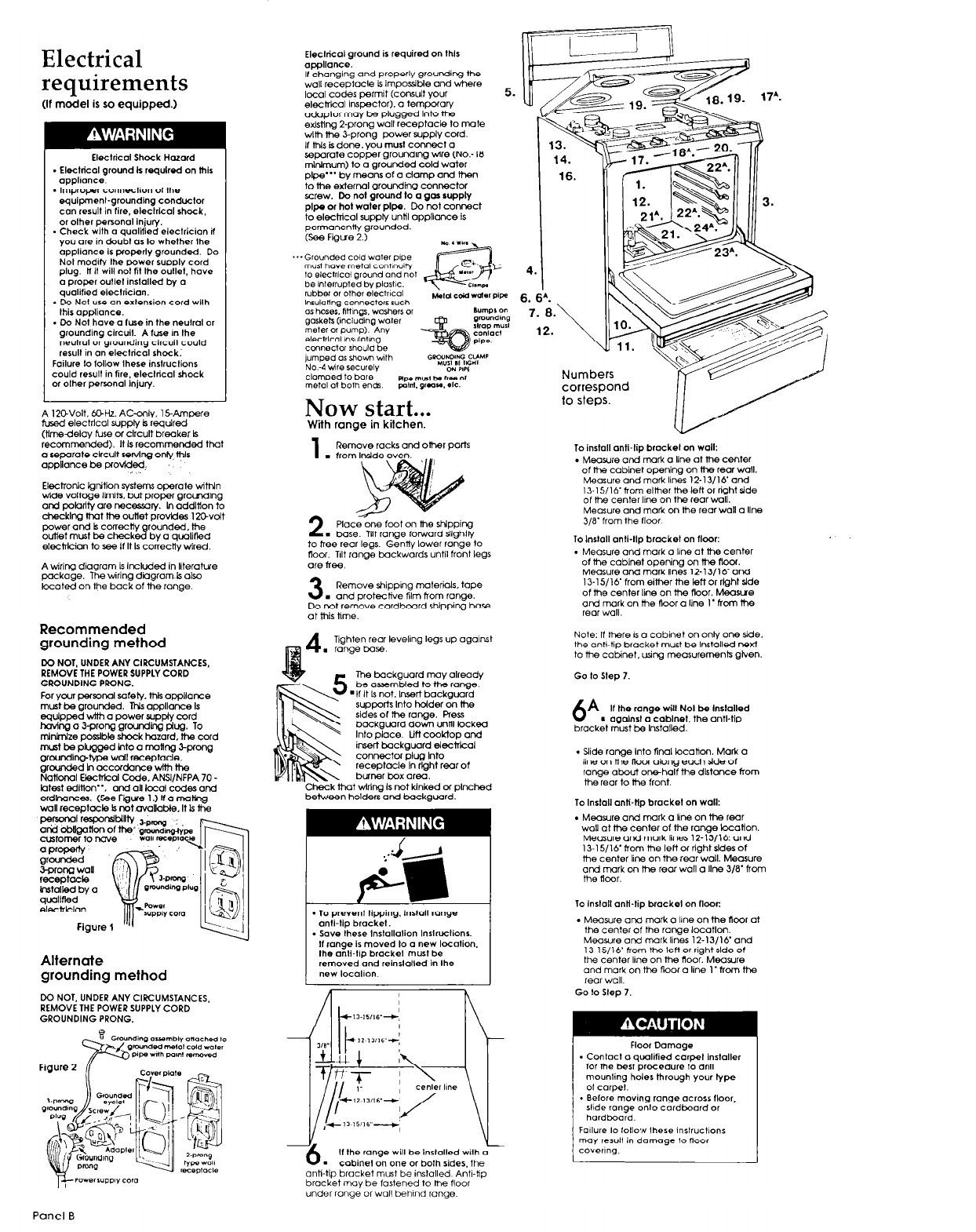

Electrical

requirements

(If model is so equipped.)

Eleclricol Shock Hozord

- Electrical ground k required on this

appllonce.

- Improper conneckon 01 the

equipment-grounding conductor

can result in tire, electrical shock,

or other personal injury.

- Check with o qualitied electrician it

You ore in doubt (II lo whether the

appliance is property grounded. Do

Not modity the power supply cord

plug. iT it will not fit the outlet. have

o proper outlet inslalled bY o

qualified electrician.

. Do Nol use an extension cord wilh

this applionca.

. Do Not have (1 fuse in the neutral or

grounding circtil. A fuse rn the

I-----’

neutral or grounding circuit could

result in on electrical shock:

Failure lo tallow lhese instructions

could result in fire, electrical shock

or olher personal Injuly.

A 1’2OVolt. &Hz. AC-only. 15.Ampere

haed electrical supply ls required

(Hmedeloy tise or &cult breaker Ls

recommended). It Is recommended that

a separate Clrcult serving only Hlls

appliance be ptovlded,

Electronic !gnit!an systems operate tithln

wide voltage Ilmlts. but proper arodina

and pokxiti are necesury: h addition G

checking that the oultet provktes 12Dvdt

power and k correcIiy grounded, the

otiet must be checked by a qwlit?ed

electrkian to zee II It Ir, correcny wired.

A tiring diagram b Included in literature

pcckage. The wiring diagram Is alsa

located on the back of the range.

Recommended

grounding method

DO NOT. UNDER ANY CIRCUMSTANCES.

REMOVE THE POWER SUPPLY CORD

GROUNDING PRONG.

For Your personal safety. mls appliance

must be grounded. MS appliance Is

eaukwed with a power X&Y cord

h&l& a 3pro~~grwndlng plug. To

mlnlrrdze possible shock hazard. tlw cord

nx6t be plugged Into a mating J-prong

groundln@ype wall receptacle,

grcwded In accordawe m the

NaHanal Electrical Code. ANSI/NFPA 70 -

latest edltlcn”. and all local codes and

ordlnonces. (See Flgws 1.) n a maw

wall receptacle knot cwaUaMe. It Is the

electrklon.

Alternate

grounding method

Do NOT. UNDER ANY CIRCUMSTANCES.

REMOVE THE POWER SUPPLY CORD

GROUNDING PRONG.

Electrical ground is required on this

oppllance.

II changing and properly grounding the

wall receptacle ir impossible and where

local codes permit (consult Your

5.

electrkal inspector). a tempotory

adaptor may be plugged Into the

extstlng 2.prong wall receptacle to mate

tim me

J-prong power y~p@Y cord.

If

mls

is done.You must connect a

saporate copper grounding tire (No.-18

mlnlmum) to a grounded cold water

pipe”’ by rneanr of a clamp and Men

to

me

external grounding connector

screw. Do not ground to a gas supply

pipe or hot water plpe. Do not connect

to electrtcal supply unti appliance is

permonentty grounded.

(see Film 2.)

- . I/..

. ..Gro”“ded cola water ptpe

must have metcl conti”“ltV

to electrlcoi ground and no,

be lnterrup+ed by ploshc.

rubber or other elec+ricoI

I~lanng Connectorssuch

OS hoser. hhrngs. Washers or

gaskets (inciudlng water

meter or pump). Any

electrIcal lnsularlng

cmnector should be

jumped 08 show- with

No.d wire securelv

Now start...

With range in kitchen.

1 R

emove racks and oltwr parts

. fromltideoven.

to tree rear legs. Gently lower range to

floor. Tilt range backwards until front legs

are free

3

Remove shipplng materials. tape

. and protective film horn range.

Do not remove cardboard shipping base

at mis hme.

The backguard may already

be assembled to the range.

g If it Is not. Insert backguard

supports Into holder on the

sides 01 the range. Press

backguard down unltl locked

Into place.

Lin

cooMop and

insert backguard electikal

connector plug Into

receptacle In rtght rear 01

burner box area

Check that wtrlng Is not klnked of plnched

between holders and bockguard.

. To prevent tipping. tnstall range

anti-tip bracket.

- Sow these Instollalion Inslructions.

II range is moved to a new location.

the or&tip brackel must be

removed and reinslalled in the

new localion

anti-tip bracket must be installed Anti-hp

bracket may be fastened to the floor

under range or wall behmd range

16.

4.

Numbers

correspond

to steps.

To install anti-tip bracket on wall:

l

Measure and mark a line at the center

ol i% cabinet opening on the rear wall.

Measure and mark lines 12.13/16’ and

13.15116’ tram either the left or right side

of me center line on the rear wall.

Measure and mark on Ihe rear wall a line

3/B’ from the tloor

lo Instoll anti-tlp bracket on 11-r:

a Measure and mark a line at me Center

ol the cabinet opening on the Hoor.

Measure and mark lines 12-13/16’ar?d

13.15/16’ from either the lett or rtght side

of me center line on the Roar. Measue

arc mark on me floor a line I’ from the

rear wall.

Note: II ttwe Is a cabinet on only one side.

the anti-tip bracket must be Installed rw?.i

to the cabinet, using measurements gtven.

Go to Step 7.

II Hw range will Not be Installed

. agolnst a cabinet. the ant+tip

bracket must be Installed.

. Slide range Into final locahon. Mark a

lhne on the Rooi along each side of

range about onehalf me distance from

me rear to the Iront.

To Install anti-ttp brackel on wall:

l

Measure arc mark a lane on H-6 rear

wall at the center of

mhe ran33

location.

Measure and mark lines 12-113/l& and

13.15/16’ horn the lett or right sides of

me center line on the rear wall. Measure

and mark on the rear wall a line 310’ horn

me floor.

lo Install antl-tip brackel on Iloor:

. Measure and mark o lane on the noor at

the center of the range locatIon.

Meowreond morkllnes 12.13116’ond

13.15/16’ from the left or rlght’slde of

the center line on me floor. Measure

and mark on the floor a line 1’ horn ti

rear wall.

Go to Step 7.

Floor Damage

- Conloct o qualified carpet installer

tor the best procedure to drill

mounling holes through your type

01 carpet.

- Betore moving range across rIoor.

slide range onto cordbxxd or

hordboard.

Fo~lure lo totlow lhese instructions

may result in damage to tloor

CoverIng.

Panel B