VHX SERIES STEAMER - ELECTRICAL OPERATION

F24700 (October 2001) Page 44 of 68

Boiler Operational Status (LED Indicator)

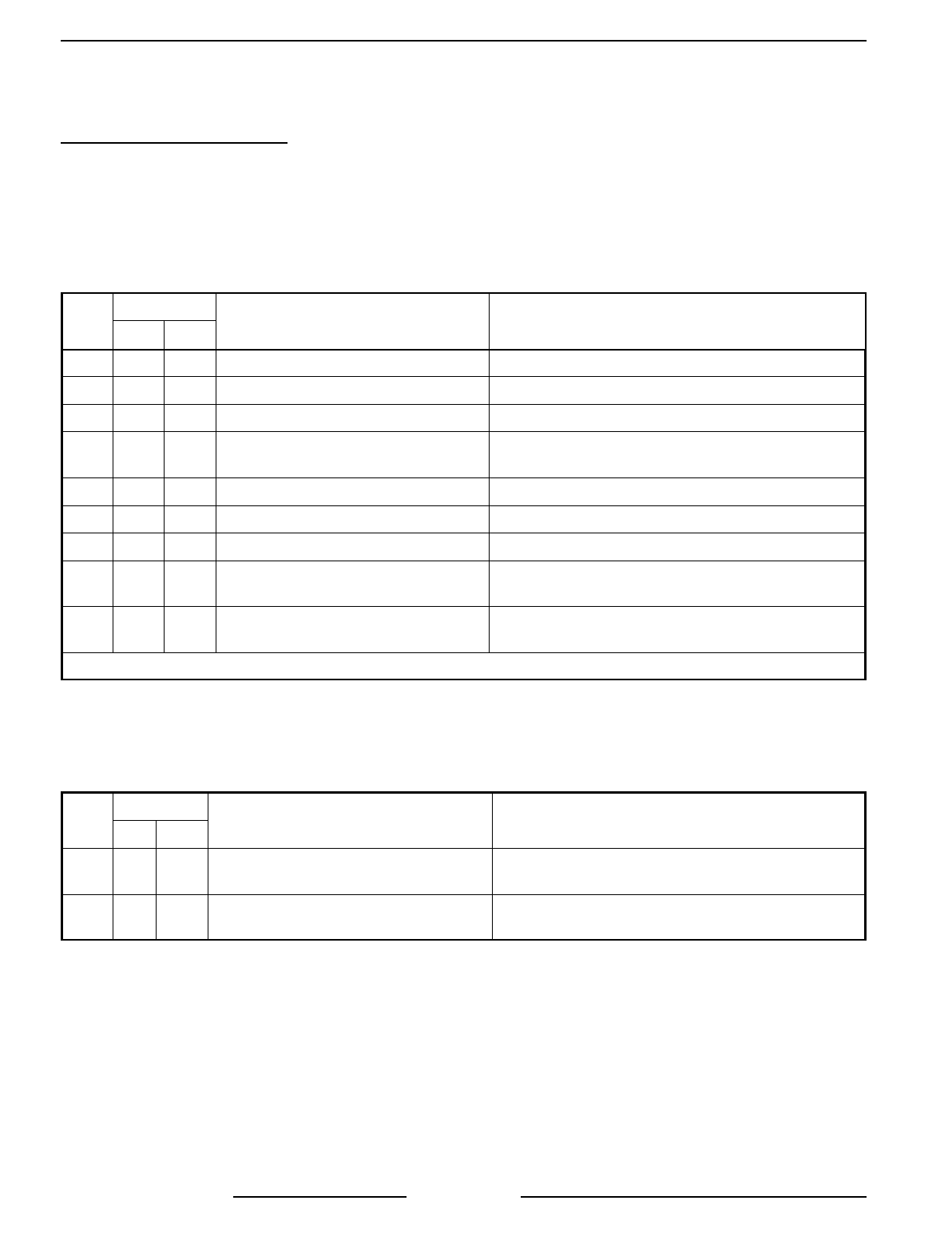

Use the tables below to determine the operational status of a component or condition by utilizing the LED

indicators on the board. The operational state’s are divided into categories A thru F.

Initial Conditions: (STATE A)

- 120V, water and gas supplied to steamer

- Power Switch ON

- HIGH PRESS and LOW WATER lights ON (amber, front control panel)

- Green “ready” light OFF

- Water is filling boiler

LED

STATUS

DESCRIPTION ELECTRICAL COMPONENTS CONDITION

ON OFF

N1 X 24V supplied to relay board

N2 X Aux Water level not satisfied Aux. LLCO contacts OPEN

N3 X High limit pressure switch satisfied K2 energized - K2(1) CLOSE, K2(2) CLOSE

N4 X

Aux Water level is initially not

satisfied. Therefore N4 is OFF

K1(1) OPEN

N5 X Reset switch is not being energized

N6 X Aux Water level is/was not satisfied K3 not energized

N7 X Reset switch is not being energized

N8 X

High Limit pressure switch is/was

not satisfied

K4 not energized

N9 X

Cycling pressure switch is closed

and unit is calling for HEAT

N10 through N17 remain OFF

Aux Water Level Satisfied: (STATE B)

- Green “ready” light ON (ready light remains ON, until a LOW WATER or HIGH PRESSURE) condition occurs.

Status of LED’s are the same as “Initial Conditions” except for the following:

LED

STATUS

DESCRIPTION ELECTRICAL COMPONENTS CONDITION

ON OFF

N2 X Aux water level is satisfied

Aux. LLCO relay energized, Aux. LLCO contacts

CLOSED

N4 X

Aux LLCO water level and high limit

are satisfied. Green “ready” light ON.

K1 energized - K1(1) CLOSE

Reset Engaged: (STATE C)

User presses/engages the RESET button

- LOW WATER and HIGH PRESSURE lights OFF (amber, front control panel)