7

2009 Foodservice Catalog

MRS ENVI-RO 600

2009 Foodservice Catalog

MRS ENVI-RO 600

6

MRS ENVI-RO™ 600 High Efficiency Reverse Osmosis System

Need RO water, but feeling guilty about the “non-green” waste-to-drain aspect? The high output/high

efficiency MRS E

NVI-RO 600 configurable system turns the tables on conventional reverse osmosis

operation — more water is produced, less goes down the drain.

The MRS E

NVI-RO 600 incorporates a dual-head pump and recovery management system, thus

reversing the proportion of waste-to-RO water and significantly increasing the system’s efficiency and

decreasing total w

ater requirements. What’s more, the MRS E

NVI-RO 600 delivers reverse osmosis and

blended (reduced dissolved mineral) filtered water for multiple foodservice applications.

The presence of undesirable or excessive concentrations of dissolved minerals in many water supplies

effect a foodservice operation in several ways…

Food and beverages taste or appear different

Equipment scales-up and does not function correctly, or over time fails to function at all

Equipment for reducing dissolved mineral concentrations varies, but some of the more common

technologies they employ include Reverse Osmosis, Ion Exchange and Distillation.

Reverse Osmosis has become the most preferred method for Foodservice operations. It consumes

little or no electricity and does not require dangerous chemicals. One drawback to traditional RO

systems is the amount of water that is sent to drain when the unit operates.The term for this is

recovery, and is normally expressed in a percentage or as a ratio.

Conventional RO Systems

By contrast,conventional RO systems (20% recovery)

send four volumes of water to the drain for each volume

of coffee produced.

Wastewater to Drain

MRS E

NVI

-RO 600 Systems

With an average recovery of 78%,the MRS ENVI-RO

600 system only disposes ~1/4 of a cup of water for

each cup of coffee brewed

Wastewater to Drain

Water’s Impact On Foodservice

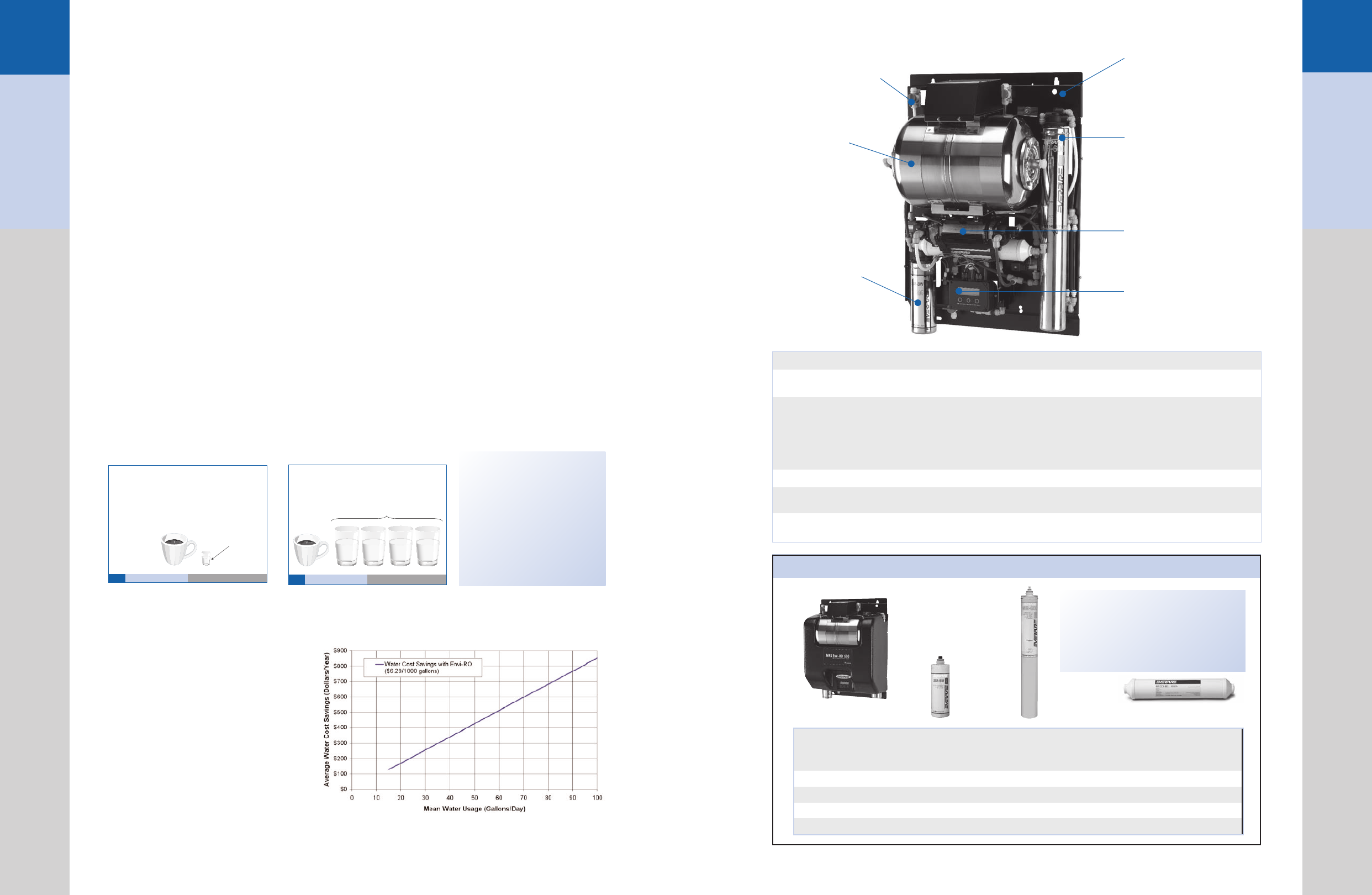

Dual mounting options offer

greater installation flexibility

2SR-BW Cartridge manages

scale formation, extending

the life of the MR-600

RO Cartridge.

6-Gallon total capacity

RO water storage

tank provides ample

reserve volume for

instantaneous demands

Micro-processor based

control with digital display

provides system status and

operator interface

Unique dual headed pump

boosts output and overall

system efficiency

Inlet and outle

t connections are smartly

located along the top of the unit,allowing

quick and easy connection to

the distribution piping

MR-600 RO Cartridge delivers

2 times the daily production

volume, when compared to

conventional RO membranes

of similar size

See page 28-29 for

additional reverse

osmosis systems.

A conventional RO system requires

five volumes of water to produce

one volume of water that can be

dispensed. The remaining four

volumes are discharged to drain.

The MRS ENVI-RO 600 wastes only a

small fraction of the total volume,

thus reversing the ratio of waste-

to-product RO water relationship.

MRS ENVI-RO 600 SYSTEM/REPLACEMENT CARTRIDGES

System

Part

Number

System Dimensions

ShipWeight

H XW X D

(inches)

MRSENVI-RO 600 System

EV9970-38 32 x 23 x 13.6 85

MR-600 Cartridge EV9627-13 N/A ——

2SR-BW Cartridge EV9627-14 N/A ——

MRS ENVI-RO In-Line Post Filter

EV9627-15 N/A ——

MRSEnvi-RO 600

2SR-BW Cartridge

MR-600 Cartridge

MRSEnvi-RO In-Line Post Filter

Remote Sub-Micron Sediment and Carbon

Filtration equipment is required. The Everpure

Coldrink Series,CB20-302E or CB20-312E are

suitable pre-treatment systems. Contact

Everpure for assistance when configuring a

complete system package.

Features Benefits

A nominal 600 Gallons per Day of permeate (RO) water. This

production volume is further supplemented by the blending system

Depending onTDS levels and blend setting, total system output

could reach 1,000 gallons per day

Dual Output design is capable of producing two water qualities:

Outlet 1 -TheTDS of this water is very low – typically >90% removal

of the dissolved minerals from the tap water

Outlet 2 -This outlet can produce a wide range of water qualities. It

combines or“blends” two sources of water - RO and FilteredTap water

Outlet 1 - Ideally suited for applications such as flash steamers and

other equipment that“boils away” the water

Outlet 2 – Perfect for specialty coffee and other applications

requiring a custom tailored level of dissolved minerals

Compact wall mount design Only 32”H x 23”W x 13.6”D

System operation is tailored to the water quality at each location

to maximize the highest recovery possible

Provides the highest level of water savings while maintaining

exceptional membrane life

High production rates reduce the need for bulky external storage

tanks and emergency tap water by-pass system

Conserves valuable floor space and provides consistent delivery of

ingredient quality water

To determine what this water savings might mean over the course of a year, refer to the graph on

the right. If an establishment requires 80 gallons per day of RO treated water, the MRS E

NVI-RO 600

system could reduce the volume of water

sent to drain by 100,000 gallons per year

over a low efficiency system. With water

and sewer averaging about $6.30

per 1,000 gallons, a $630.00 annual

re

duction in water and sewer costs

could be realized. The operator enjoys

a substantial reduction in operating

expense, and less stress is placed on

the world's dwindling water supply.

Water Cost Savings per Store vs. Water Consumption with MRS ENVI-RO 600

(results may vary based on supply water chemistry and level of pre-treatment)