Part #GCGTRAINING06 (03/03/08) Page 5

WHAT IS A CHAIN GRIDDLE

Commercial chain restaurants impose strict food procedures

on franchise owners and operators to guarantee the quality

and consistency of the product. Beef burgers, hamburgers,

french fries, onion rings, fried chicken and tortillas for

example, must meet rigid standards of quality involving the

ingredients used, the recipes followed, storage and, not least,

the cooking temperature and time of cooking.

Accuracy of temperature control and the heating stability of

the cooking surface are essential in maintaining consistent

quality in the product. Control and stability are the two

primary features in the new chain griddle. As compared with

previous gas griddles of the same kind, temperature control

of heating zones in the chain griddle is far tighter and more

precise.

Two features provide precision control. One feature is a

burner for every foot of griddle surface. The other is that each

burner is electronically monitored for temperature control.

As a result, at 30,000 BTU using natural gas, there is excellent

energy management and power recovery.

Temperature sensors are embedded in the griddle plate.

Each sensor is close to the plate surface where the load

is. The eect of this arrangement is to achieve an even

temperature gradient across the plate. Thanks to the

electronic monitoring feature, a much faster response to

changes in surface temperature is achievable in the chain

griddle than in previous units.

The smoother temperature gradient per unit surface area

and accurate temperature control has made the chain

griddle an instant success. This simple explanation of the two

main features of the unit is what makes it so special. Without

fast response and a smooth gradient, the chain griddle

would be just another design among many.

Explaining why the unit is special is one thing and

understanding how it works in another. Service technicians

need to know this to have complete condence when

servicing the unit. We describe how it works in the next part

of this section.

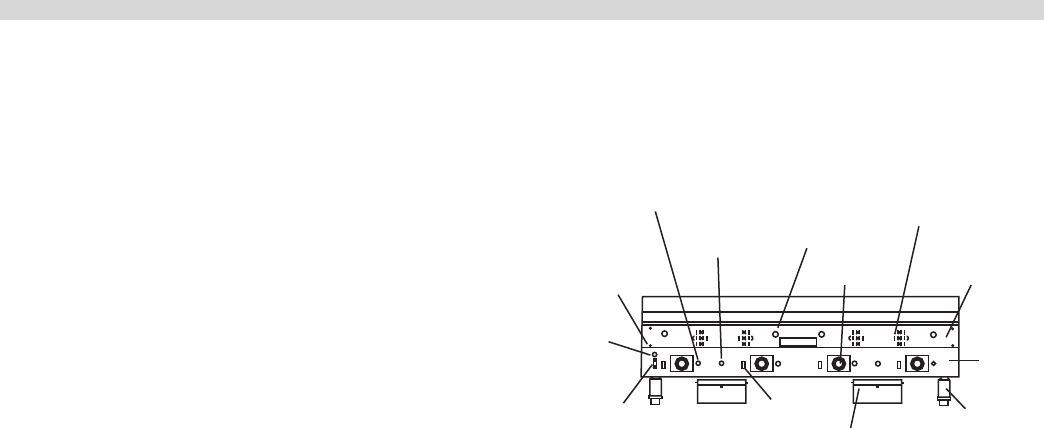

Figure 1 -Front view of counter-top chain griddle

Burner ON amber

indicator light

Pilot ON green

indicator light

Flame

viewport

Zone

thermostat

Air vents

Removable top

access panel

Hinged

drop-down

bottom half

access

panel

Leg of counter-top

style griddle

Grease tray

Zone power

switch

Main power

switch

Main power

ON

green

indicator

light

Securing

fasteners

for removable

top

access panel

How Does it work?

When the main power switch is turned on, the power

indicating lamp is illuminated and power is applied to the

thermostat input of the ignition modules. This will initiate

the pilot ignition sequence. The ignition module supplies a

spark ignition at the pilot burner and will energize the pilot

solenoid valve for a maximum trail period of 50 seconds.

If the pilot ame ignites and is sensed within the 50 second

period, the main burner output of the ignition module will

be energized. The pilot indicating lamp will illuminate. The

main burner solenoid valves are then controlled by the

thermostats. As a thermostat calls for heat, it will energize

its output and the main burner valve along with the burner

indicating lamp will energize. The main burner will cycle with

the thermostat.

There is only one trial for ignition. If the pilot ame is not

sensed during the trail period, the ignition module will lock

out. All ignition module outputs will be de-energized. To reset

the ignition module the main power switch must be turned

o for a period of 30 seconds.