11-600205211REVA

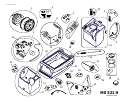

7 Allow the heat exchanger two minutes to reach operating temperature. The red light (1) will go

out when the heater has reached maximum operating temperature. The light will be ON most of

the time while you are cleaning.

8 Turn the pump ON (4) and set the pressure selection switch (3) to the desired spraying pressure:

Carpet at 300 PSI or Upholstery at 50 PSI.

9 Turn the vacuum ON (2). The motor will start slowly. This will increase the life of the motor and

prevent a large current surge from tripping the circuit breaker in the wall.

10 Begin cleaning using the correct hoses and tool.

11 Use defoamer in the recovery tank any time foaming occurs.

12 Monitor the water level in the solution tank.

Do not let the pump run dry.

13 When the solution tank gets low, turn the pump and the vacuum off (3 & 4), fill the solution tank,

empty and clean the recovery tank.

14 When finished with the job, remove any unused solution from the solution tank by vacuuming it

into the recovery tank. Run a few gallons of clean water through the system.

15 Drain the recovery tank by placing the dump hose over a drain, or into a bucket, and remove the

hose cap.

16 Disconnect the hoses from the cleaning tool, and reel the hoses up onto the hose spool.

NOTE: to remove the reel, with the hoses, from the machine, pull the vacuum hose loose from the

hose barb on the front of the tank. Disconnect the solution hose quick coupling. Push the vacuum

hose into the center of the spool. Grasp the spool on both sides, and lift it off the machine. NOTE:

before servicing any component in the base cabinet, the hoses and spool must be removed from the

machine before the tanks can be lifted open.

CAUTION: to avoid vacuum motor damage, always use a defoamer any time foam is present.

BALL FLOAT VACUUM SHUT-OFF:

Prior to using the machine, always check that the float filter is clean and the ball can travel freely.

When the recovery tank is full, the ball float will rise and will shut off the vacuum flow to prevent any

more water from entering the tank. Turn off the vacuums, and empty the recovery tank.

NOTE: if foam is present, or if the ball float is prevented from rising, the float will not be able to stop

the air flow, and the tank may over fill. Water damage to the vacuum motors is not covered by

warranty.

CAUTION: if foam or water comes out the vacuum exhaust, turn

the machine off immediately