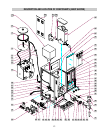

HOPPER COVER CD106

5

AUGER GEAR – FOR RECTANGULAR HOPPERS:

CD117 [Used With Nylon Auger CD130]

CD117 [Used With Wire Auger CD101 &CD130]

FRONT BUSHING:

Rectangular Hoppers:

CD277 [ Ø22.5 mm ]

CD306 [ Ø17 mm ]

Square Hoppers:

CD102 [ Ø2

2.5 mm w/O-Ring CD103]

CD131 [ Ø2

2.5 mm w/O Ring]

AUGERS:

CD130 Nylon Auger [Ø22.

5 mm X 17mm Pitch w/O-Ring CD139]

CD101 Wire Auger [Ø22.5

mm X 17mm Pitch]

Used for Cappuccino Fast Flow & Soup.

PRODUCT GUIDE: CD70A

DISPENSE CAP: [CD61A

White, CD272 Black]

MIXING CHAMBER, FAST FLOW:

[CD137 White, CD275 Black]

Correct Water Level, For Max. Flow Rate, when using

Nylon Auger

[Adjust Water Flow Rate so that the water

level reaches almost to the top in the Mixing Chamber]

Correct Water Level, For Max. Flow Rate, when using

Wire Auger

[Adjust Water Flow Rate so that the water

level reaches Half Way Up in the Mixing Chamber]

DISPENSE NOZZLE: CD67A White

Nut CD136

Turn CW

to unscrew

Triangular

Rib

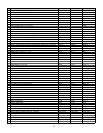

DRINK STRENGTH ADJUSTMENTS

A.

Units With Fixed Speed Auger Motors-AC [CD175]

Fixed Auger Speed [95 RPM] and dispenses powder at a constant fixed rate.

Drink Strength adjustments can be made by adjusting the water flow rate on the Water Dispense Valves. [See section VI]

1. Remove side panel to access the Dispense Valve.

2. Locate Flow Adjustment Screw on Dispense Valve. [See section VI]

3. Rotate adjustment screw Counterclockwise to INCREASE Flow Rate, Clockwise to DECREASE Flow Rate.

(Note: the water flow rate should not exceed 1 to 1.3 oz./sec.)

Do not turn Adjustment Key more than 1/4 turn at a time without checking drink strength (ratio of water to powder).

B. Units With Vari

able Speed Auger Motors-DC [CD151] - (OPTIONAL FEATURE)

Variable Auger Speed [10 to 130 RPM]

Drink or Product Strength adjustments can be made by adjusting the Auger Motor speed.

The Knobs on inside door panel control the amount of product being dispensed [gram throw].

The gram throw is factory preset at 7. Because the consistency of each product varies, the

custo

mer can set the desired gram throw for each hopper.

The water flow rate on the Dispense Valves sh

ould remain fixed.

Note: the water flow rate sh

ould not exceed 1-1.3 oz./sec to avoid spillage from dispense chamber.

[See section VI]