4A.3 Temperature Setpoint for Chiller

The temperature setpoint for the chiller should be set by turning the potentiometer. To obtain an

accurate setpoint, connect a voltmeter (millivolt) to TP1 and TP2. The readout will display tem-

perature in degrees Fahrenheit. Turn the potentiometer to the desired setpoint.

A “well” sensor is factory-piped and wired to accurately measure the temperature of the water

leaving the chiller. This sensor provides input to the Electronic Hot Gas Bypass Controller. The

sensor changes electrical resistance in response to temperature changes. To check or troubleshoot

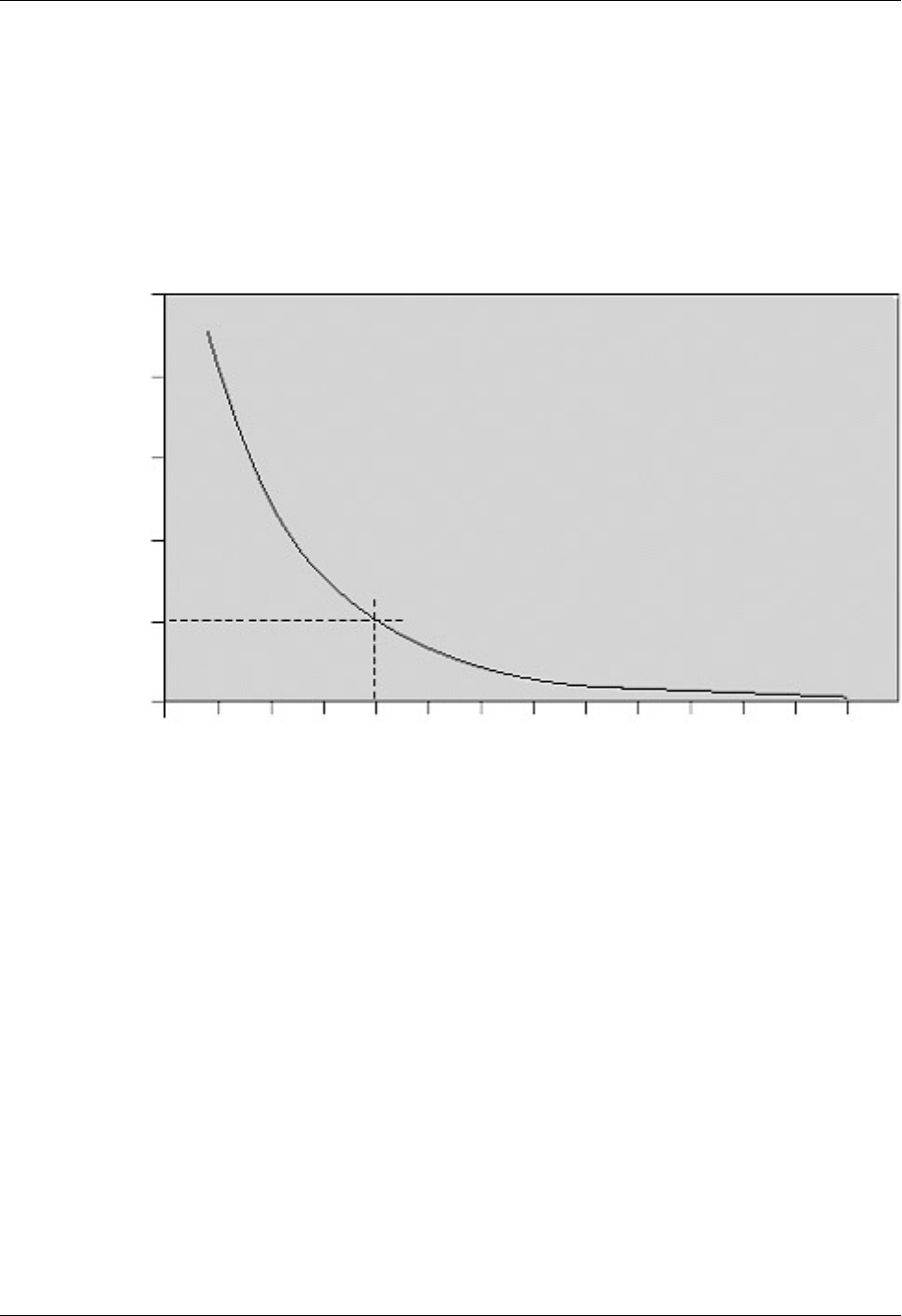

the sensor, disconnect it from the controller and measure the resistance. Figure 3E shows the

relationship between temperature and resistance.

Figure 3E Temperature sensor resistance

4A.4 Flow Control

A circuit setter is factory-installed in the supply line and a ball valve is factory-installed in a

bypass loop. The desired system flow to the load should be set by adjusting the circuit setter to the

required flow rate. If a flow rate of less than 5 gpm is required, the ball valve should be adjusted

to keep the overall system flow rate up. If low suction pressures are present, the circuit setter

should be set to a higher flow, with the bypass valve used to control flow to the load.

TEMPERATURE (Degrees Fahrenheit)

OHMS

20,000

30,000

50,000

-60

10,000

40,000

-40 -20 0 604020 80 100 120 140 160 180 200

Maintenance 18E