12

Other Options and Accessories

Electrical

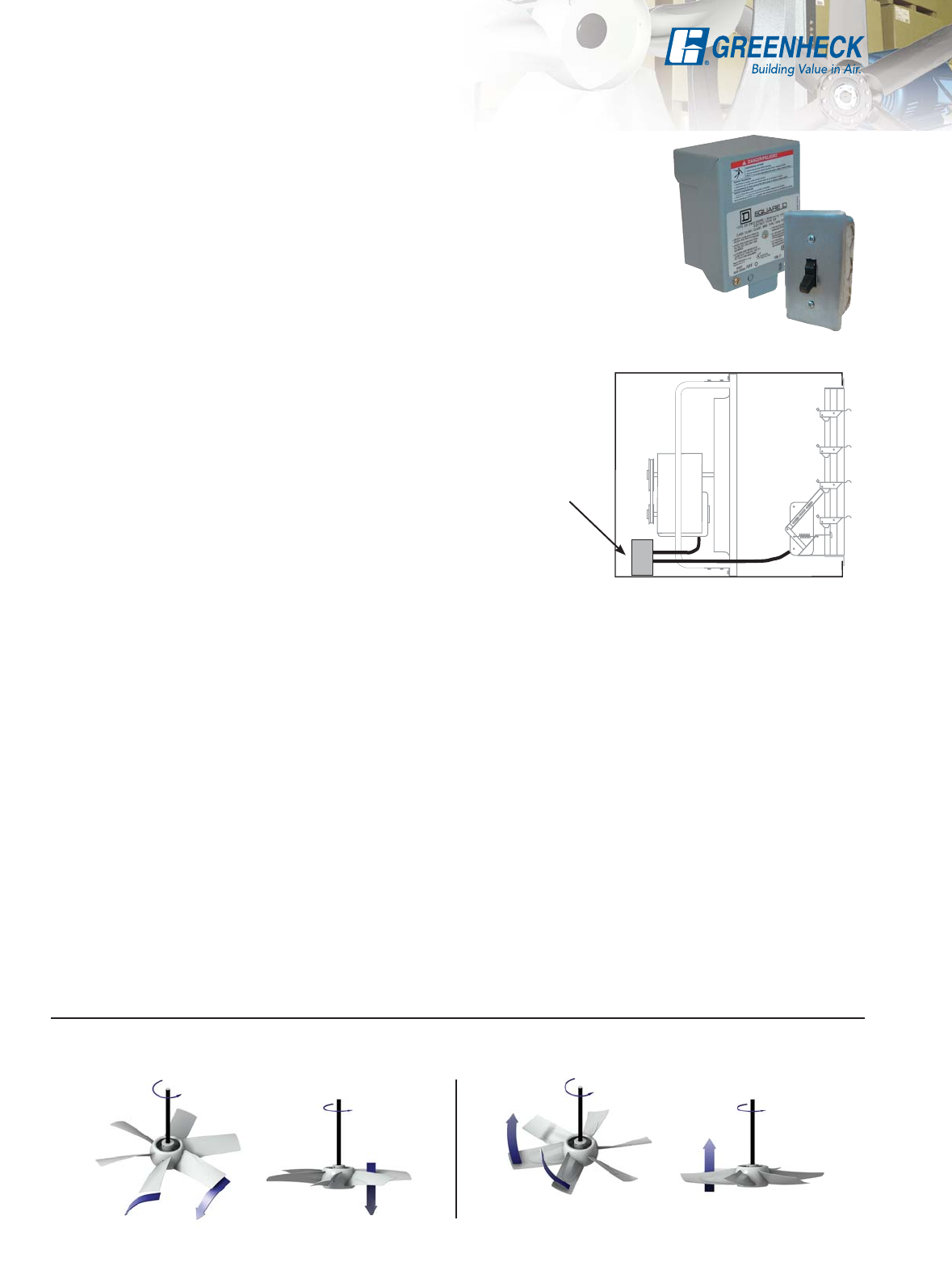

Disconnect Switches

Toggle type and heavy duty disconnect switches are available for positive

electrical shut-off and safety in servicing fans. The following switches are

available to meet individual electrical requirements and can be factory

mounted or shipped loose for field mounting. Wiring from the motor to the

disconnect box is provided with factory mounted disconnect switches.

• NEMA-1 - General purpose

• NEMA-3R - Rainproof

• NEMA 4 - Watertight

• NEMA-3R & NEMA 4 - Heavy Duty

• NEMA-7 & 9 - for Class 1 and Class 2 hazardous locations.

1-Point Wiring

Available when the following items are selected: common

voltages on the motor and the actuator, disconnect mounted

and wired and a wall housing. The wires are pulled from the

motor and the actuator on the damper to the disconnect box.

(Hard wiring of the components to the disconnect switch is by

others.)

Exception: When a specific voltage is not available on the

actuator, Greenheck will provide a hard wired transformer

to the actuator. Greenheck will then pull the wires from the

transformer to the disconnect box.

UL/cUL 705

All belt and selected direct drive fans with TE standard efficiency, single speed motors are available with the

UL705 listing for electrical.

Extended Wiring Pigtail

Available only in conjunction with factory mounted disconnect switches, liquid tight wiring pigtails allow direct

hook-up to the power supply which eliminates field wiring at the fan. Internal or external power supply can be

specified.

End Switches

Factory mounted end switches allow the damper to open completely before the fan is energized. This will reduce

the back pressure and brake horsepower load on the fan motor at startup. (Field supplied motor starter with a

relay is required to complete the wiring on a system using an end switch.)

Options

Coatings

A variety of special coatings ranging from enamels to phenolics are available for decorative or protective

purposes. When a special coating is selected for the fan, all accompanying accessory items are also coated

unless so specified. Consult your local representative for more details.

Welded and Painted Fan Construction

For applications where extra heavy construction is required, welded steel construction is available. With this

option, all stationary connections which are normally bolted are welded and coated with an industrial grade

paint. This option applies to belt drive level 3 fans and direct drive level 2 and 3 fans only.

1-Point wiring

Junction Box

or Disconnect

Propeller Fan Rotation Guide

Propeller blade should cup and throw the air when rotating in the correct rotation as shown below.

NEMA-3R

and NEMA-1