2-2

IGNITOR SYSTEM OVERVIEW

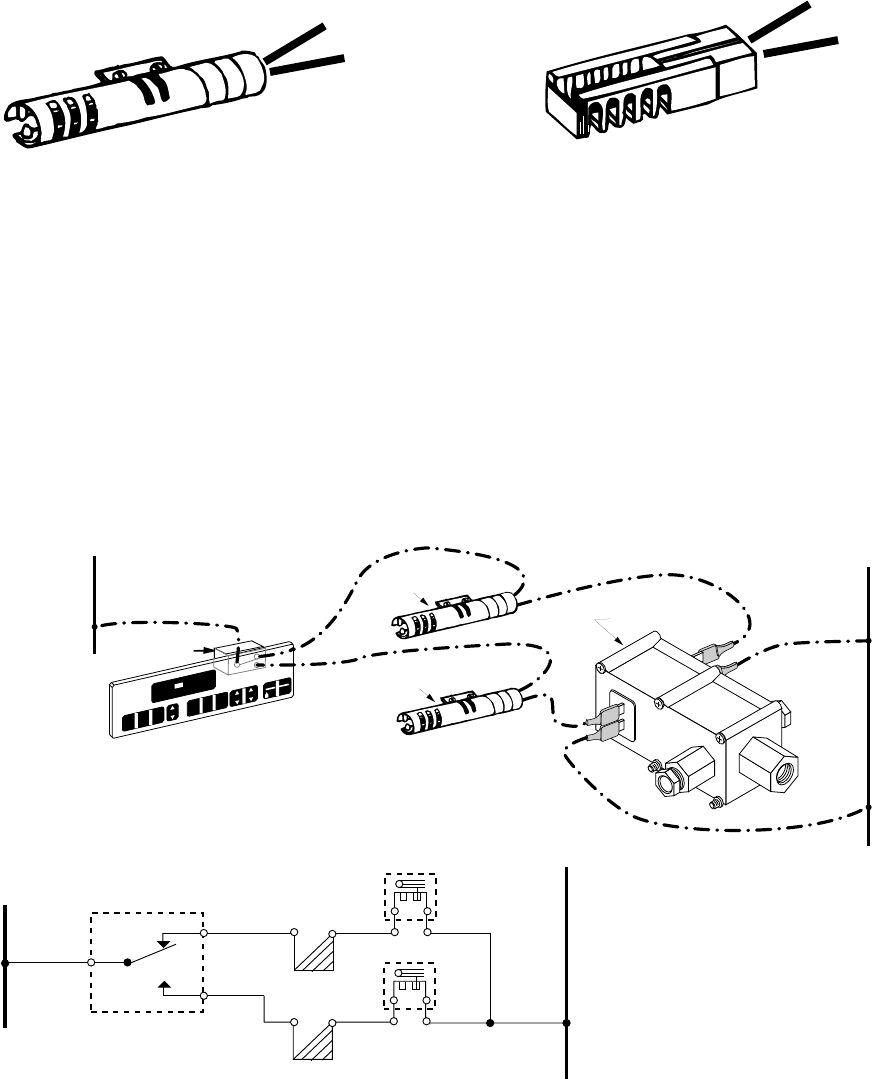

A Carborundum ignitor uses a round design,

and limits the operating current flow to be-

tween 2.5 and 3.0 amperes.

A Norton ignitor uses a rectangular design,

and limits the operating current flow to be-

tween 3.2 and 3.6 amperes.

This gas range uses two Carborundum igni-

tors to provide a source for igniting gas from

the bake and broil burners. Norton ignitors

were previously used in the Whirlpool gas

ranges, and both of these ignitors operate the

same way. The only differences are in the

design (see the illustrations), and in the cur-

rent ratings.

Norton Ignitor

3.2 - 3.6 Amps

Carborundum Ignitor

2.5 - 3.0 Amps

The oven ignitor system in these Whirlpool

gas ranges has the following three main com-

ponents, and is wired in a series-parallel cir-

cuit (see the illustration below):

1. An Electronic Oven Control (EOC).

2. Two Carborundum Ignitors (Bake &

Broil).

3. Dual Gas Safety Valve.

All of the self-clean gas ranges use these

components. When the EOC is set to the bake

or broil mode and a temperature is selected,

the relay on the EOC closes, and provides

power to the ignitor. With power applied, cur-

rent flows through the ignitor circuit, and the

ignitor begins to heat and glow.

IGNITOR SYSTEM OPERATION

BROIL IGNITOR

BAKE

HR

MIN

CUSTOM

BROIL

AUTO

CLEAN

CLOCK

TIME

DELAY

TIMER

SET

STOP

TIMER

OFF

OFF

CANCEL

S

TA

RT

E

N

TER

5 SEC

HEAT BAKE BROIL LOCKED CLEAN TIMER

O

F

ON

PF

ELECTRONIC

OVEN CONTROL

(EOC)

L1

N

RELAY

DUAL GAS

SAFETY VALVE

BAKE IGNITOR

L1

N

BAKE VALVE

BROIL VALVE

BAKE IGNITOR

BROIL IGNITOR

ELECTRONIC OVEN CONTROL

RELAY