HIGH EFFICIENCY DECATHLON (HD) SERIES GAS FRYERS

CHAPTER 3: INSTALLATION

3-7

3.5 Gas Specifications

CE ONLY

(

Altitudes of 2000 feet or less

)

EQUIPMENT

PRESSURE

MODEL

INPUT

(kW)

GAS

TYPE

ORIFICE

(MM)

ORIFICE

PART NO.

QTY

MBAR INCH W.C.

D20G 15,0

G20

G25

G31

2,40

2,40

1,51

810-2060

810-2060

810-2059

2

2

2

10,0

15,0

27,0

4,0

6,0

10,8

D50G 30,0

G20

G25

G31

2,40

2,40

1,51

810-2060

810-2060

810-2059

4

4

4

10,0

15,0

27,0

4,0

6,0

10,8

D60G 37,5

G20

G25

G31

2,40

2,40

1,51

810-2060

810-2060

810-2059

5

5

5

10,0

15,0

27,0

4,0

6,0

10,8

D80G 37,5

G20

G25

G31

2,40

2,40

1,51

810-2060

810-2060

810-2059

5

5

5

10,0

15,0

27,0

4,0

6,0

10,8

NOTE: Outlet gas pressure must be adjusted strictly within the above requirements 5 to 10 minutes after the appliance is operating.

(Pilot Flame Adjustment: Turn the pilot adjustment screw clockwise/counter-clockwise until the desired flame-volume is achieved.)

3.6 Gas Conversion Procedures

DANGER

This appliance was configured at the factory for a specific type of gas. Converting from

one gas type to another requires the installation of specific gas-conversion components.

Switching to a different type of gas without installing the proper conversion

components may result in fire. NEVER ATTACH THIS APPLIANCE TO A GAS

SUPPLY FOR WHICH IT IS NOT CONFIGURED!

Conversion of this appliance from one type of gas to another should only be

performed by qualified, licensed, and authorized installation or service personnel, as

defined in Section 1.6 of this manual.

Contact factory with the following information when performing conversions:

• Fryer Serial Number

• Fryer Model Number

• Gas Type

• Operating Altitude

Conversions can only be executed by qualified, factory-authorized personnel.

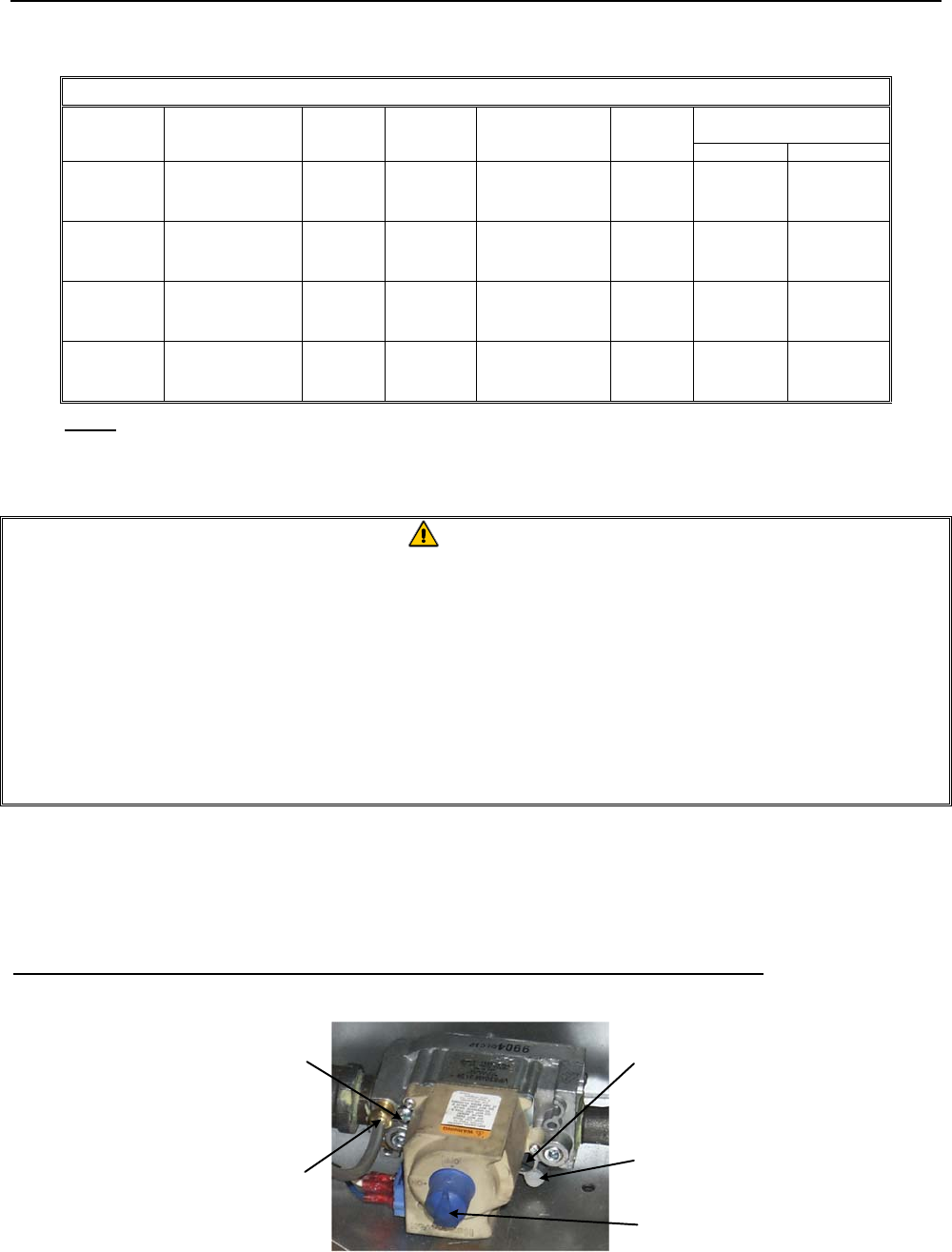

Pressure flow adjustment

(remove cover screw to

access)

ON/OFF

Gas-Cock Knob

Pilot gas supply

connection.

Regulator Vent

Pilot pressure adjustment

(remove cover screw to

access)

Typical non-CE gas valve for electronic-ignition equipped fryers.