SERVICING INSTRUCTIONS — DIAGNOSTICS & TROUBLESHOOTING)

If the E-Max™ LX goes into an error mode as outlined below, it

will probably be necessary to reset the brewer in order to test

individual components. Note the reset procedure below:

* FOR “LOW WATER” OR “OVERHEAT” ERRORS:

PRESS & HOLD CANCEL FOR 3 SECONDS, OR

RE-ENERGIZE THE BREWER (i.e. unplug for a few

seconds, the plug in again.)

* FROM “VALVE FAULT” ERROR: THE BREWER MUST

BE RE-ENERGIZED Using the CANCEL button will not

reset the brewer from “Valve Fault”.

IMPORTANT: The following

troubleshooting suggestions are for

operator reference only.

All servicing and/or repairs must be

performed by qualified service

personnel.

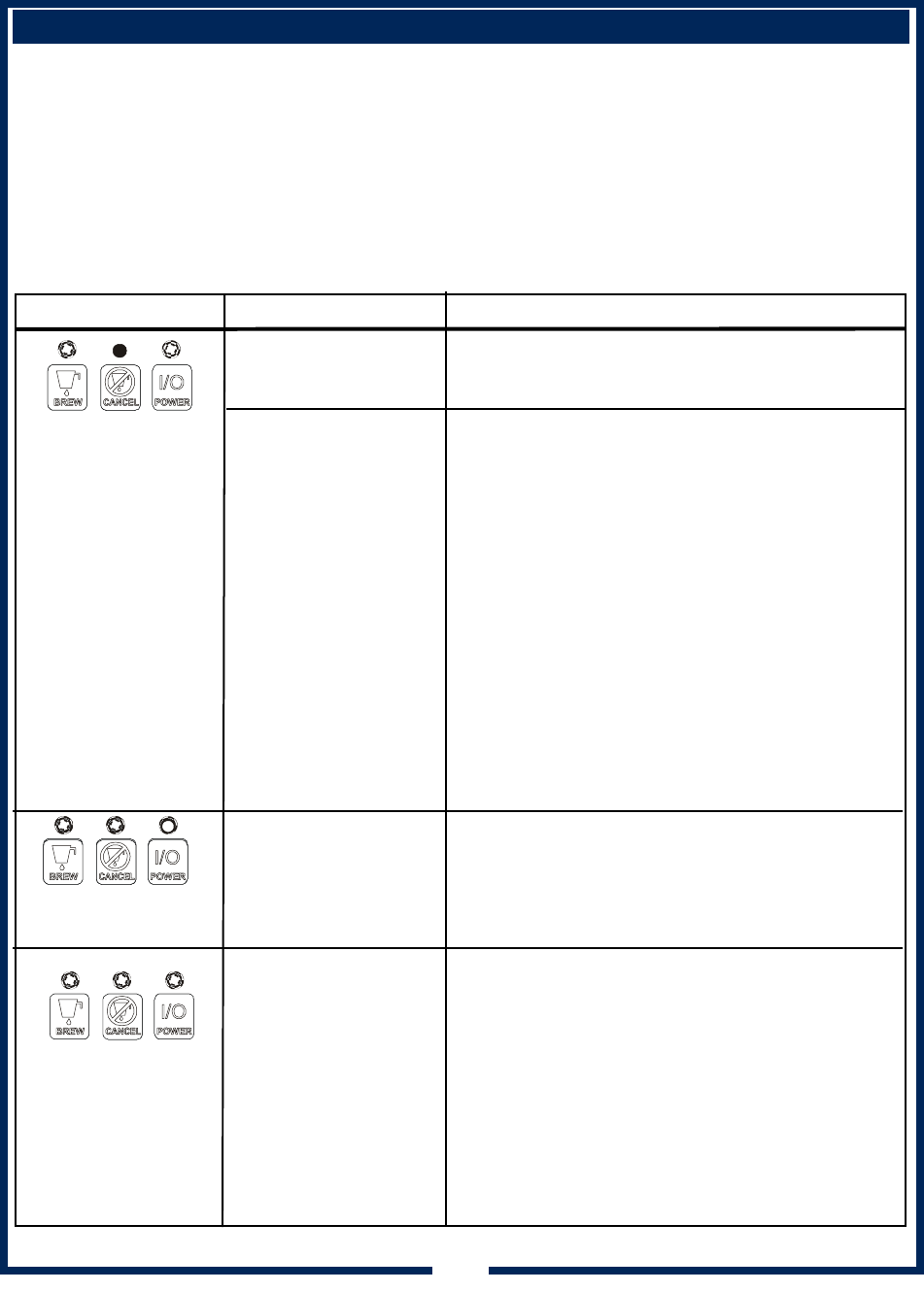

FLASHING LIGHTS

BREW light and

POWER light

flashing

BREW light and

CANCEL light flashing

BREW light, CANCEL

light and POWER light

flashing

ERROR

LOW WATER TEMP

(Not an error)

LOW WATER LEVEL:

Inlet valve has been on

and no water sensed:

a. During regular

operation for 60

sec., or

b. during startup for

4-1/2 min.

VALVE FAULT:

Detection of a problem

with the wiring to the

valve or of the valve

switching system.

OVERHEAT:

Water temperature has

exceeded 210ºF

POSSIBLE PROBLEM & CORRECTIVE ACTION

1. Water has not reached Precise Temperature

for Brewing™. WAIT UNTIL WATER

TEMPERATURE HAS RECOVERED.

1. Sleeve on level sensing probe gasket is too

long or sensor not pushed down fully. Sensor

should protrude beyond sleeve 1/4”.

REMOVE TANK LID, CUT SLEEVE TO

PROPER LENGTH. MAKE SURE SENSOR

IS FULLY PUSHED DOWN.

2. Level sensor may be pulled out of tank.

REINSTALL SENSOR.

3. Wiring to sensor may be disconnected or

faulty. REPAIR WIRING

4. Level sensor may be encrusted with scale or

lime build-up. CLEAN SENSOR (use chemical

de-liming. Scraping or sanding will damage

the sensor.

5. Water supply may be shut off, or is incapable

of filling the tank in the allotted time.

RESTORE WATER SUPPLY.

1. Wiring to either inlet or dump valve not properly

connected. CHECK WIRING / CONNECTORS.

2. Controller has two switches for each valve, one

or both has been detected as failing on.

REPLACE CONTROL BOARD.

1. Brew temperature may be too close to max.

temp. Brew temperature should be no higher

than 205ºF. LOWER BREW TEMPERATURE

SETTING.

2. Triac may have failed on, and water continues

to heat even after controller has tried to turn

heating element off. CHECK TRIAC,

REPLACE IF REQUIRED.

3. Probe may be defective. TEST ACTUAL

TEMPERATURE TO VERIFY. REPLACE

PROBE OR REPAIR WIRING AS REQUIRED.

15