OPERATING INSTRUCTIONS

Page 8 62.9694.01

• Clean insert and seals (D).

• Clean the inside surfaces and the pipe to the pan with a

bottle brush.

• Grease the insert (E) lightly with tap grease.

• Tap grease can be purchased commercially. Damaged

seals must be replaced.Installing the insert.

• Pull the bolt (B) out and -simultaneously push insert (E)

down into the housing

5. WORKING RULES

Pay attention to the sensitivity of the temperature control sys-

tem when placing food on the bottom plate of the braising pan.

The heat will remain evenly distributed if the load-ing of the

pan is started in the middle of the front half of its plate. This

same zone should also be used when roasting small portions

of food.

Loading the pan

The pan has a level indicator on its rear side. The maximum

loading mark is situated about 1.6 inch (4 cm) below the pour-

ing level of the spout. When being loaded with liquid sub-

stances in the horizontal position, the pan must be filled up to

this maximum loading mark only.

For the "Cook" function (temperature setting up to 212°F

(100°C)) to operate correctly, the pan must be filled with food

to a depth of at least 1.2 - 1.6 inch (3 - 4 cm) to prevent the

food from being burnt. The SOFT function should be activated

if the pan is filled with less food.

Sticky food

To prevent the food from sticking to the bottom of the pan, the

following procedure can be applied:

Mix about 2 kg of unpeeled, uncleaned slices of potatoes with

about 2 kg of salt and spread out this mixture on the empty

cold bottom of the pan. Afterwards, heat up the pan gradually

to the maximum heat during one hour. Then let it slowly cool,

without quenching it with water.

6. CLEANING

Before being cleaned, the appliance must be switched off and

allowed to cool.

Pan with a polished steel bottom

Do not use water for cleaning. This would cause the food to

stick to the pan, which in turn would necessitate a treatment as

described in chapter 8. Clean the pan by rubbing it with a dry

cloth or with absorptive paper.

Pan with a chrome nickel steel plated bottom

In general it suffices to clean the pan with hot water, a stand-

ard grease solvent, and a brush. Afterwards, rinse the pan with

hot water and rub it dry with a cloth or ab-sorptive paper.

Cover, lid and panels

The cover, lid and panels are made of stainless chrome nickel

steel. Clean them with hot soapy water and a stan-dard grease

solvent and rub them dry.

In general

Do not clean the appliance with steel brushes, steel wool, cop-

per cloths, abrasive products, etc., as these would destroy the

metal surfaces and thus facilitate corrosion.

The appliance must not be cleaned with high pressure clean-

ers or water jets, owing to the danger of malfunc-tions.

7. TROUBLESHOOTING

Faults in the appliance are registered by the control electronics

and shown on the display (AT) dependent on the type of fault

by the letters A or E in combination with a double-digit number.

When the fault occurs, an intermittent acoustic signal sounds,

the power supply is interrupted and the lamp is switched off.

Press button (Q) again to acknowledge the error message

(acoustic signal).

Shut down the appliance if a continuous fault that prevents

operation arises (see section 5.5 Shutting down). Summon the

aftersales service to remedy the fault. Until this is done, the

appliance must not be used and must be disconnected from

the mains supply.

8. TREATMENT OF COMMERCIAL KITCHEN

APPLIANCES

Commercial kitchen appliances are executed in corrosion

resistant chrome nickel steels, material numbers 1.4301 and

1.4404.

The corrosion resistance of these steels is based on a passive

layer formed on the surface with access to atmospheric oxy-

gen. Accelerated formation or reformation of the passivity

occurs by treating surfaces with running water containing oxy-

gen. Aggressive media with a reducing effect (oxygen con-

suming) such as substances containing hydrochloric acid,

chlorides and seasoning concentrates, mustard, vinegar

essence, seasoning or spice tablets, salt solutions, etc.,

depending on concentration and temperature, can result in

chemical damage or the destruction of the passive layer. Dam-

age can also result from foreign rust (iron particles) due to the

formation of galvanic elements and lack of oxygen (no air

access or low oxygen water).

Therefore the following principles should be observed when

working with high grade steel equipment:

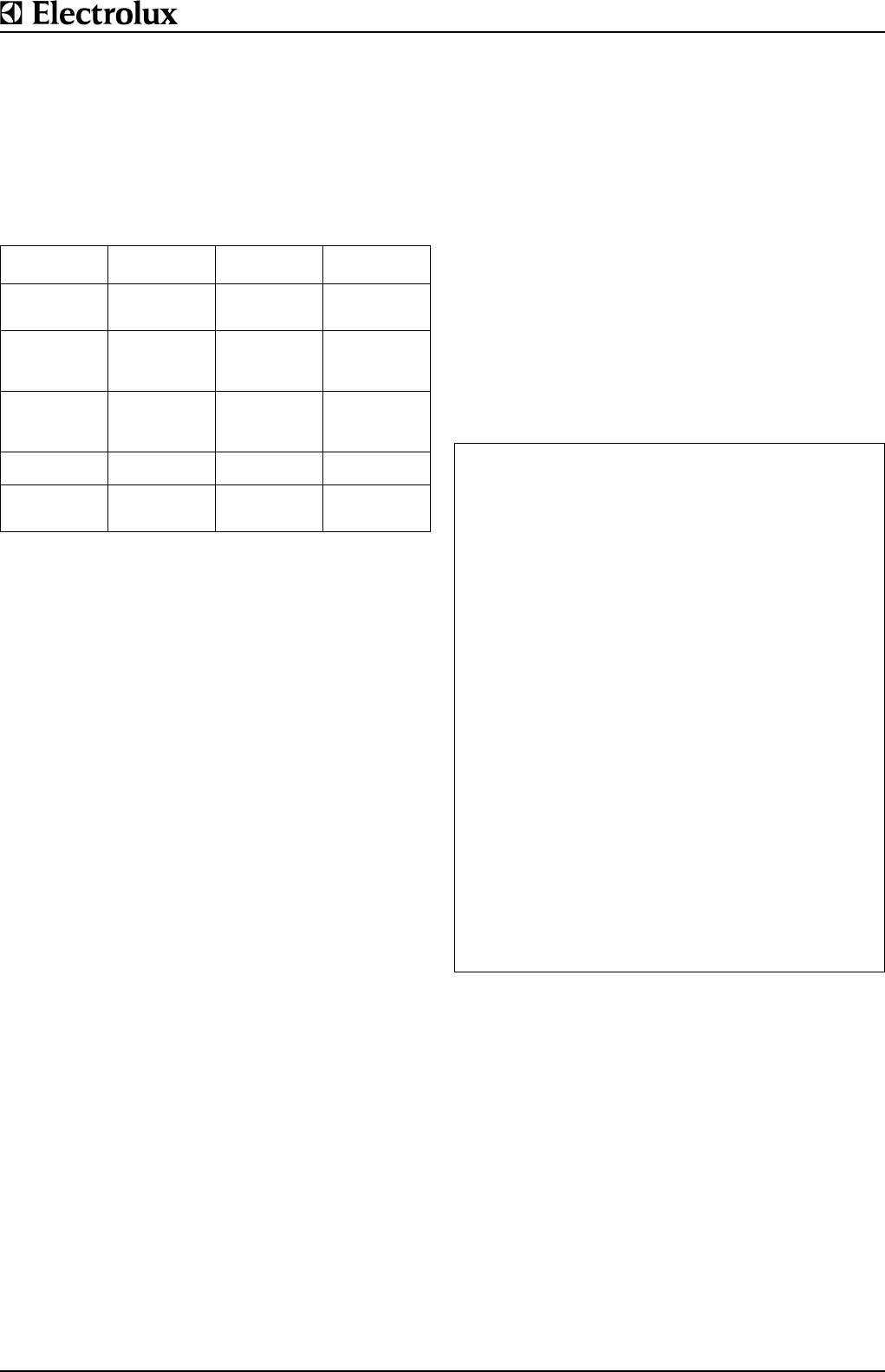

Cooking

process

Food Temperature Comments

Sautéing, brief roast-

ing

Escalope, steaks,

diced meat, shred-

ded meat

374°F (190°C) Cover opened

Roasting Pieces of meat initially 391°F

(200,°C)

then 230-320°F (110-

160°C)

Cover opened

Stewing, braising White meat, poultry initial roasting 392°F

(200°C)

glazing 392°F

(200°C)

Cover opened

Cover closed

Steaming, glazing Vegetables 284-320°F (140-

160°C)

Cover closed

Poaching, light

browning

Poultry initially (284-320°F

(140-160°C)

then 176°F (80°C)

Cover closed

E1

Failure of produce temper-

ature sensor

Summon service agent

and report reading

E2

Failure of bottom tempera-

ture sensor

Summon service agent

and report reading

E5

Failure of control circuit

board temperature sensor

Summon service agent

and report reading

E6

Sensor J15 of produce

temperature is too high

Summon service agent

and report reading

E7

Sensor J16 of bottom tem-

perature is too high

Summon service agent

and report reading

E9

Failure of analogue/digital

converter

Summon service agent

and report reading

E10

Safety thermostat for dry

cycle protection has

responded

Summon service agent

and report reading

E21

HACCP Master Personal

Computer is not con-

nected.

Discharge fault display

and signal by pressing but-

ton (Q).

E22

HACCP Interface

COP485.1 is not con-

nected.

Discharge fault display

and signal by pressing but-

ton (Q).

E23

HACCP configuration;

EEPROM COP485.1

(memory chip) has found a

reeding fault.

Discharge fault display

and signal by pressing but-

ton (Q) and repair fault.

E24

HACCP configuration;

EEPROM COP485.1

(memory chip) has found a

spelling fault.

Discharge fault display

and signal by pressing but-

ton (Q) and repair fault.