4-2

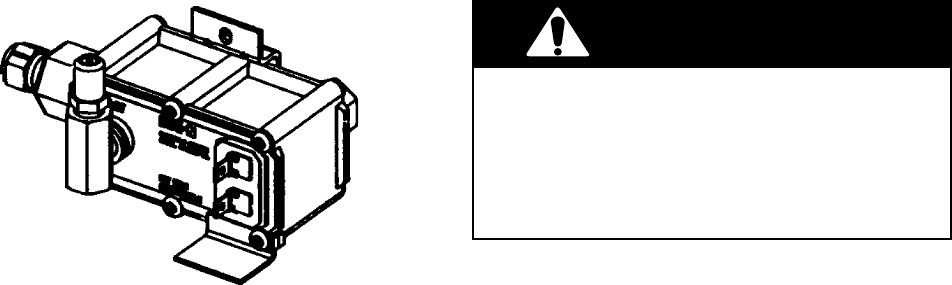

DUAL GAS SAFETY VALVE

1. Broil burner operates, but the bake burner

will not come on.

a) Place the oven in the BAKE mode, set

the oven thermostat to 350 degrees,

and observe the bake igniter. If the

igniter glows, go to step c. If the igniter

does not glow, go to step b.

b) Disconnect power, remove the wires

from the bake side of the gas safety

valve, and connect an ohmmeter

across the terminals of the gas safety

valve. If the meter reads approximately

1 Ω, the problem is in another compo-

nent of the bake circuit. If the meter

reads infinity, replace the gas safety

valve.

c) Connect an ampmeter to the bake cir-

cuit. If the meter reads less than 3.2

amps, replace the bake igniter. If the

meter reads over 3.2 amps, replace

the gas safety valve.

WARNING

Test Procedure

Description

The purpose of the gas safety valve is to control

gas to the bake and broil burners.

The dual gas safety valve has one gas input

and two gas outlets, one for the bake burner,

and one for the broil burner. It uses two iden-

tical electrically-operated devices, one for each

outlet, to control the gas flow. The devices are

made of an electric heater coil wrapped around

a bimetal strip. One end of the bimetal is

riveted to the plate of the valve, and the other

end has a rubber seal attached to it that cov-

ers a gas outlet. At room temperature, the

spring force of the bimetal presses the rubber

seal against the gas outlet. When current flows

through the heater, heat is applied to the

bimetal strip. The amount of heat necessary to

warp the bimetal enough to open the valve,

requires a minimum of 3.2 amps of current

flow in the circuit. The reason the valve is

designed not to open below 3.2 amps, is to

insure that the temperature of the oven igniter

is above 1800˚ F before the valve opens. Only

one burner in the oven may be in operation at

one time.

Electrical Shock Hazard

Disconnect from electrical supply before ser-

vicing unit.

Failure to do so could result in death or

electrical shock.