FACTORY AUTHORIZED SERVICE

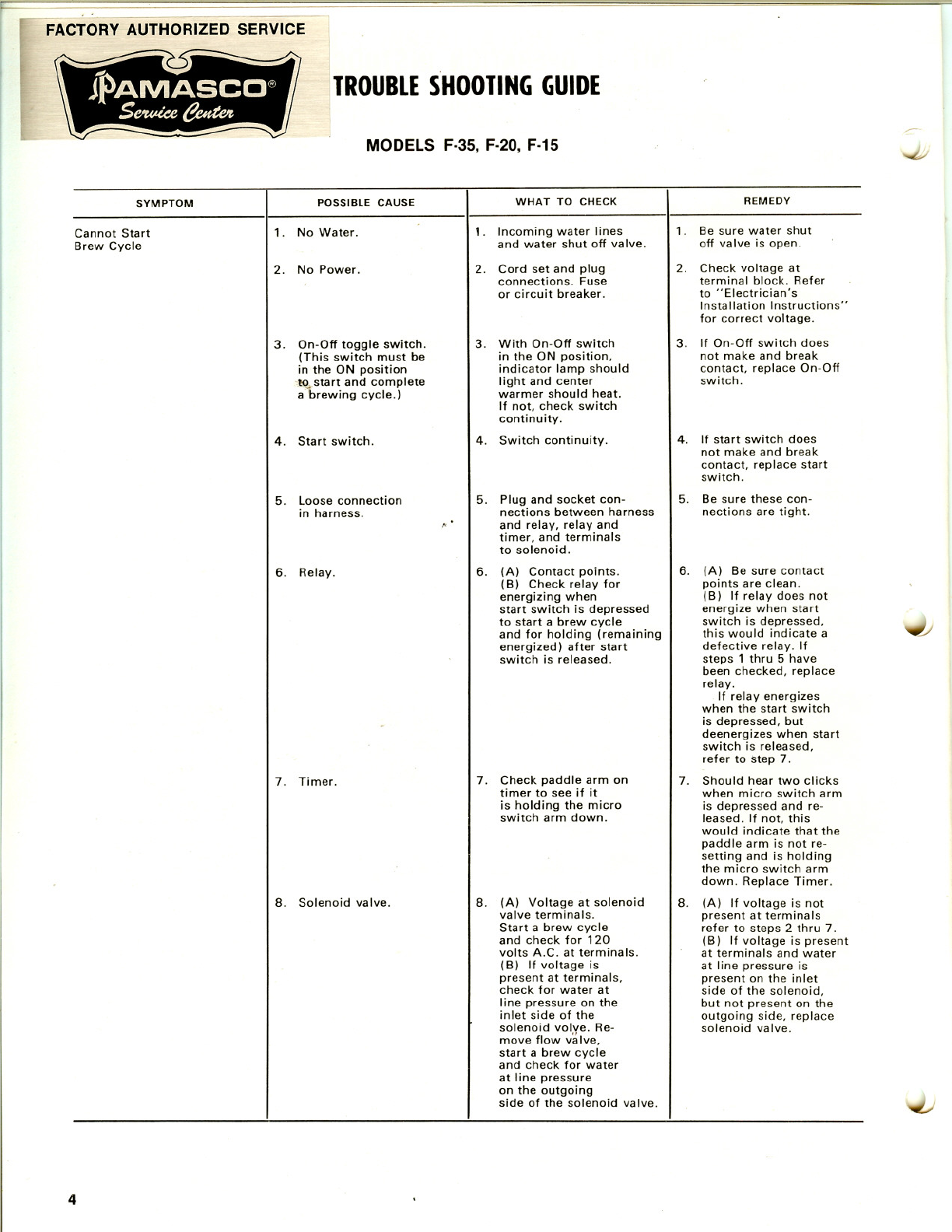

TROUBLE SHOOTING GUIDE

MODELS F·35, F·20, F·15

SYMPTOM

POSSIBLE CAUSE

WHAT TO CHECK

REMEDY

Cannot Start

1.No Water. 1.

Incoming water lines

1.

Be sure water shut

Brew Cycle

and water shut off valve.

off valve is open.

2.

No Power. 2.

Cord set and plug

2.

Check voltage at

connections. Fuse

terminal block. Refer

or circuit breaker.

to "Electrician's

Installation Instructions"

for correct voltage.

3.

On-Off toggle switch.

3.

With On-Off switch

3.If On-Off switch does

(This switch must be

in the ON position,

not make and break

in the ON position

indicator lamp shouldcontact, replace On-Off

·t()_start and complete

light and center

switch.

a brewing cycle.)

warmer should heat.

If not, check switchcontinuity .

4.

Start switch.

4.

Switch continuity.

4.

If start switch does

not make and break

contact, replace start

switch.

5.

Loose connection 5.

Plug and socket con-

5.Be sure these con-

in harness.

nections between harness

nections are tight.

,-

and relay, relay and

timer, and terminals

to solenoid.

6.

Relay.

6.

(A)

Contact points.

6.

(A)

Be sure contact

(B) Check relay for

points are clean.

energizing when

(B)

If relay does not

start switch is depressed

energize when start

to start a brew cycle

switch is depressed,

and for holding (remaining

this would indicate a

energized) after start

defective relay. If

switch is released.

steps 1 thru 5 have

been checked, replacerelay.If relay energizes

when the start switch

-

is depressed, but

deenergizes when start

switch is released,

refer to step 7.

7.

Timer.

7.

Check paddle arm on

7.

Should hear two clicks

timer to see if it

when micro switch arm

is holding the micro

is depressed and re-

switch arm down.

leased. If not, this

would indicate that the

paddle arm is not re-setting and is holding

the micro switch arm

down. Replace Timer.

8.

Solenoid valve.

8.

(A) Voltage at solenoid

8.(A)

If voltage is not

valve terminals.

present at terminals

Start a brew cycle

refer to steps 2 thru 7.

and check for 120

(B) If voltage is present

volts A.C. at terminals.

at terminals and water

(B)

If voltage is

at line pressure is

present at terminals,

present on the inlet

check for water at

side of the solenoid,

line pressure on the

but not present on the

inlet side of the

outgoing side, replace

solenoid volve. Re-

solenoid valve.

move flow valve,

start a brew cycle

and check for water

at line pressureon the outgoing

side of the solenoid valve.

4