KETTLE VENTING

INSTRUCTIONS

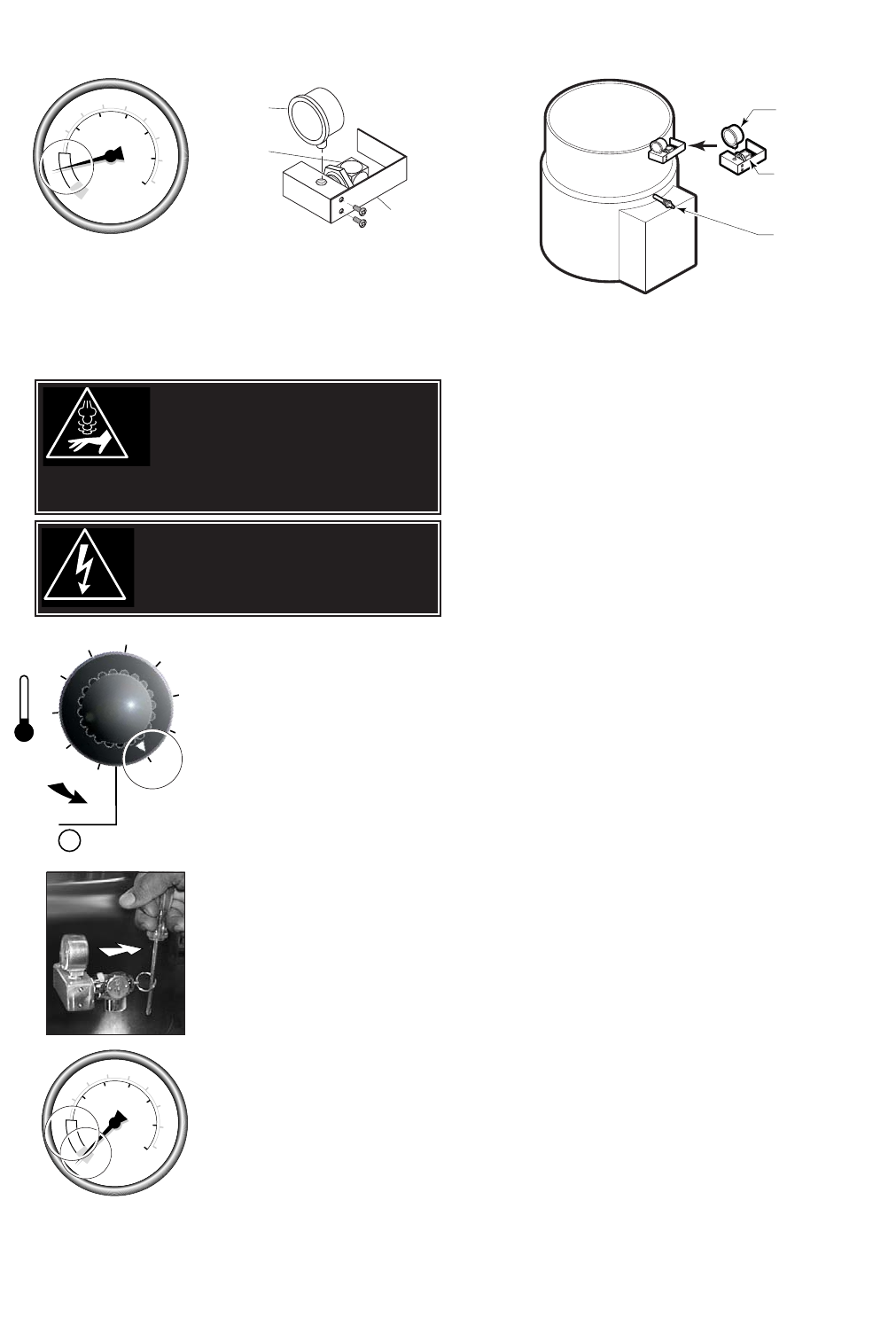

1. Remove guard bracket from

pressure relief valve/gauge

assembly.

2.

Set On-Off Switch/Temperature

Control to to "10" (Max.),

heat the empty kettle until unit

cycles off.

3. Vent kettle by pulling safety

valve ring 8-10 times in short

2-3 second blasts with a 5

second interval between pulls.

NOTE: If unit cycles ON, stop

venting and wait for kettle to

cycle OFF before continuing.

4.

Set On-Off Switch/Temperature

Control to to "0" (Max.). Add

cold water to kettle until its

surface temperature is below

100°F. The pressure gauge

needle should be in the green

zone, indicating a vacuum in

the kettle’s jacket.

5. Replace guard bracket from

pressure relief valve/gauge

assembly.

2

3

5

6

7

8

9

1

4

10

OFF

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R

50

0

100

150

200

250

300

350

400

40

50

60

0

10

20

30

psi

kPa

V

E

N

T

A

I

R

26

Guard

Bracket

Pressure

Gauge

Pressure

Relief

Valve

The following venting procedure

should be followed when the

Vacuum/Pressure Gauge needle

is in the "VENT AIR" zone:

NOTE: Check for and eliminate leaks prior to venting

(See REPAIRING LEAKS IN STEAM JACKETED KETTLE

FITTINGS on page #27).

DANGER: PRESSURE RELIEF

VALVE WILL EXHAUST HIGH

TEMPERATURE STEAM. CONTACT

WITH SKIN COULD RESULT IN

SERIOUS BURNS. KEEP FACE,

HANDS AND BODY CLEAR OF DISCHARGE.

DANGER: WORKING ON MACHINES

WITH POWER COULD RESULT IN

SEVERE ELECTRICAL SHOCK.

VACUUM LEAK TEST

PROCEDURE

If the kettle will not hold vacuum, test for leaks at:

A. Water Level Probe.

B. Pressure Relief Valve.

C. Pressure Gauge.

LEAK TEST PROCEDURE:

1. Heat kettle until unit cycles off.

2. Shut off power to the kettle at the fused disconnect

switch.

3. Spread Bubble Type Leak Detector over suspected

areas and watch closely for bubbles.

4. Repair areas as required.

REPAIRING LEAKS IN STEAM

JACKETED KETTLE FITTINGS

If unit will not hold a vacuum the most likely cause is a

leak at one of the fittings.

Often, the easiest way to eliminate a leak is reseal the

suspect areas.

1. Water Level Probe

Remove,clean threads, apply teflon thread sealant

and reinstall.

2. Pressure Relief Valve

A/ Inspect for signs of leaks. Replace if required.

B/ Remove, clean threads, apply teflon thread

sealant and reinstall.

3. Pressure Gauge

A/ Inspect face of gauge. If it contains moisture

on the inside of face replace.

Pressure

Relief Valve

Pressure

Gauge

Water Level

Probe