1. DAMPER IS INSTALLED OUTSIDE OF WALL PLANE

OFSD-XXX

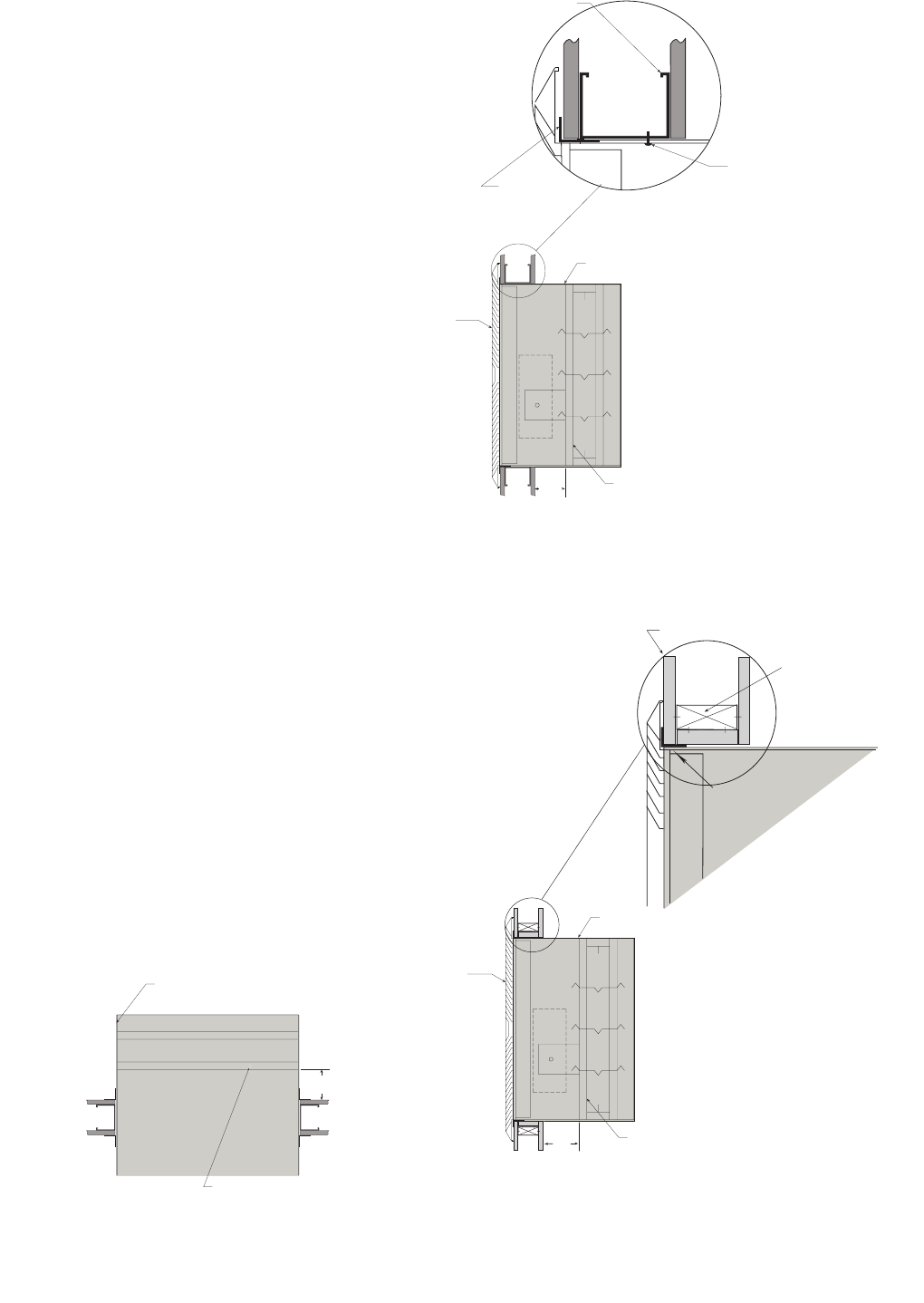

Figure 1 shows two approved installations for

combination fire smoke dampers: 1) “Through the

grille access” and 2) installation in continuing duct.

To provide "through the grille" access to the damper

actuator, the damper is located toward the back of the

sleeve and the actuator is installed between the damper

and grille. Actuator and damper can be accessed and

serviced by removing the grille. To provide access to the

damper actuator for continuing ductwork, refer to the

requirements of NFPA 90A.

ODFD-XXX, OFD-XXX, and OSSFD-XXX: Figure

1 shows two installations that are also approved for

curtain fire dampers. For access to inspect the damper

and fusible link, refer to the requirements of NFPA 90A.

2. CLEARANCE REQUIREMENTS

There is no minimum clearance requirement between

the wall/floor opening and the sleeve exterior (with

thermal blanket attached). However, to facilitate

installation, clearances between the wall/floor opening

and the damper sleeve are recommended. although

there is no maximum allowable clearance, the minimum

overlap requirements between the wall/floor and the

flange/retaining angle must be met. On grill mount

installations the flange must overlap the wall/floor by

1⁄2 in. (13mm). On continuous duct installations, the

retaining angles must overlap the wall/floor by 1 in.

(25mm). Because no clearances are required betweeen

the wall/floor opening and the sleeve, dampers may not

be installed in the plane of the wall using this installation

method.

3. DUCT TO SLEEVE CONNECTIONS

Dampers are supplied with actuators (on applicable

models) and sleeves from the factory and can be

installed without the need for additional field installed

sleeves.

Sleeve gauges of 20-14 (.9mm - 2mm) are to be used.

UL Standard 555 requires all ducts to terminate at fire

damper sleeves. Sleeve thickness must not be less than

the gauge of the connecting duct.

Duct to sleeve breakaway connections must be of the

type described on page 5. Factory furnished round duct

collars on type R and CR dampers are also considered

to be breakaway connections and may be used.

Steel stud

5/8 in . x 1 in. 16 ga.

angles minimum

(Refer to Section 4)

Grille

(Supplied

by others)

Factory Supplied

Thermal Blanket

Factory Supplied

Thermal Blanket

7 1/2 in.

Max.

7 1/2 in.

Max.

Fire damper or

combination fire

smoke damper

Fire damper or

combination fire

smoke damper

#10 sheet metal screws

spaced 6 in. on center and

maximum of 2 in. from the

corners (minimum of 2

screws per side). Screw into

rear portion of the studs so

as to avoid space conflicts

with the grille assembly.

“Duct Continues”

Note: Both installations may be vertical or horizontal.

W

ooden Stud Construction

Gypsum Wallboard

Stud or Runner

1in. x 1 in. 16 ga.

angle minimum

(Refer to section 4)

(Duct Terminates)

In wood stud construction,

gypsum wallboard must cover

all wood stud surfaces.

Grille

(Supplied

by others)

Factory Supplied

Thermal Blanket

Fire damper or

combination fire

smoke damper

6 1/2 in.

Max.

Figure 1: Installation configurations for ‘Out of Wall’ curtain fire dampers and combination fire smoke dampers.

“Duct Terminates” Metal Stud

“Duct Terminates” Wood Stud

Steel stud

5/8 in . x 1 in. 16 ga.

angles minimum

(Refer to Section 4)

Grille

(Supplied

by others)

Factory Supplied

Thermal Blanket

Factory Supplied

Thermal Blanket

7 1/2 in.

Max.

7 1/2 in.

Max.

Fire damper or

combination fire

smoke damper

Fire damper or

combination fire

smoke damper

#10 sheet metal screws

spaced 6 in. on center and

maximum of 2 in. from the

corners (minimum of 2

screws per side). Screw into

rear portion of the studs so

as to avoid space conflicts

with the grille assembly.

3