Electrolux air-o-chill

Blast Chiller/Freezers 30-25kg

Internet: http://www.electrolux.com/foodservice

HDBB0102010-05-10Võib muutuda ilma etteteatamata

TORN TÄITE TUGI 6GNAHJULE+30KG KJ/KK 881011

LW+CW KIIRJAH.KIIRKÜLMIKU HACCP LIIDES 880183 880183

KOM. 5RVT SIINI-6&10GN1/1 KIIRJA/KÜLM.LW 880087 880087

KOLME SONDI KOMPL.KIIRJAH.KIIRKÜLMIKULE 880269 880269

KIIRJAH.KIIRKÜLMIKU RATTAKOMPL(4) 880111

KAETUD VÕRGU RIIULITUGI 881061 881061

JAHUTI JA K/KÜLMIKU 2 SENSORSONDI 880096 880096

JAHUTI JA K/KÜLMIKU 1 SENSORSOND 880089 880089

HACCP BAASVERSIOONI PRINTER 881532 881532

EKIS HACCP KOMPLEKT 922166 922166

AHJUTOGI+RATTAD 6X1/1GN, 65MM 922005 922005

AHJUTOGI+RATTAD 5X1/1GN, 80MM 922008 922008

1/1 GN AISI 304 RVT RESTIPAAR 921101 921101

(ILMA TORNITA) PIND 726619KJ+KK726656 880027

LISAVARUSTUS

TORN TÄITE TUGI 6GNAHJULE+30KG KJ/KK 1

KOM. 5RVT SIINI-6&10GN1/1 KIIRJA/KÜLM.LW 1 1

JAHUTI JA K/KÜLMIKU 3 SENSORSONDI 1 1

STANDARD LISAVARUSTUS

Netokaal - kg 169 165

paigaldatuna-elekter 1.937 1.937

Võimsus - kW

Aurustustemperatuur - °C -30 -30

Jahutusaine võimsus - W 1600 1600

Jahutusaine kogus - g 2830 2830

Jahutusaine tüüp R404a R404a

Kompressori võimsus - hp 1.8 1.8

Asendite arv/siinide vahe mm 18, 20 18, 20

Maks. mahutavus nõu kõrgus 65 mm 6 6

Kandikute tüüp 600x400; GN 1/1; Ice

Cream

600x400; GN 1/1; Ice

Cream

Ukse hinged Parem pool Parem pool

Välismõõtmed -mm/kõrgus 1060 1020

sügavus/avatud ustega 1007, 1378.5 1007, 1378.5

Välismõõtmed -mm

Välismõõtmed -mm/laius 897 896

Termomeetrid Digitaalne Digitaalne

Termostaat Elektrooniline Elektrooniline

Kontrolli tüüp Elektrooniline Elektrooniline

Jahutusseade Sisseehitatud Sisseehitatud

UK standrad 30, 25 30, 25

Tootlikkus tsüklis - kg.

Jõudlus tsüklis - kg/NF. regulatsiooni alusel 18, 18 18, 18

Tüüp E - KÜLMUTID - 30 KG E - KÜLMUTID - 30 KG

TEHNILISED ANDMED

AOFPS061C

726346

AOFPS061CT

726347

PERFORMANCE

• Blast Chilling cycle: 30 kg from

+90°C up to + 3°C in less than 90

minutes.

• Blast Freezing cycle : 25 kg from

90ºC up to -18 ºC in less than four

hours.

• Multi-purpose internal structure is

suitable for 6 grids GN 1/1 (18

positions available with 20 mm pitch)

6 grids or trays 600 x 400 mm (18

positions availabe with 20 mm pitch)

or 9 ice-cream basins of 5 kg each (h

125 x 165 x 360).

• Chilling and freezing times can vary

according to food quantity, density,

moisture contents and type of

containers. Chilling capacity

according to NF* regulations is 18 kg.

CONSTRUCTION

• Internal and external finishing in 304

AISI stainless steel and pack panel in

galvanized steel.

• High density polyurethane

insulation, 60 mm thickness, HCFC

free.

• Environmentally friendly: R404a as

refrigerant fluid.

• Developed and produced in ISO

9001 and ISO 14001 certified factory.

• Inner cell with fully rounded corners.

• Door equipped with removable

magnetic gasket with hygienic design.

• All motors and fan waterproof

protected IP20.

• Evaporator with anti rust protection.

• Ventilator (fan) swinging hinged

panel for access to the evaporator for

cleaning.

• Automatic heated door frame.

• Hot gas defrosting system.

• Solenoid valves.

• 1 thermostatic expansion valve.

• Feet 150 mm high.

• Stand alone printer as optional, built

in on request.

• PC connection on request, gate RS

485.

INSTALLATION

• No water connections required.

• Waste can be plumbed into drain,

but can also be collected in optional

waste container.

*NF HYGIENE ALIMENTAIRE

certifying authority : AFAQ AFNOR

CERTIFICATION. Adress:11, Avenue

Francis de Pressense - 93571

Saint-Denis La Plaine Cedex - France.

Conformity with regulation NF031.

Certified guarantees: fitness for

cleaning, thermal performance

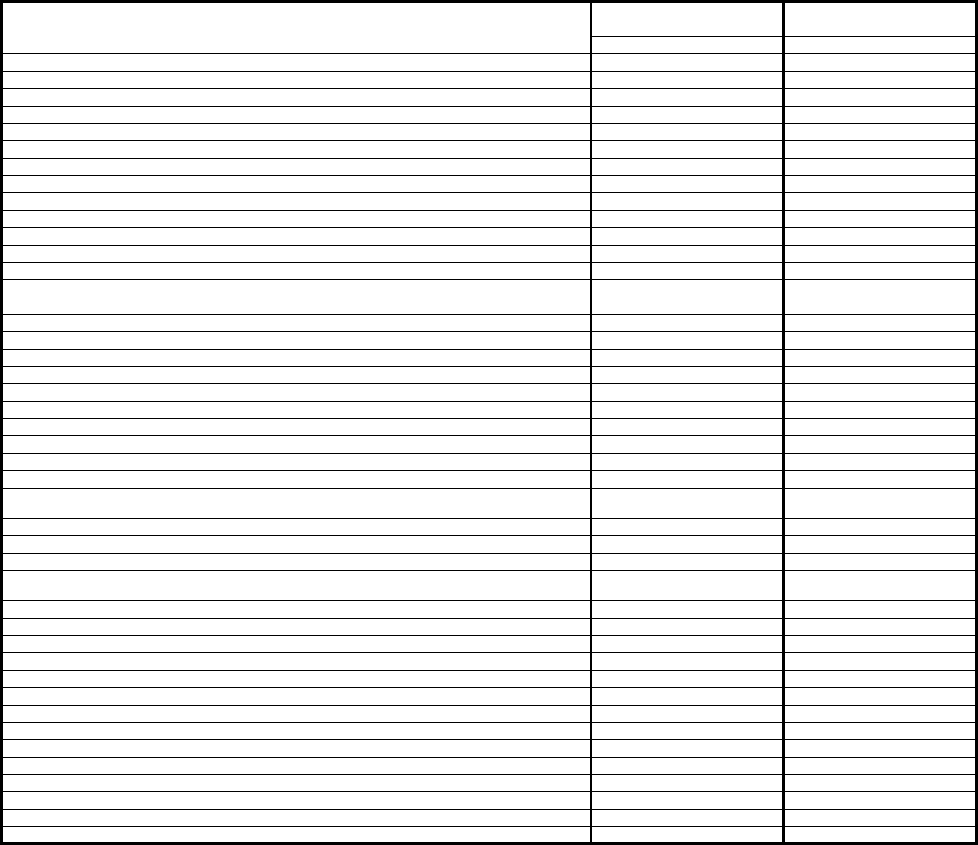

Installation diagram:

D - Drain

EQ - Equipotential screw

TCA - Technical connection area

EH - HACCP