S3F84B8_ALL-IN-ONE IH COOKER_AN_REV 0.00 2 HARDWARE IMPLEMENTATION

2-10

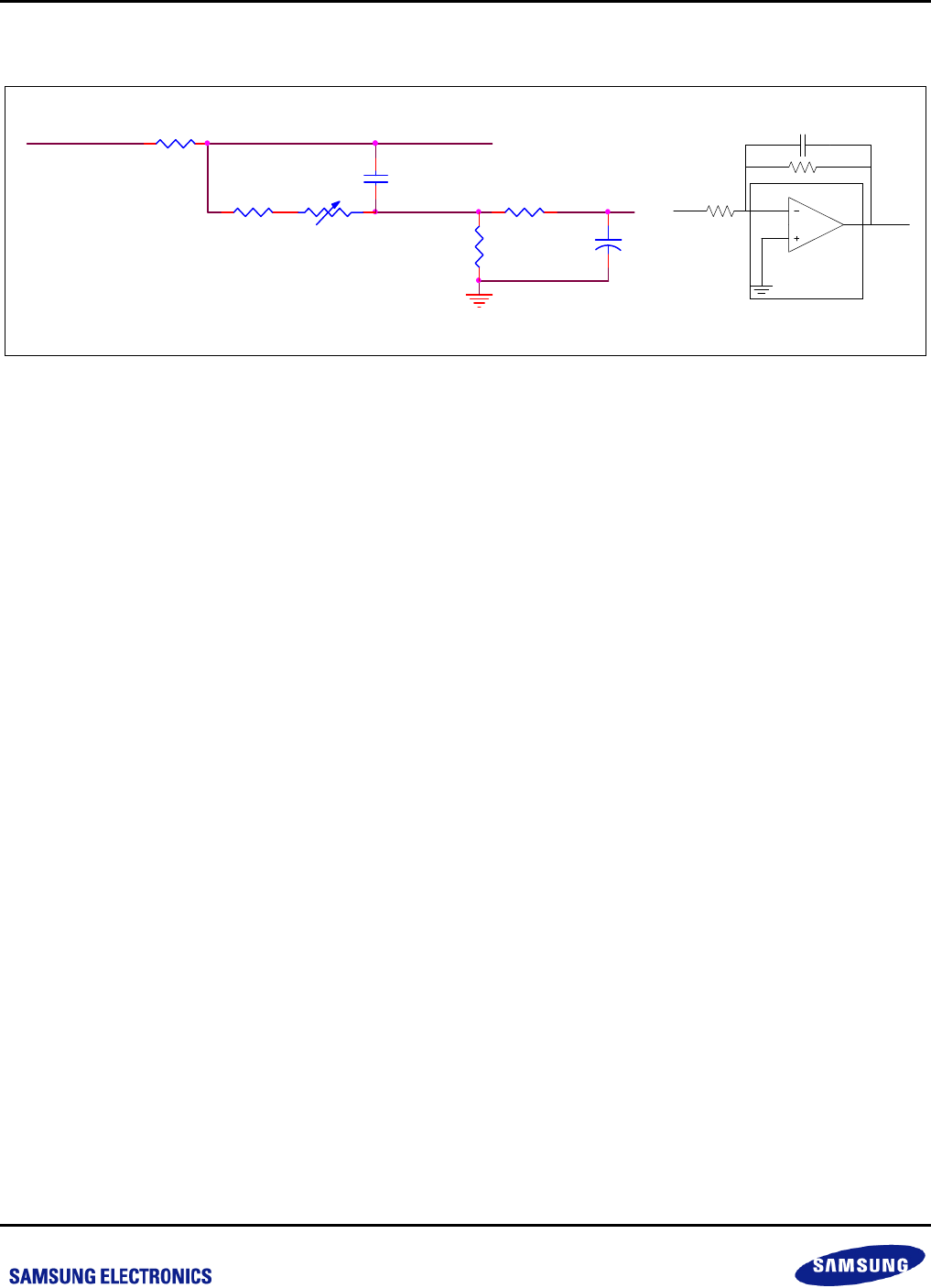

2.4.2 CURRENT MEASUREMENT

R4 1K

OPA_O

R13 36K

RW1

10K

OPA_N

C10

104J

SYS_I

+

C12

1uF/16V

CURRENT

R14 100K

R15

22K

S3F84B8

R

f

R

1

OPA

_

N

OP

A

_

P

OP

A

_

O

Gain

=

-

R

f

/

R1

Figure 2-6 Current Measurement Circuit

In the IH cooker system, the current can go as high as 10A. To avoid excessive energy loss, a constantan is used

to change the current signal to voltage signal, which is then amplified by the integrated OPA. Finally, the amplified

signal enters the ADC module. Note that the signal (OPA_N) reaching OPA is negative as compared to MCU

GND. Therefore, OPA has to work as an inverting amplifier with negative gain.

Either the OPA offset or the resistance deviation can lead to inconsistency of output power among different chips.

To get precise power control, two calibrating methods are used. In hardware, a variable resistor (RW1) is chosen,

whereas in software algorithm, the overall offset is measured and calculated before the system starts working. It

likes the quiescent bias that should be removed during normal operation. This way the output power can be

controlled within 10W deviation.