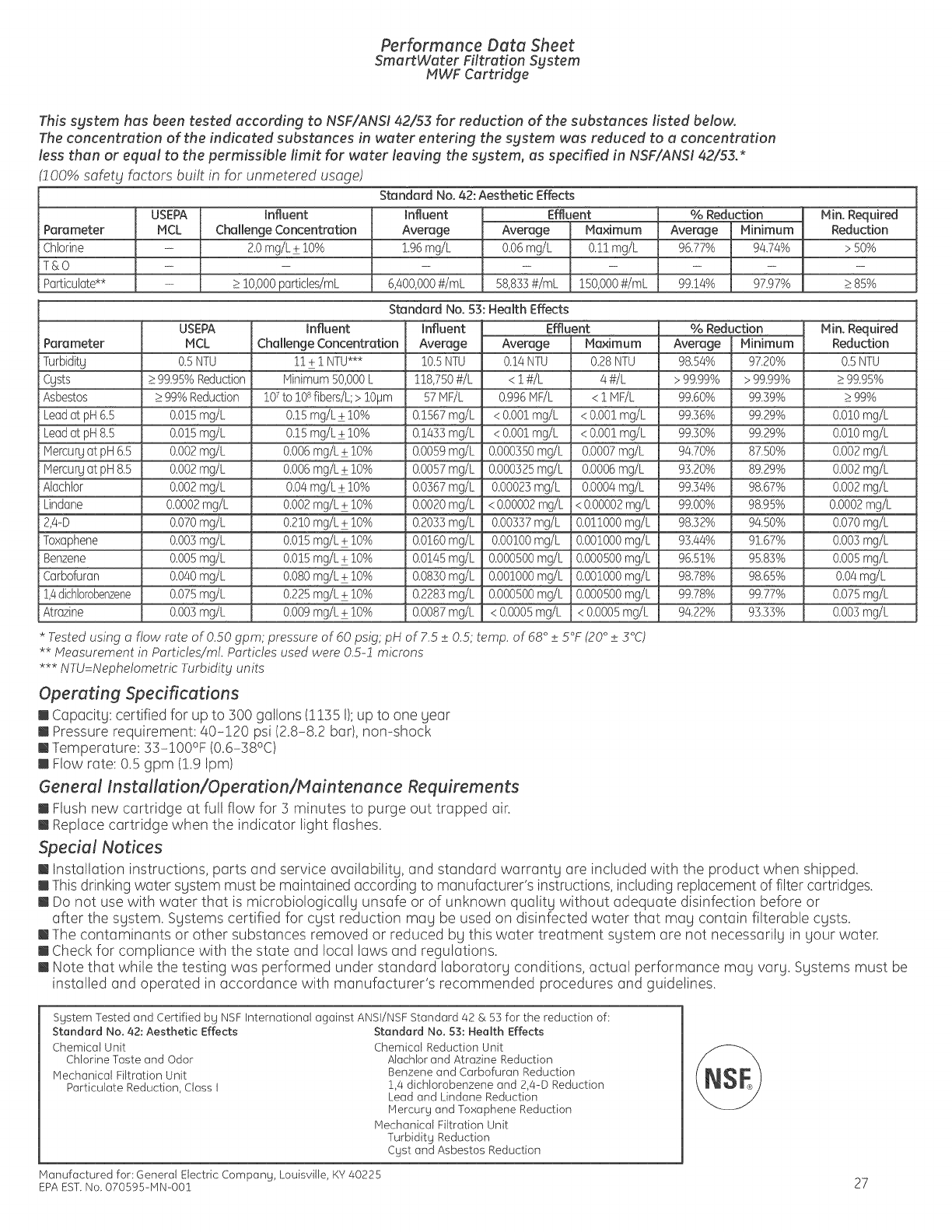

Performance Data Sheet

SmartWater Filtration System

MWF Cartridge

This sgstem has been tested according to NSF/ANSI 42/53 for reduction of the substances listed below.

Theconcentration of the indicated substances in water entering the system was reduced to a concentration

less than or equal to the permissible limit for water leaving the system, as specified in NSF/ANS! 42/53.*

(100% safetb, factors built in for unmetered usage)

USEPA Influent

Parameter MICL Challenge Concentration

Chlorine -_- 2,0mg/L_.10%

T&O - -

Particulate** - _ 10,000partides/mL

Standard No,42: Aesthetic Effects

Influent Effluent

Average Average /Maximum

1,96mg/L 0,06mg/L 0,11mg/L

6,400,000#/mL 58,833#/mL 150,000dmL

% Reduction

Average /Minimum

96.77% 94.74%

99.14% 97.97%

Parameter

Turbiditg

Cgsts

Asbestos

LeadatpH6,5

LeadatpH8,5

I'qercurgatpH6,5

1'4ercurgatpH8,5

Aiachlor

Lindane

2,4--D

Toxaphene

Benzene

Carbofuran

1,4dichlorobenzene

Atrazine

USEPA

MICL

0.5NTU

299.95%Reduction

2 99%Reduction

0.015mg/L

0.015mg/L

0,002mg/L

0,002mg/L

0,002mg/L

0.0002mg/L

0.070mg/L

0,003mg/L

0,005mg/L

0,040mg/L

0,075mg/L

0.003mg/L

Standard No. 53: Health Effects

Influent

Challenge Concentration

11+1NTU***

Minimum50,000L

107to108fibers/L;>10tJm

0,15mg/L+.10%

0,15mg/L+.10%

0,006mg/L+ 10%

0,006mg/L+ 10%

0,04mg/L+10%

0.002mg/L+ 10%

0.210mg/L+ 10%

0,015mg/L+ 10%

0,015mg/L+ 10%

0,080mg/L+ 10%

0,225mg/L+ 10%

0.009mg/L+ 10%

Influent

Average

10.5NTU

118,7%#/L

57MF/L

0.1567mg/L

0.1453mg/L

0.0059mg/L

0.0057mg/L

0.0367mg/L

0.0020mg/L

0.203J'mg/L

0.0160mg/L

0.0145mg/L

0.0830mg/L

0.2283mg/L

0.0087mg/L

Effluent

Average

0.14NTU

<1#/L

0,996MF/L

<0,001mg/L

<0,001mg/L

0.000350mg/L

0.000325mg/L

0.00023mg/L

<0.00002mg/L

0.0033r1-7mg/L

0,00]00rng/L

0.000500mg/L

0,00]000mg/L

0.000500mg/L

<0.0005mg/L

/Maximum

028 NTU

4#/L

<] MF/L

<0,00] mg/L

<0,001mg/L

0.0007mg/L

0.0006mg/L

0.0004mg/L

<0.00002mg/L

0.011000mg/L

0.001000mg/L

0.000500mg/L

0.001000mg/L

0.000500mg/L

<0.0005mg/L

% Reduction

Average /Minimum

98.54% 97.20%

>99.99% > 99.99%

99.60% 99.39%

99.36% 99,29%

99.30% 99,29%

94.70% 87.50%

93.20% 89,29%

99.34% 98,67%

99.00% 98.95%

98.32% 94.50%

93,44% 9].67%

96.51% 95,83%

98.78% 98.65%

99.78% 99.77%

94.22% 93.33%

Testedusing a flow rote of 0.50 gpm; pressure of 60 psig; pH of 7.5 +_0.5; temp. of 68° _+5°F (20°_+3°C)

** Measurement in Particles/m/. Particles used were 0.5-1 microns

*** hlTU=hlephe/ometric Turbiditg, units

Mlin.Required

Reduction

>50%

285%

Mlin.Required

Reduction

05 NTU

99.95%

99%

0,010mg/L

0,010mg/L

0,002mg/L

0,002mg/L

0,002mg/L

0.0002mg/L

0.070mg/L

0,003mg/L

0,005mg/L

0,04mg/L

0,075mg/L

0.003mg/L

Operating Specifications

M Capacitg: certified for up to 300 gallons (1135 I);up to one gear

M Pressure requirement: 40-120 psi (2.8-8.2 bar), non-shock

I Temperature: 33-100% (0.6-38°C)

M Flow rate: 0.5 gpm (1.9 Ipm)

General lnstallation/Operation/Haintenance Requirements

M Flush new cartridge at full flow for 3 minutes to purge out trapped air.

M Replace cartridge when the indicator light flashes.

Special Notices

I Installation instructions, parts and service availabilitg, and standard warrantg are included with the product when shipped.

M This drinking water sgstem must be maintained according to manufacturer's instructions, including replacement of filter cartridges.

M Do not use with water that is microbiologicallg unsafe or of unknown qualitg without adequate disinfection before or

after the sgstem. Sgstems certified for cgst reduction mag be used on disinfected water that mag contain filterable cgsts.

I The contaminants or other substances removed or reduced bg this water treatment sgstem are not necessarilg in gour waten

M Check for compliance with the state and local laws and regulations.

M Note that while the testing was performed under standard laboratorg conditions, actual performance mag varg. Sgstems must be

installed and operated in accordance with manufacturer's recommended procedures and guidelines.

Standard No. 42: Aesthetic Effects

Chemical Unit

Chlorine Taste and Odor

Mechanical Filtration Unit

Particulate Reduction, Class I

Sgstem Tested and Certified bg NSFInternational against ANSI/NSF Standard 42 & 53 for the reduction of:

Standard No. $3: Health Effects

Chemical Reduction Unit

Alachlor and Atrazine Reduction

Benzene and Carbofuran Reduction

1,4 dichlorobenzene and 2,4-D Reduction

Lead and Lindane Reduction

Mercurg and Toxaphene Reduction

Mechanical Filtration Unit

Turbiditg Reduction

Cgst and Asbestos Reduction

Manufactured for: General Electric Compang, Louisville, KY40225

EPAEST.No.070595-MN-001 27