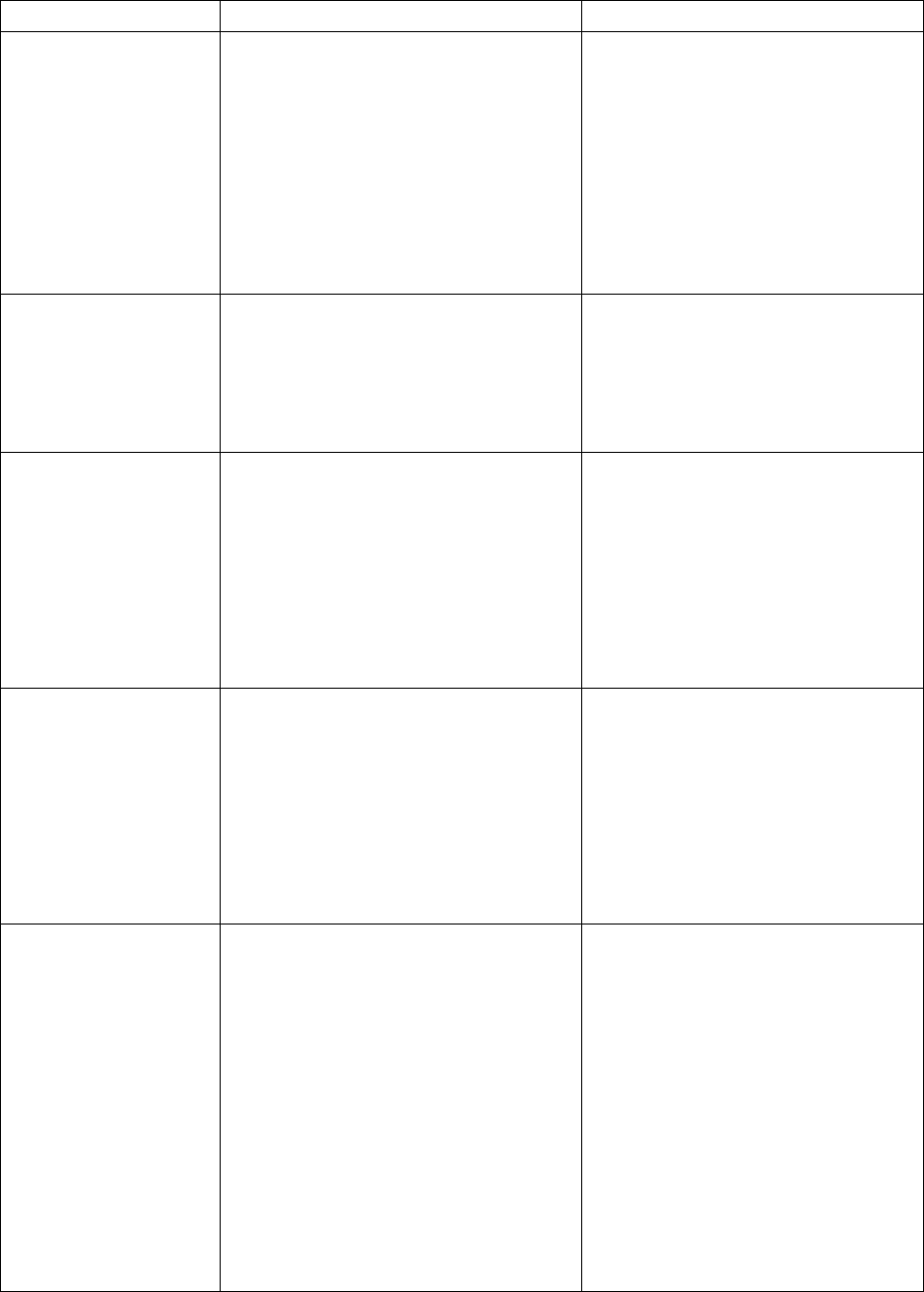

6-3

Problem Probable Causes Corrective Action

Fryer repeatedly

cycles on and off

when first started.

Fryer is in melt-cycle mode.

This is normal. The standard

operational mode for the controller

is for the elements to cycle on and

off until the temperature in the

frypot reaches 180ºF (82ºC). The

purpose of the melt-cycle is to

allow controlled melting of solid

shortening to prevent scorching

and flash fires or damage to the

element.

Fryer does not heat

after filtering.

Drain valve is open.

This fryer is equipped with a drain

safety switch that prevents the

heating element from being

energized if the drain valve is not

fully closed. Verify that the drain

valve is fully closed.

Fryer heats until

high limit trips with

heat indicator ON.

Temperature probe or controller has

failed.

If available, substitute a controller

known to be working for the

suspect controller. If the substitute

controller functions correctly,

order a new controller. If

substitution of the controller does

not resolve the problem, the most

likely cause is a failed temperature

probe.

Fryer heats until

high limit trips

without heat

indicator ON.

Contactor or controller has failed.

If available, substitute a controller

known to be working for the

suspect controller. If the substitute

controller functions correctly,

order a new controller. If

substitution of the controller does

not resolve the problem, the most

likely cause is a contactor failed in

the closed position.

Fryer stops heating

with heat indicator

ON.

The high limit thermostat or

contactor has failed.

The fact that the heat indicator is

ON indicates that the controller is

functioning properly and is calling

for heat. The high limit thermostat

functions as a normally closed

switch. If the thermostat fails, the

"switch" opens and power to the

elements is shut off. If the

contactor fails to close, no power is

supplied to the elements.

Determining which component has

failed is beyond the scope of

operator troubleshooting. Call

FASC.