22

SERVICE (Cont.)

P1022

Location:

The motor is located inside the hopper assembly.

Test Procedures:

1. Disconnect grinder from the power supply.

2. On Model LPG-2E, disconnect the black wire and

the white wire to the motor from the main wiring

harness, the red wire to the circuit breaker and the

red wire to the Off/On/Start switch. On Model LPG

disconnect the motor wiring harness from the main

wiring harness.

3. Connect the leads of an ohm meter to the red wires

from the motor.

If continuity is present the overload is good.

If continuity is not present the overload will not reset,

replace the motor.

4. Set an ohm meter to read at least 20 ohms. Connect

the leads from the ohm meter to the black wire and

the white from the motor. The ohm reading should

be approximately 18 ohms. Using the bean agitator

slowly rotate the motor shaft in approximately 1/8

turn steps through one full rotation. If ohm readings

are consistent motor windings are good. If readings

vary more than ±1 ohm, replace motor.

NOTE: Clean all grind burrs and mounting surfaces

before reassembly.

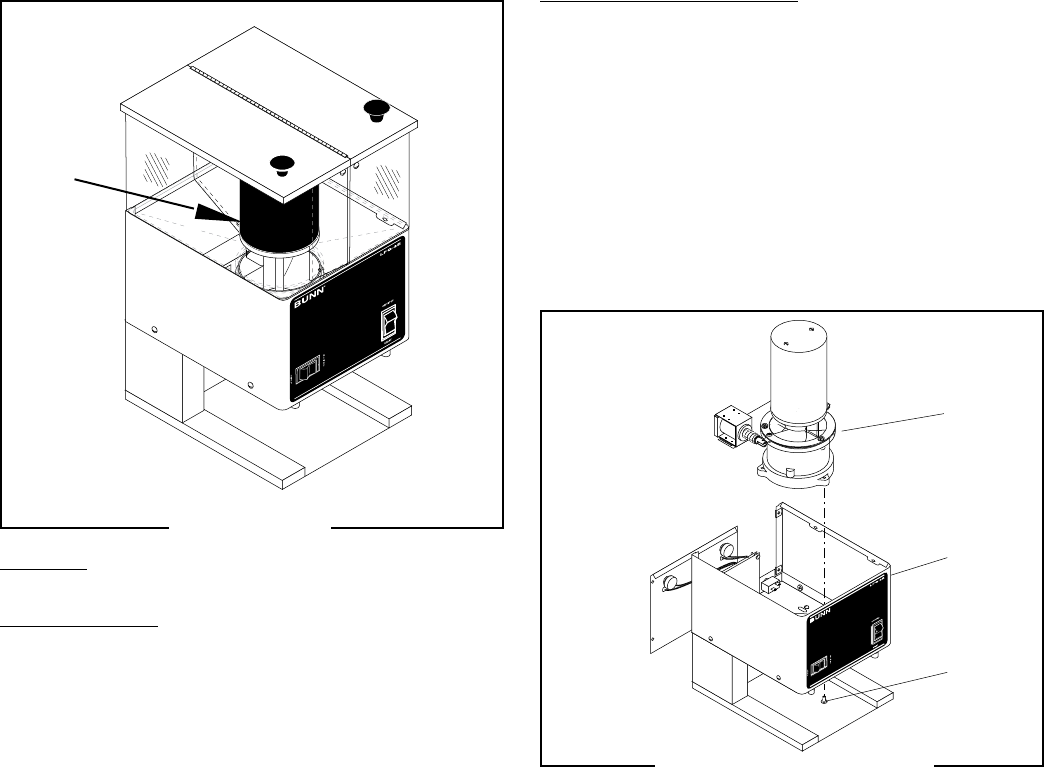

FIG. 9 MOTOR

Removal and Replacement:

1. On Model LPG-2E, disconnect the black wire and

the white wire to the motor from the main wiring

harness, the red wire to the circuit breaker and the

red wire to the Off/On/Start switch. On Model LPG

disconnect the motor wiring harness from the main

wiring harness.

2. On Model LPG-2E, disconnect the red wire from

the left and right solenoid, the orange wire from

the left solenoid and the violet wire from the right

solenoid.

P1049

2

3

1

FIG. 10 MOTOR REMOVAL

3. Refer to Fig 10. Remove the three #10-32 x .25”

screws (1) securing the motor to the motor support

bracket.

4. Remove the motor, solenoid and solenoid com-

ponents (2) from the hopper housing (3) as an

assembly.

NOTE: Steps 5 thru 12 apply only to Model LPG-2E.

5. Refer to Fig.11. Remove the three #8-32 Keps

nuts.

6. Lift the retaining ring w/hopper gasket (1) over the

motor and burr housing assembly (6). Set aside for

reassembly.

7. Lift slide plate, solenoid plunger and spring (2) off

of the dowel pin in the mounting ring and slide

solenoid plunger and spring (2) out of solenoid

coil. Set aside for reassembly. Repeat for opposite

side.

MOTOR (Models LPG & FPG)

41545 122209