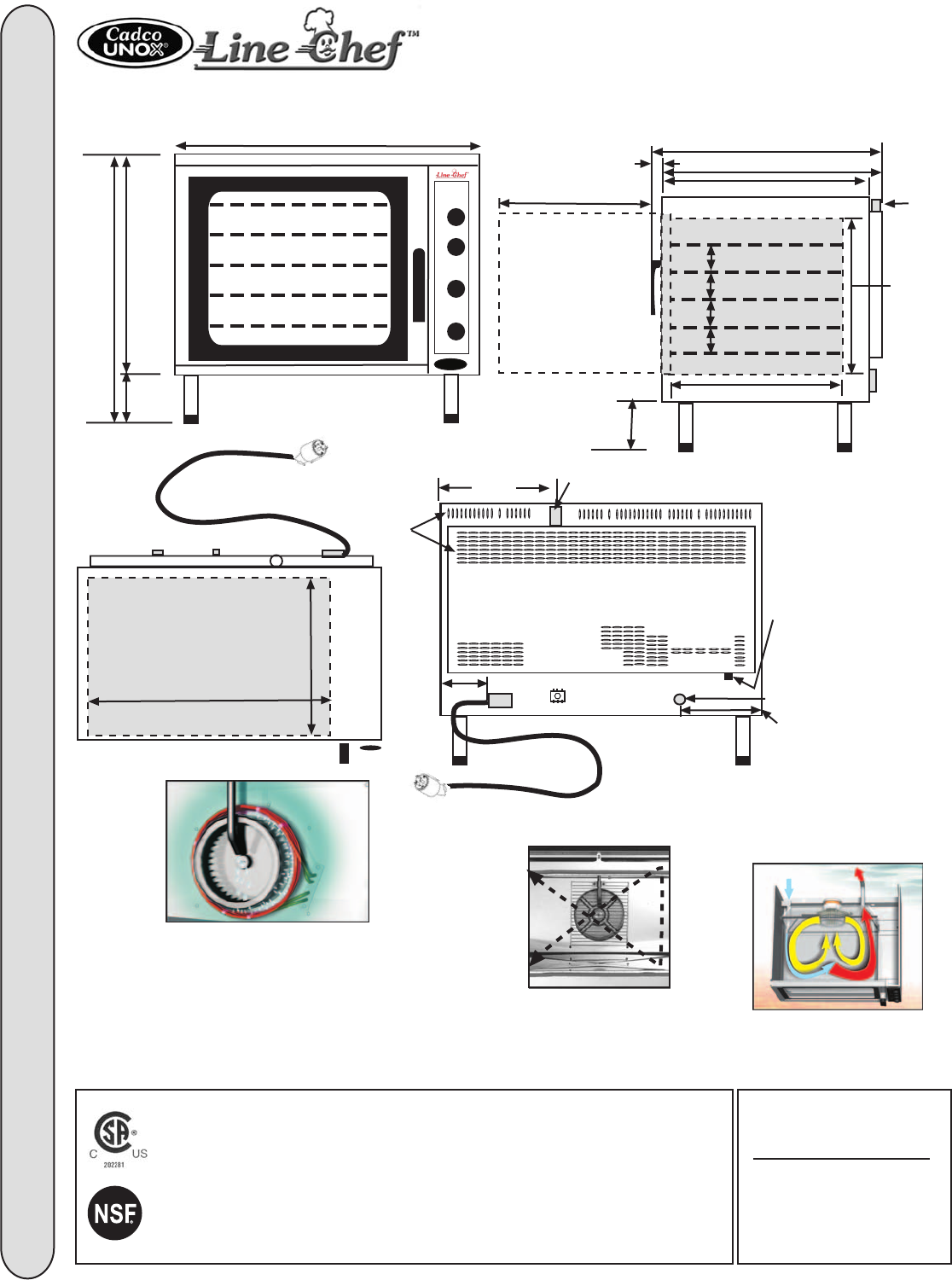

Cross corner

air flow -High speed,

automatic oscillating

reversible fan for even

cavity heating.

Top View

33

4

23

15

(Cooking

Area)

Steam: Water is injected directly into the baking

chamber, vaporized and changed into steam when

touching the hot heating element. Water should be

connected to the oven water inlet by a mechanical

filter and a cut-off valve. Water must have a hardness

between 0.5

o

-5

o

F in order to reduce formation of

limestone deposits inside the electro-valve and inside

the cooking chamber, and a pressure value between

0.5 - 2 bar (7.25 - 29 PSI.)

Cadco, Ltd.

Countertop Coombination Oven - 5 half size sheet pan capacity Model # CAPO-303

Front View

Venturi system - pulls in

cool air and pushes out

damp air, creating a dry

environment.

24-1/4

28-1/4

Side View

4

door open = 27-1/2

15

25-1/2

2-1/2

2-3/4

2-3/4

humidity

vent

(opens

on top)

door closed = 30

(Cooking

Area)

2-3/4

2-3/4

27-1/4

14-1/2

Back View

6

1 diam. water drain

humidity vent = 1diam;

opens on top

106 cord

vents

NEMA L6-30

Plug

11to vent ctr.

14-1/2 to ctr. of water drain

NEMA L6-30

Plug

Combustible Wall

Clearance Required:

Sides: 2

Rear: 4 from back

Top: 3

l CAPO-303 is made to Cadco Ltd. specifications by UNOX S.p.A.

l NSF, UL through CSA Standards

(

Cadco Model CAPO-303 = UNOX Model XAV303)

l CSA File No. 202281-0-000 (UNOX) / covers Classes 2831-83 (US)

and 2831-03 (Canada)

l NSF Listed (UNOX) to ANSI/NSF Standard 4

water inlet - opens

at bottom; handles

NH 3/4 garden

hose fitting

(4-1/4 to ctr. of water inlet)

(NOTE: This page contains the specs for the

individual CAPO-303 oven. The CAPO-3303S

Stacking Kit includes TWO of these ovens, plus

other accessories listed on front page.)