Read these instructions and Operator's Manual in its en-

tirety before you attempt to assemble or operate your new

high pressure washer. Your high pressure washer has, for

the most part, been assembled at the factory, except those

parts left unassembted. Before you can operate your' new

high pressure washer, you must assemble the wheel kit and

properly connect the high pressure hose.

IF YOU HAVE ANY PROBLEMS WITH THE ASSEM-

BLY OF YOUR PRESSURE WASHER, PLEASE

CALL THE PRESSURE WASHER CUSTOMER

HELPLINE AT 1-800-222-3136.

TOOLS REQUIRED FOR ASSEMBLY

• Mallet

• Socket wrench with 1/2-inch or 13ram Sockets

• Crescent Wrenches or Combination Wrenches

• 8ram nut driver

TO REMOVE

CARTON

Q

PRESSURE WASHER FROM

Remove guide handle (wrapped in plastic)o

Remove accessories box from carton_

Remove gun/wand assembly from cardboard holder.

Remove all other packing material from box before

removing your high pressure washer.

HOWTO SET UP YOUR PRESSURE WASHER

TO INSTALL THE WHEEL KIT

Installing wheel kit, requires the tools listed above, the

guide handle and items included in the parts carton. You

can also refer to the Parts Illustration on Page 15.

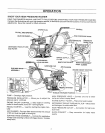

• With the mallet, tap a push nut onto one end of the axle.

Slide a wheel onto the

axle (protruding hub posi-

tionedinward) against the

push nut (Fig. 1), then add

a spacer',

Slip this assembly

through hote at the base

of the pressure washer

and attach the wheel

_pacer, wheel (protruding

ub positioned inwara)

and push nut on the other

end of the axle. Tap the

second push nut with mal-

let until secure (Fig. 2)

SPACER

AXLE PUSH NUT

FIG. 1

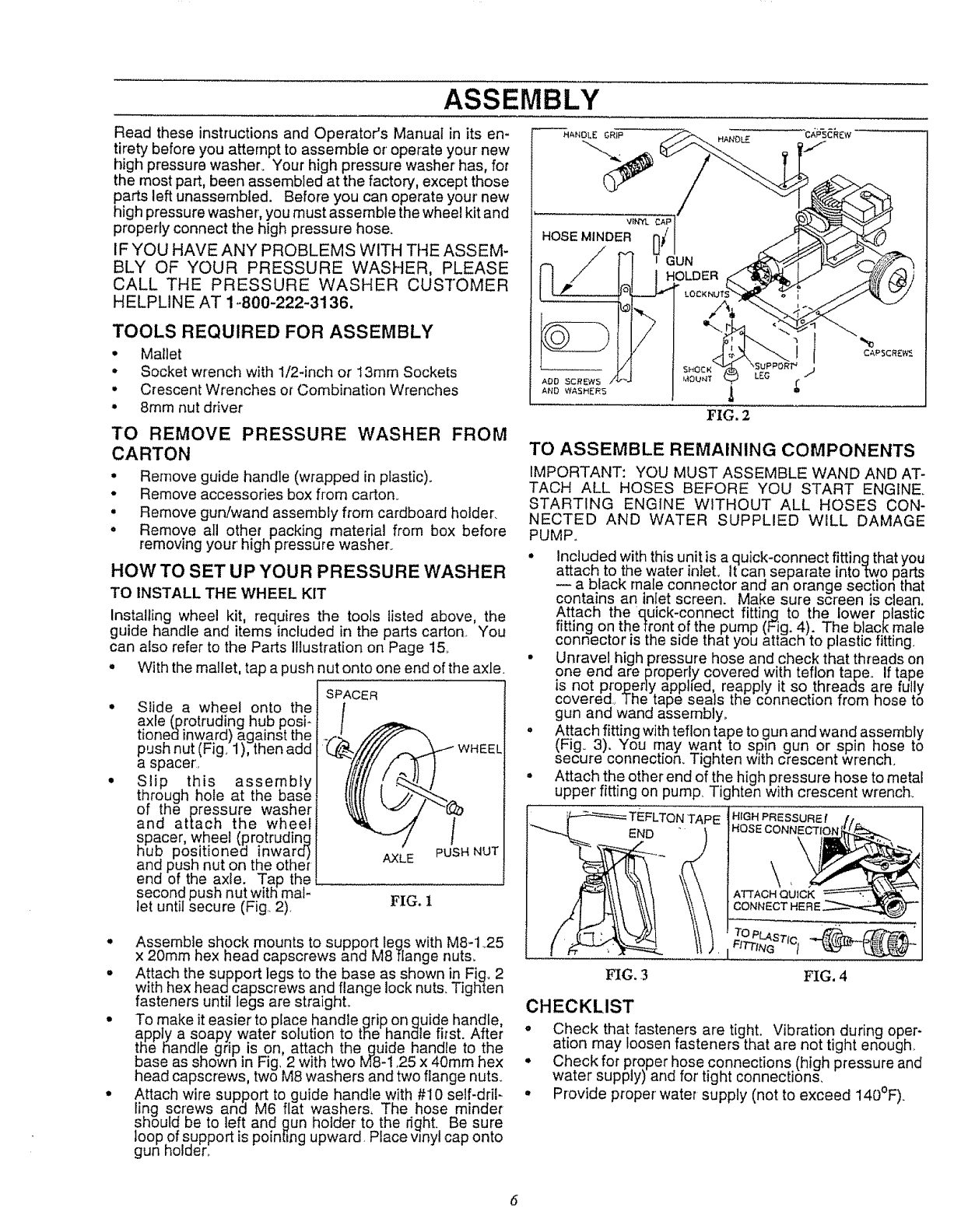

• Assemble shock mounts to support legs with M8-1 25

x 20mm hex head capscrews and M8flange nuts.

• Attach the support legs to the base as shown in Fig, 2

with hex head capscrews and flange lock nuts. Tighten

fasteners until legs are straight.

• To make it easier' to place handle grip. on guide handle,

appJy a soapy water solution to the handle first. Af!er

!he handle grip is on attach the guide handle to the

Dose as shown in Fig, 2 with two M8-1,25 x 40mm hex

head capscrews, two M8 washers and two flange nuts.

• Attach wire support to guide handle with #I0 self-dril-

ling screws and M6 flat washers. The hose minder

should be to left and gun holder to the right. Be sure

loop of support is pointing upward Place wnyt cap onto

gun holder,.

TO ASSEMBLE REMAINING COMPONENTS

IMPORTANT: YOU MUST ASSEMBLE WAND AND AT-

TACH ALL HOSES BEFORE YOU START ENGINE.

STARTING ENGINE WITHOUT ALL HOSES CON-

NECTED AND WATER SUPPLIED WILL DAMAGE

PUMP.

• Included withthis unit is a quick-connect fitting that you

attach to the water inlet, It can separate into two parts

a black male connector and an orange section that

contains an inlet screen. Make sure screen is clean.

Attach the quick-connect fitting to the lower plastic

fitting on the front of the pump (Fig. 4). The black male

connector is the side that you attach to plastic fitting

• Unravel high pressure hose and check that threads on

one end are properly covered with teflon tape. If tape

is not proper],/apphed, reapply it so threads are fully

covered, The tape seals the connection from hose to

gun and wand assembly_

• Attach fitting with teflon tape togun and wand assembly

(Fig. 3). You may want to sp)n gun or spin hose to

secure connection. Tighten with crescent wrench.

• Attach the other end of the high pressure hose to metal

upper' fitting on pump. Tighten with crescent wrench.

END

FIG. ,3

rAPE

TO PLASTrc,

FITTING t

FIG. 4

CHECKLIST

o Check that fasteners are tight. Vibration during oper-

ation may loosen fasteners that are not tight enough_

• Checkfor proper hose connections (high pressure and

water supply) and for tight connections,

• Provide proper' water supply (not to exceed 140°F).

6