ZANUSSI

P R O F E S S I O N A L

FORCED AIR CONVECTION OVENS

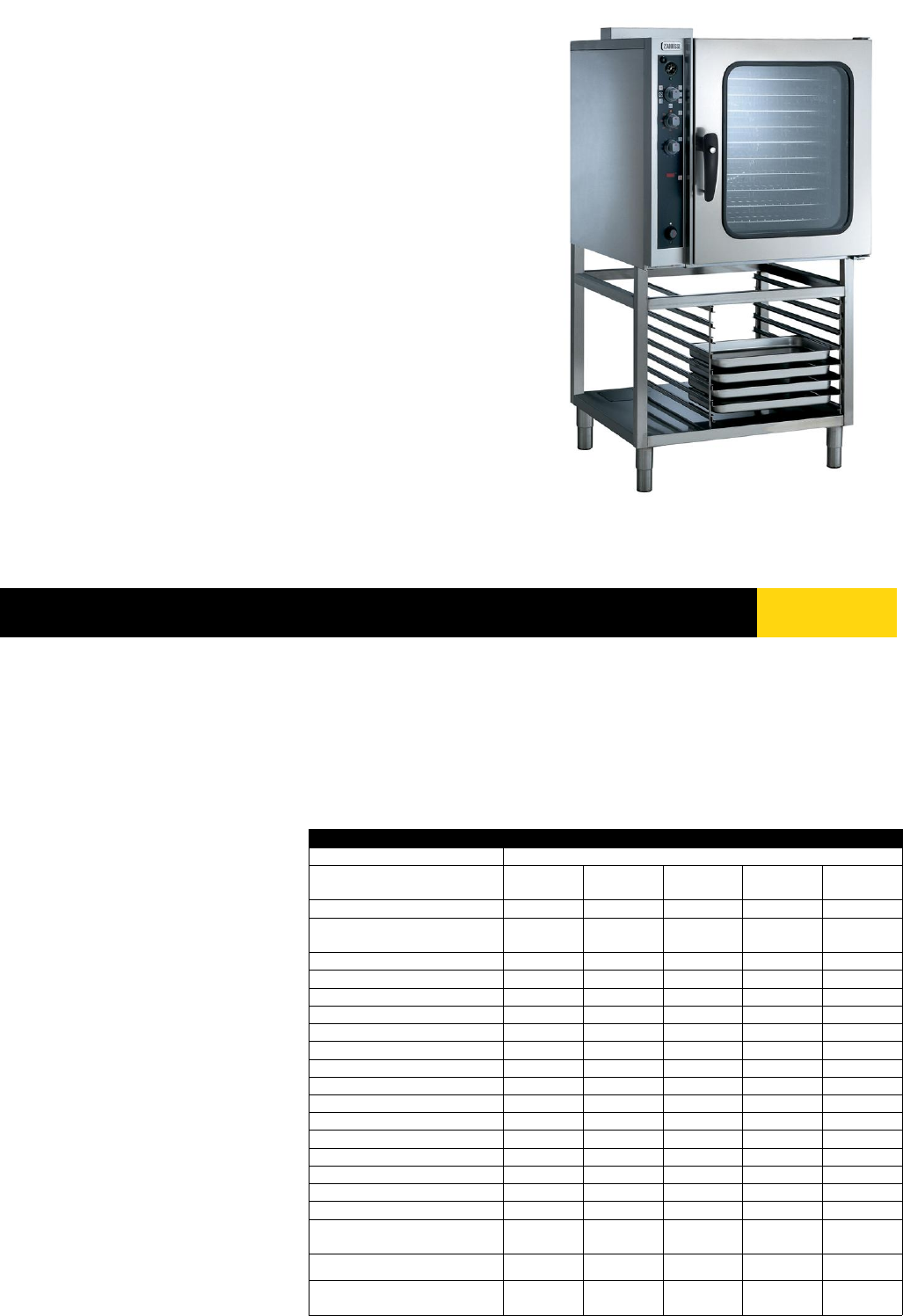

FCF-10 1/1

240201 + stand

60 MM PITCH SIDE HANGERS

10X1/1 ELE.OVEN

1 1 1 1 1

INCLUDED ACCESSORIES

Supply voltage 220/230 V,

1N, 60

220/230 V,

1N, 50

400 V, 3N,

50

400 V, 3N,

60

230 V, 3, 50

Net weight - kg. 136 136 121.2 121.2 121.2

installed-electric 0.35 0.35 17.3 17.3 17.3

gas 18.5 18.5

Power - kW

height 680 680 680 680 680

depth 479 479 503 503 503

width 590 590 590 590 590

Internal dimensions - mm

height adjustment 80 80 80 80 80

height 970 970 970 970 970

depth 900 900 900 900 900

width 890 890 890 890 890

External dimensions - mm

Convection l l l l l

Shelf capacity 10 10 10 10 10

Type of grids 1/1

Gastronorm

1/1

Gastronorm

1/1

Gastronorm

1/1

Gastronorm

1/1

Gastronorm

Power supply Gas Gas Electric Electric Electric

FCF101G6

240269

FCF101G

240201

FCF101E

240206

FCF101ENS

240227

FCF101ELN

240212

CHARACTERISTICS MODELS

TECHNICAL DATA

RANGE

COMPOSITION

A range which combines experience and

innovation; is new in performance, excellent

in quality and economical in use. The ideal

solution for establishments requiring ovens

with high output, compact dimensions,

flexibility of use, high levels of automation,

reduced energy and condiments

consumption, up-to-date design and

maximum reliability.

The range consists of five 10 grid 1/1 GN

models, three electric and two gas, ideal for

all types of traditional oven cooking, roast

meat, cakes, pizzas, fish, vegetables, grilled

food, "au gratin" cooking and the

reconditioning of chilled and frozen food.

FUNCTIONAL AND

CONSTRUCTION

FEATURES

� The Flow Channel ventilation system

guarantees uniform cooking of food by

optimizing the flow of air and diffusion of heat

throughout the oven chamber, it also means

that it is possible to cook different foods at

the same time without transfer of smell or

flavour.

� External panelling, door, sides and upper

part in 304 AISI stainless steel; the cooking

chamber, grid supports, diffusers, and the fan

walls are in 430 AISI stainless steel; the

double glazed door is made from tempered

glass and gives an excellent view of the

cooking load and a door opening safety

device. The oven chamber has rounded

corners and no joins for ease of cleaning.

� A series of automatic and manual

controls, are supplied as standard, which

allows a lot of oven operations to be

automated without hindering the creativity of

the chef.

� The optimised relationship between

installed power, output and speed of cooking

means that excellent results can be achieved

in terms of economy of use as well as the

production in a short amount of time of a high

quantity of food and all this with an oven heat

up time of about 6 minutes.

� The heating system in the gas models

consist of atmospheric burners; safety is

guaranteed by flame failure device; main

burner ignition by pilot light; piezoelectric

ignition of the pilot light. The heating system

in electric models consists of "Incoloy"

armoured elements positioned on the

convector unit.