9. FLUE ARRANGEMENT

Flue Baffle

The flue baffle (4, fig. 10) must be in position in the central tube

of the boiler, suspended on its support wire so that the lower end

of the baffle is 75 mm (3") above the bottom of the central tube

over the burner. The top end of the baffle support wire is bent into

the shape of an "O" and rests horizontally on the tp of the central

tube. The baffle is correctly positioned during the manufacture

ans should not become displaced during normal use. If the flue

baffle is missins or is incorrectly located, the cooling unit will not

operate properly on gas. Any strapping tape used to retain the

baffle support wire to the top of the boiler casing during transit

should be removed before installation.

Flue Venting Kit

The flue gasses must be vented directly to the outside air. Only

the flue venting kit (supplied with the refrigerator in the United

Kingdom) is recommended for this purpose. It consists of the

following parts:

Flue Top Complete-G

Flue Outlet Cover Plate-B

Exhaust Gas Pipe Complete-F

Screw-sELF tAPPING. nO. 6 X 1/4in-H

The flue top (G) is in the form of a lazy "T" and incorporates an

air-break to minimise the possibility of flame extinction due to

draughts.

Leading from the flue-top, the extension tube (F) has to pass

through the wall of the vehicle to direct the flue gasses to the

outside. Care must be taken in determining the positions of the

centres of the holes in the inner and outer skins of the caravan

wall to accept the extension tube. As the amount of space

between the back of the refrigerator and the inside wall og the

vehicle as well as the thickness of the wall, may vary for each

type of caravan, it is not possible to give actual dimensions

therefore each case must be considered carefully before starting

to make the opening. Take particular care to ensure that the angle

is correct so that when in position, the extension tube will line up

accurately with the sloping part of the flue-top.

The opening mus be large enough to allow the insertion of a layer

of non-combustible material around the extension tube as shown

in fig. 7, but the opening in the outer skin must not exceed 70 mm

(2 3/4") in diameter, otherwise the flange on the flue outlet may

not cover it completely.

4

Alternatively, wooden battens may be screwed to the sides of the

recess, from front to back, bearing down on the top of the cabinet to

hold it firmly, as shown at A, fig. 4. Whichever method is used, it must

be possible to remove the refrigerator easily for subsequent servicing

purposes. The brackets or battens must be in a position where they

will not restrict the air circulation over the cooling unit; they must not

be positioned across the cabinet over the fins of the condenser of the

cooling unit at the rear, otherwise air-flow will be impaired and

performance affected.

Fitting the Upper Ventilator

To fit the upper ventilator, screw a block of wood approx. 25 mm (1")

square x 66 mm (2 5/8) long. to each side of the recess, 16 mm (5/8")

back from the front edge, as shown at B, fig. 4. Secure the ventilator

to the blocks with a screw through the hole provided at each end.

Additionnal Ventilator

To reduce the amount of heat entering the caravan, particularly when

used in warner climates, an additionnal ventilator (A, fig. 5), may be

fitted in the wall of the vehicle, preferably above the level of the top

of the refrigerator. (The exterior flue venting kit must still be used).

All surfaces above and adjacent to the flue outlet, and beside and

below the burner housing should be of, or protected by, metal or

other inflammable material.

8. VENT HOLE UNDER REFRIGERATOR

A ventilation hole of not less than 13 cm2 (2in2) effective area (40

mm or 1 5/8" diameter) must be provided in the floor below the

refrigerator as shown in fig. 5. The hole should lead directly to the

outside air through the floor or wall so that, in the event of a gas leak,

it would provide an escape outlet for the heavier-than air gas. It

should not be too close to the burner where draught could affect the

flame.

On mobile installations, the vent hole should be shielded against

entry of mud etc., by a deflector as shown in fig. 5a, fitted underneath

with its "closed" end facing the front of the vehicle. The deflector

should be made from a suitable piece of metal, to suit the particular

installation.

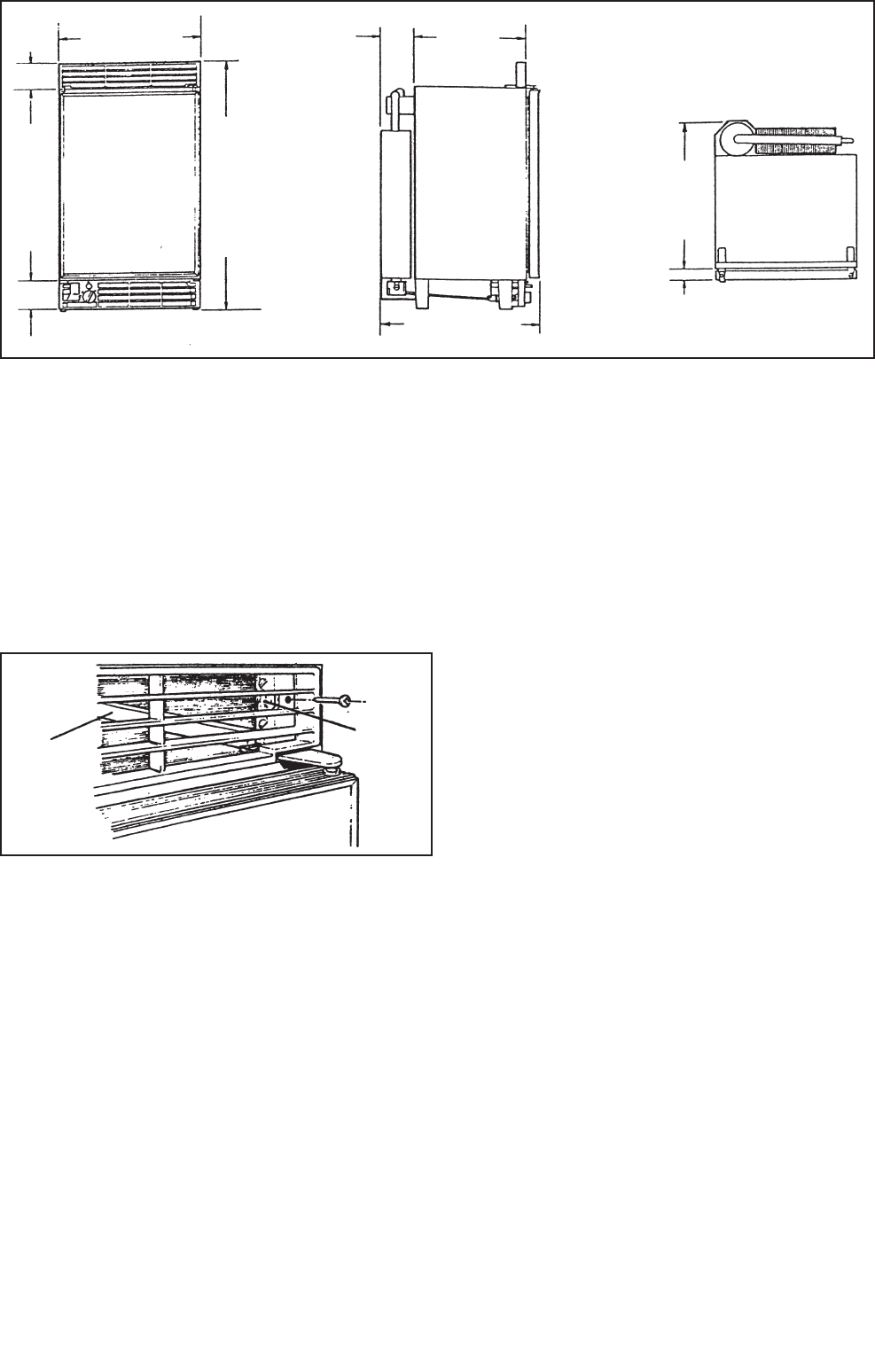

Fig. 3

Fig. 4

73 mm

(2

7

/

8

")

100 mm

(4")

300 mm

(11

13

/

16

")

39 mm

( 1

1

/

2

")

380 mm (15")

439 mm (17

5

/

16

")

510 mm (20

1

/

16

")

659 mm (25

15

/

16

")

400 mm

(15

13

/

16

")

A

B