Page 6

ELECTRICAL HOOK-UP

CAUTION – Improper electrical installation will damage electronic components.

1. An electrician must provide electrical service.

2. Determine the available on-site electrical service.

3. Select the desired unit voltage based on the available on-site electrical service.

4. Using a voltmeter, check the voltage and color coding of each conductor at the electrical source.

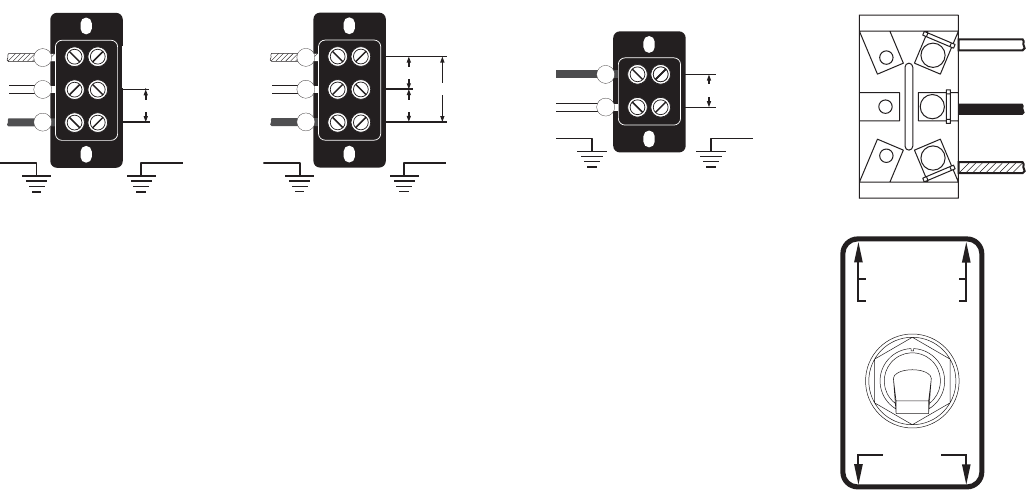

5. Remove the back access panel to gain access to the terminal block.

6. Feed the supply leads through the strain relief at the rear of the brewer.

7. Using the above diagrams, connect the desired electrical service to the fi eld wiring terminal block.

8. If wiring the machine for operation on 120/208 or 120/240 volts with a Power Supply Cord, the Power Supply

Cord must be UL Listed Flexible Cord Type SO, SJO, SJTO, HSJO or SJOW, No. 12 AWG, 4 Conductor, Rated

90° C. Attachment Plug Cap must be UL Listed, NEMA 14-20P or L14-20P Confi guration, Rated 125/250V,

20 AMPS. If wiring the brewer for operation at 200V or 230V with a Power Supply Cord, the Power Supply

Cord must be of type “H07RN-F” with <HAR> marking, 1.5 mm

2

conductor size, rated mimimom 90°C.

Attachment male plug must be appropriate for Local/National use and must meet any Local/National Regula-

tory requirements/certifi cations if applicable. The Power Supply Cord must be at least 3 feet (.91 m) long

and maximum 6 feet (1.82 m) long (measured from Strain Relief to end of the Attachment Plug Cap).

NOTE: If the power cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualifi ed person in order to avoid a hazard.

9. Connect the brewer to the power source and verify th

9. Connect the brewer to the power source and verify the voltage at the terminal block.

10. Set toggle switch on component bracket to the appropriate position and replace the access panel.

11. If plumbing is to be hooked up later be sure the brewer is disconnected from the power source. If plumbing

has been hooked up, the brewer is ready for Initial Set-Up.

36748 101505

WHITE/VIOLET

BLUE

WHITE

BACK

FRONT

120/208V

120/240V

120V

ELECTRICAL REQUIREMENTS

WARNING - The brewer must be disconnected from the power source until specifi ed in Initial Set-Up.

Requirements for brewers without an attached cord set are as follows:

Refer to Data Plate on the Brewer, and local/national electrical codes to determine circuit requirements.

120V AC

single phase models

DUAL VOLT

TOGGLE SWITCH

120/208 & 120/240V AC

single phase models

GREEN GREEN

BLK

RED

120V. A.C.

120V. A.C.

208 or 240V. A.C.

WHI

L1

L2

N

GREEN GREEN

BLK

RED

WHI

L1

L2

N

120V. A.C.

Note: The two electrical services above require 3 current

carring conductors (Neutral, L1 and L2) and a separate

conductor for earth ground

200 or 230V AC

single phase models

Note: This electrical service

consists of 2 current carry-

ing conductors (L1 and L2)

and a separate conductor

for earth ground.

GREEN GREEN

200 or 230V. A.C.

BLK

RED

L1

L2