Page: 37

UGH020/0301 VL Series Portable Chillers, 0.25 to 1.5 Tons

8.3 WATER QUALITY CONTROL

A. Lack of, as well as, improper water treatment can damage the

chilling unit. The services of a competent water treatment specialist

should be obtained and their recommendations followed. It is the

equipment owner’s responsibility to prevent damage from foreign

material or inadequate water treatment.

B. The two main things to consider for water treatment in chillers are

corrosion and organism growth. Proper chemical treatment can

control PH levels and algae growth. An alternative to chemical

treatment is the addition of 20% inhibited propylene glycol to the

water. This will help prevent organism growth and coat the heat

transfer surfaces with corrosion inhibitor.

8.4 INHIBITED PROPYLENE GLYCOL

A. The use of a water-glycol

mixture is needed when

the operator desires a

process temperature

below 48°F. Freeze

protection is required so

ice crystals do not form

and cause severe damage

to both the water and

refrigeration system.

B. CHOOSING THE PROPER

GLYCOL:

1. For getting the most efficiency from your system, a

propylene glycol such as “DowFrost” is a must. DowFrost

contains special corrosion inhibitors for low system

maintenance and better transfer capabilities than normal

glycols. It also has a much longer fluid life up, to 20 years

in some cases.

2. SOURCES OF INHIBITED PROPYLENE GLYCOLS: for a

complete literature package, material, safety data sheets

and purchasing information, contact the following:

DOW CHEMICAL 1-800-447-4369

(Canada 1-800-363-6250)

Dowfrost inhibited propylene glycol

MONSANTO CHEMICAL 1-800-459-2665

Monsanto FS inhibited propylene glycol

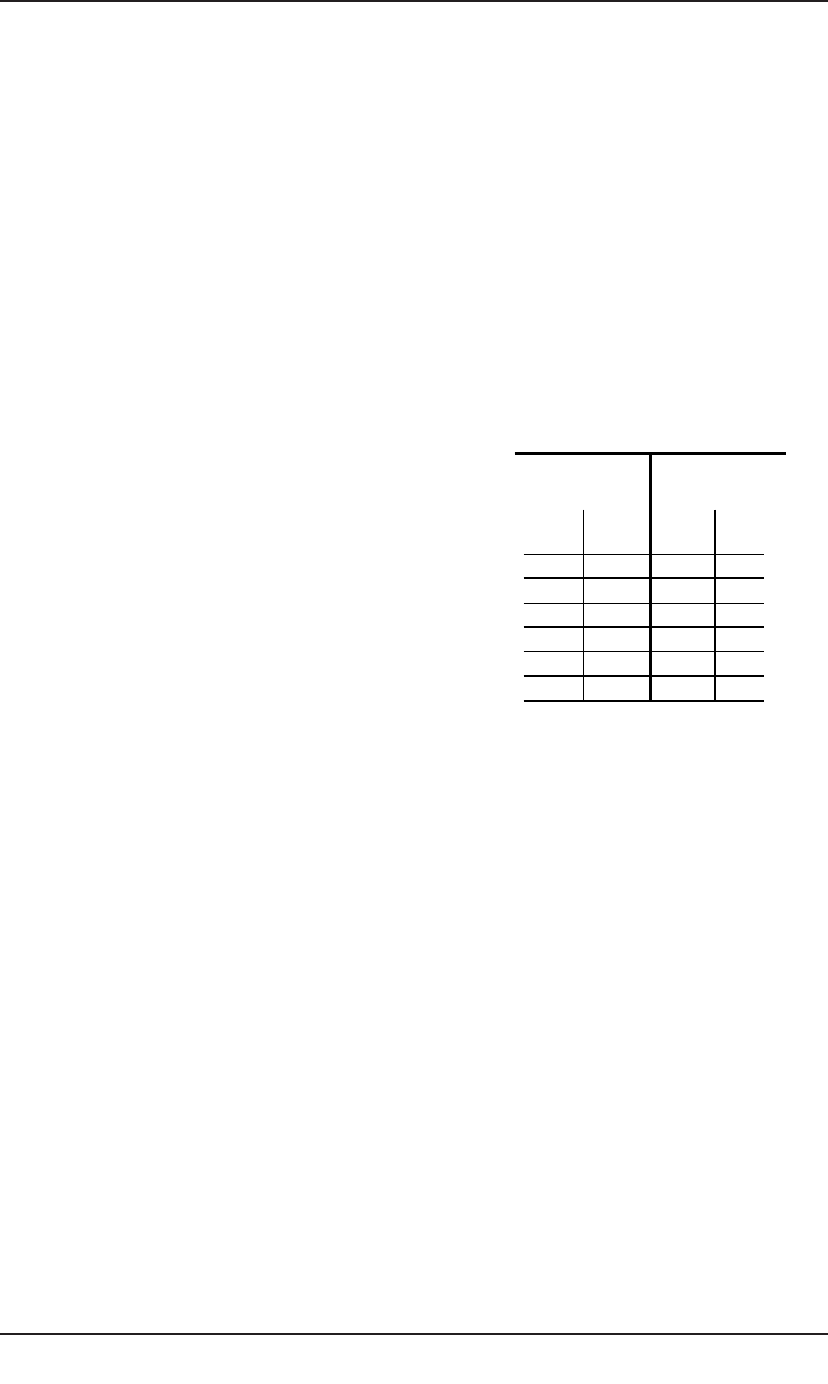

FREEZING POINTS FOR

WATER/PROPYLENE GLYCOL SOLUTIONS

˚F

FREEZE POINT

32

25

10

0

-10

-30

-60

0

-3.9

-12.2

-17.8

-23.3

-34.4

-51.4

˚CWATERGLYCOL*

0

10

20

30

40

50

60

100

90

80

70

60

50

40

PERCENTAGE OF

*PROPLYLENE GLYCOL

NOTE: GLYCOL FREEZE POINT MUST BE 25˚F BELOW

LOWEST SETPOINT