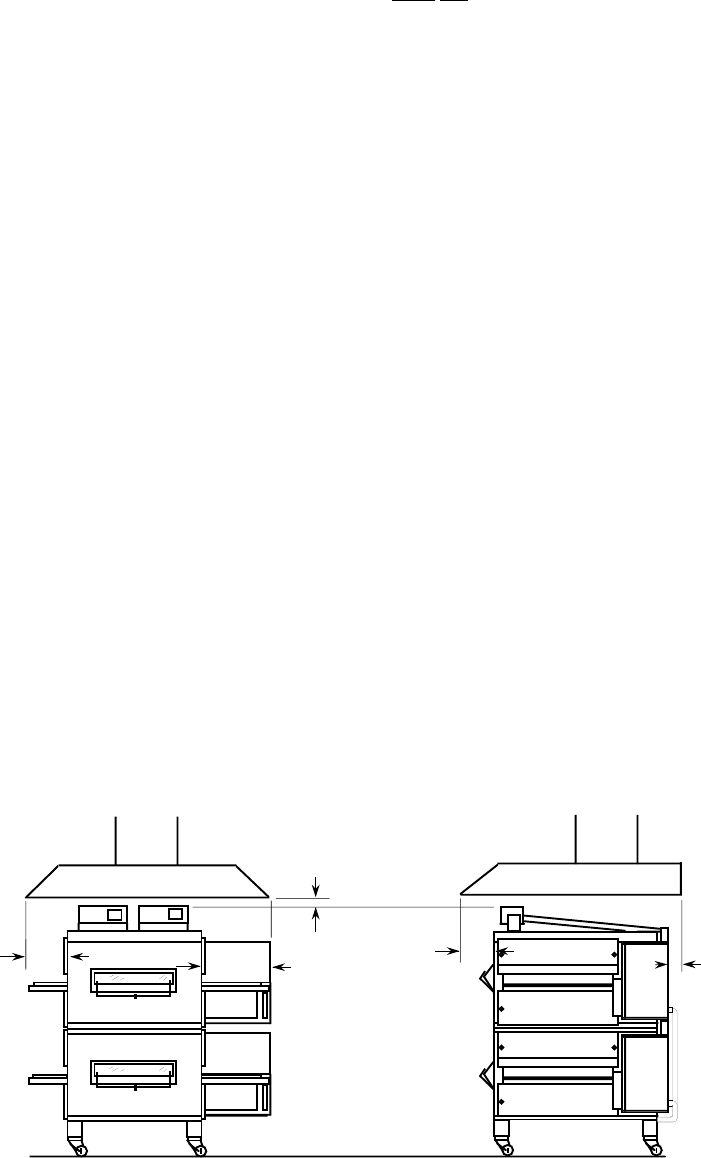

Figure 2-10

Vent Hood

V. VENTILATION GUIDELINES

A mechanically driven ventilation system is required for

the PS200-R68 Series Middleby Marshall conveyorized

gas ovens. The minimum hood canopy dimensions are

outlined below.

Local codes and conditions vary greatly from one area to

another and must be complied with. These are the

“Authority having jurisdiction” as stated by the National

Fire Protection Association, Inc. in NFPA 96-latest edi-

tion. Following are the suggested requirements for good

ventilation. Please remember these are general recom-

mendations or guidelines, you may have a special con-

dition or problem that will require the services of a

ventilation engineer or specialist. Proper ventilation is the

oven owner’s responsibility. Improper ventilation can

inhibit oven performance. It is recommended that the

ventilation and duct work be checked every three months.

Grease filters in the intake of the hood may be required

by local codes.

VENTILATION HOOD

The rate of air flow exhausted through the ventilation

system is generally between 1400 and 2500 CFM, but

may vary depending on the oven configuration and hood

design. To avoid a negative pressure condition in the

kitchen area, return air must be brought back to replenish

the air that was exhausted. A negative pressure in the

kitchen can cause heat related problems to the oven

components as if there were no ventilation at all. The best

method of supplying return air is through the heating,

ventilation and air conditioning system (HVAC). Through

the HVAC system, the air can be temperature controlled

for summer and winter. Return air can be brought in

directly from outside the building, but detrimental affects

can result from either extreme seasonal hot and cold

temperature from the outdoors.

NOTE: Return air from fan driven system within the hood

must not blow at opening of bake chamber or poor oven

baking performance will result.

VENTILATION CAPTURE TEST

It is recommended that a 30 second smoke candle test be

performed on your ventilation hood system. Follow the

steps below to complete the ventilation smoke test.

All tests are to be done on single ovens or lower units of

a double oven. We recommend you wear protective

gloves when performing this test. At no time should food

be present when the smoke test is being conducted. Also

check that no fire suppression system will be activated by

the smoke.

1. Turn ventilation system on.

2. Turn oven(s) on and allow to heat up to customers

normal operating temperature, or a minimum of 480°F

(248°C).

3. Turn conveyor off. Place a 30 second smoke candle

in a pie or cake pan which is no higher than 3" (76mm).

4. Open the front oven window. Next, light the smoke

candle in the pan and then slide the pan into the center

of the bake chamber on the conveyor belt and close the

window.

5. The ventilation hood should capture 90% to 100% of

the smoke produced by the candle.

8”

203mm

2”

51mm

minimum to

allow stacking

of ovens

3”

76mm

10”

254mm

17-1/2”

445mm