10

System

Considerations

Air Plenum Design Guidelines

To assure optimum performance and be able to use

the system effect coefficients below, the following

guidelines should be adhered to in the plenum design:

1. Flexible connections at the inlet are recommended to

isolate vibration. The inlet connection can be square

(connected to the inlet panel) or round (connected

to an optional inlet collar).

2. Plenum walls should be at least one-half of a wheel

diameter away from the fan.

3. Dampers or coils should be at least three-quarters

of a wheel diameter away from the fan to assure an

even velocity distribution through them.

4. For fans operating in parallel:

Have one wheel diameter clearance between

adjacent fans.

#BDLTUPQDMVUDIFTPSCBDLGMPXDPOUSPMEBNQFST

should be used to prevent windmilling of wheels if

fans are started or stopped at different times.

Do not select fans near the top of the fan curve to

prevent unstable operation.

8IFFMTTIPVMECFTFMFDUFEBTDPOUSBSPUBUJOH

$8$$8$8FUDUPJNQSPWFBJSGMPXQBUUFSOT

between the fans.

See AMCA Publication 201 for additional information

on this subject.

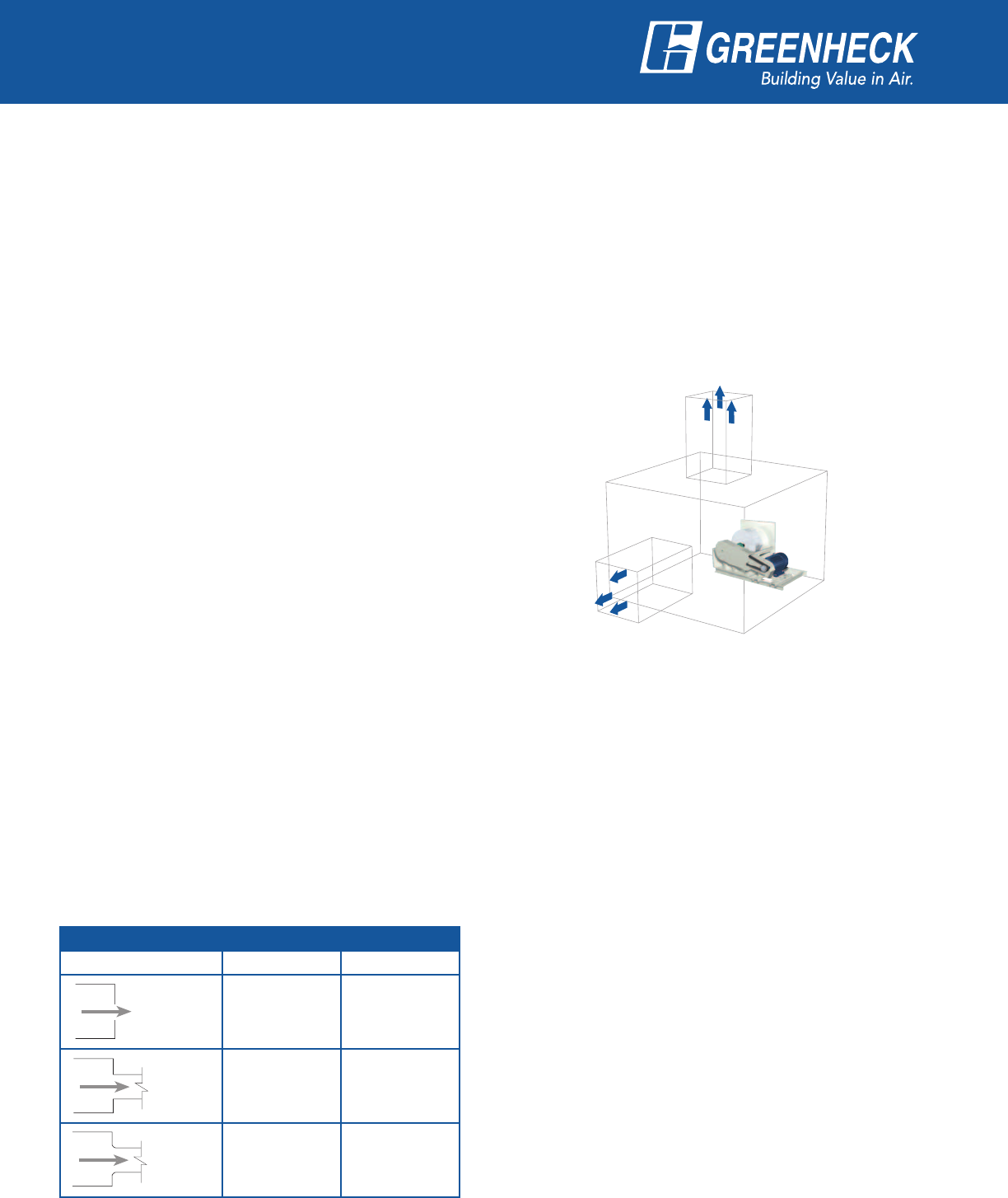

Duct System Effect

Reduction in cataloged air performance due to a plenum

around the fan is called a system effect. System effect

is a pressure loss, which must be added to the total

external static pressure of the duct system in order to

make the proper fan selection from catalog data. The

pressure loss calculation is based on the velocity of

the air in the discharge ductwork. As shown below, it

is derived by multiplying the appropriate coefficient by

the velocity pressure.

Effects of Air Density

Ratings in the fan performance tables and curves of

this catalog are based on standard air: clean and dry

XJUIBEFOTJUZPGMCTGU

3

at 70°F at a pressure of

29.92 in. of mercury. A change in elevation, temperature

or the type of gas handled will affect density. A fan

running at a constant speed and installed in a fixed

system will experience changes in pressure output and

horsepower consumption if the density of the airstream

varies. The air volume delivered by the fan will remain

constant regardless of air density.

Example of Performance Correction

Select a fan to meet the following requirements:

7PMVNF DGN

4UBUJD1SFTTVSF JOXH

Airstream Temperature: 70°F

Installation Elevation: 13,000 ft.

Plenum Discharges (ducted): 24 in. x 27 in. Radial

24 in. x 27 in. Axial

1. The selection is at non-standard atmospheric

conditions and must be corrected to standard

DPOEJUJPOT UP VTF DBUBMPHFE EBUB 7PMVNF SFNBJOT

at 20,000 cfm, since the volume delivered is not

affected by air density.

2. An air density correction factor must be applied to

the static pressure. For an elevation of 13,000 ft. and

a temperature of 70°F, 1.6 is the required correction

GBDUPS5BCMF"6TFUIFDPSSFDUJPOGBDUPSUPBEKVTU

the static pressure by multiplying the required static

pressure by the correction factor.

JOXHYJOXH

Discharge Configuration Coefficients

Discharge Radial Axial

Unducted

2.0 2.3

Ducted

1.8

Ducted

with Bell

1.1 1.4

5"#-&%JTDIBSHF$PFGGJDJFOUT

24 in. x 27 in.

(Radial)

24 in. x 27 in.

(Axial)