2

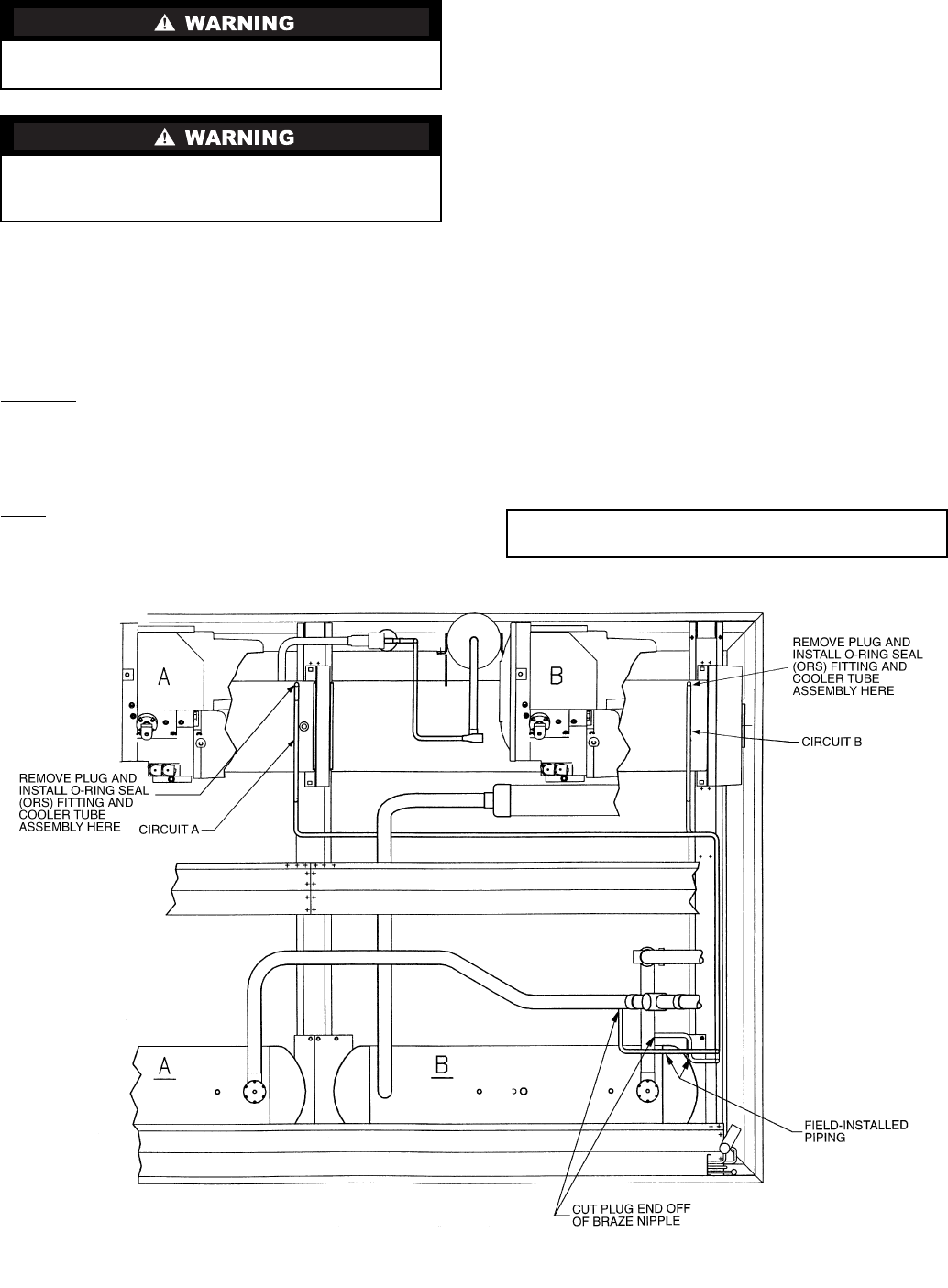

Step 2 — Install Piping

NOTE: The units have 2 circuits. Perform all of the following

piping installation procedures on both A and B circuits.

REMOVE MINIMUM LOAD PORT PLUGS AND IN-

STALL FITTINGS — Plugs must be removed from these

ports and replaced with O-ring seal fittings. Note that plugs

were factory-installed with Loctitet 554 or equivalent

refrigerant-compatible sealant. Fittings should be installed with

similar sealant on threads.

30GXN,R

— Cut plug end off of minimum load port braze

nipple on discharge line, located between oil separator and con-

denser. Remove plug from minimum load port on cooler shell.

See Fig. 1. Using thread sealant, install O-ring seal fitting in

minimum load port on cooler. Port on nipple in discharge line

is reserved for a brazed connection.

30HX

— Remove plugs from minimum load ports on the cool-

er shell and the condenser shell (30HXC) or oil separator

(30HXA). See Fig. 2. Using thread sealant, install O-ring seal

fittings in minimum load ports.

INSTALL PIPING — On 30GXN,R units, carefully thread the

cooler tube assemblies (P/N 30GX503487) on the O-ring seal

fittings installed in the cooler port. Do not tighten. Install field-

supplied

5

/

8

-in. OD copper tubing between the tube assembly

and the brazed nipple on the discharge line.

On 30HX units, carefully thread the cooler tube assemblies

(P/N 30GX503487) and the condenser oil separator tube as-

sembly (P/N 30HX402343) on the O-ring seal fittings installed

in the cooler and condenser/oil separator ports. Do not tighten.

Install field-supplied

5

/

8

-in. OD copper tubing between the

tube assemblies on the cooler shell and condenser (30HXC) or

oil separator (30HXA).

INSTALL BALL AND SOLENOID VALVES — Using good

piping practice, braze ball valve and solenoid valve into

5

/

8

-in.

minimum load piping. Fig. 2 shows a typical 30HX installation

and Fig. 3A and 3B show a typical 30GXN,R installation, in-

cluding valve locations and orientation. Ensure that ball valve

is fully open, and that both the ball and solenoid valve are pro-

tected from excess heat during brazing process. Wrap wet

cloths around valve bodies and tube assembly locking nuts

during brazing to prevent damage to the valves and O-rings

from heat.

CONNECT PIPING — Lubricate O-rings with a light coating

of polyalphaolefin lubricant suitable for R-134a systems.

Thread tube assembly nuts onto the O-ring seal fittings until

they are finger-tight. Lightly snug the nut with a wrench;

DO NOT OVER TIGHTEN. You should be able to feel the O-

ring compress on the last

1

/

4

-turn.

Shut off all power to the unit, then lock out and safety-tag

all disconnects before proceeding with installation.

Remove refrigerant charge from circuits using an ap-

proved refrigerant recovery device before proceeding with

installation.

IMPORTANT: DO NOT over tighten the O-ring seal

nut. Damage will occur to the seal, resulting in leaks.

Fig. 1 — Installing Fittings, 30GXN,R (Typical Size 080-150, 160 Shown)

→

102