Page 2 Crathco

®

Remote Beverage Freezers

OPERATOR’S SAFETY PRECAUTIONS

IMPORTANT: Failure to comply with the following safety precautions may result in severe personal injury or damage

to the machine.

1. Read and understand the operating instructions in this manual thoroughly. Only allow properly trained persons to

operate this machine.

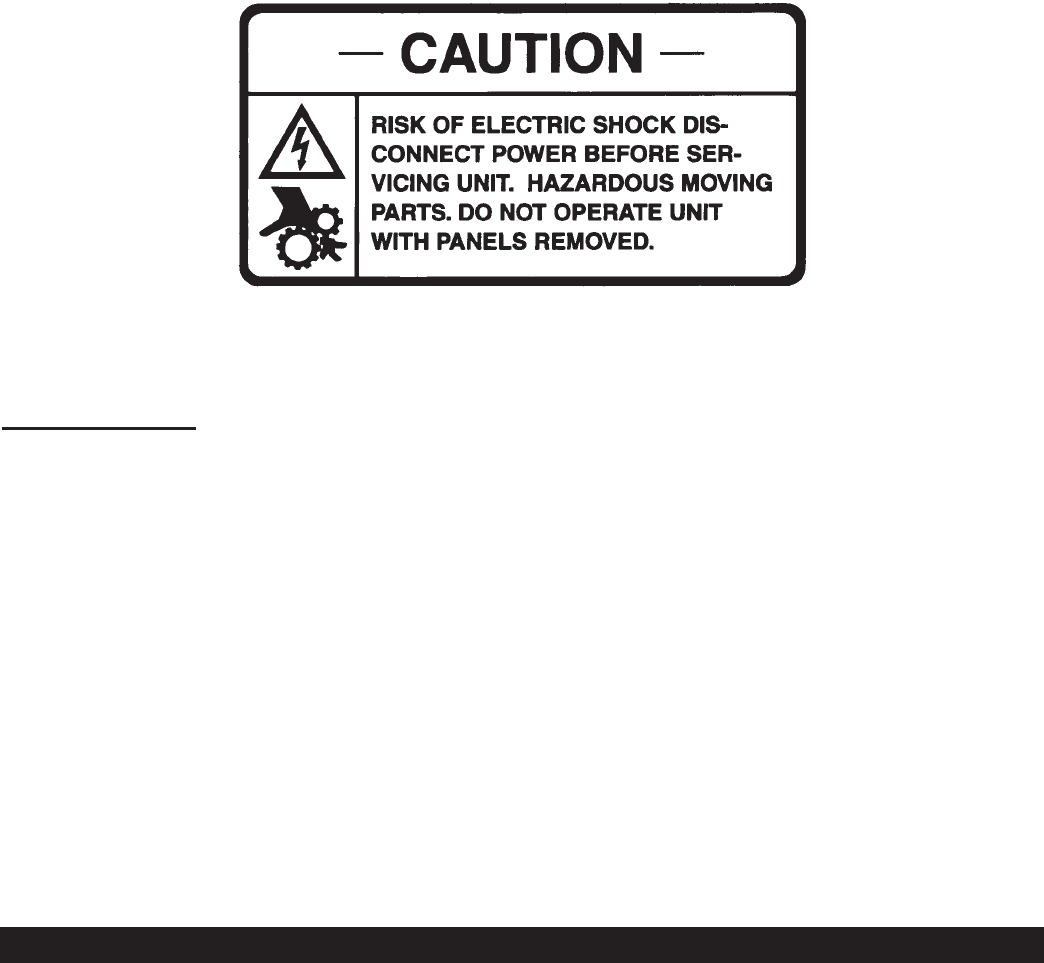

2. Note all warning labels on the freezer. If any warning labels are missing or damaged replace them immediately.

3. Do not wear loose fitting garments or jewelry which could cause a serious accident.

4. Stay alert at all times during operation.

5. Keep operating area clean.

6. Do not attempt any repairs unless the main power supply to the freezer has been disconnected. Contact

Grindmaster Technical Service for service assistance.

7. Do not put objects or fingers in the dispense plunger.

8. Do not operate freezer if any excessive noise or vibration occurs. Contact your authorized service agent.

9. Be certain machine is installed with adequate space for proper air circulation. (See installation section.) Failure

to provide sufficient ventilation will reduce freezer performance and void equipment warranty.

FREEZER APPLICATION AND SPECIFICATIONS

Remote Freezers

The freezer consists of a freezing cylinder with a rotating internal auger (dasher) that is belt-driven by an electric

motor. The auger scrapes frozen product off of the inside of the refrigerated cylinder.

Crathco remote beverage freezers are designed to operate in conjunction with a remote condensing unit or be

connected to a central refrigeration system. It is recommended that the condensing unit have no more than 2 1/2 hp

per barrel to ensure maximum efficiency. The refrigerant must be R404A (Dupont

®

HP62

®

). The refrigeration for each

barrel is controlled by the liquid feed solenoid. The liquid feed solenoid is opened and closed by the limit switch

attached to the drive motor. (When the product consistency reaches the desired point, the switch closes and

de-energizes the liquid feed solenoid 20 seconds later.) Twin units operate with each barrel independently. Quick

connect refrigeration connections are supplied with each unit. Each freezer is factory supplied with 5/8" suction and

3/8" liquid connections. The piping connecting the freezer with the remote condensing unit or central system should

be sized according to industry standards. The installer is responsible for sizing the refrigeration lines to the unit.

When properly operated and cared for, the remote freezers will provide many years of service. Proper care includes

regular cleaning and maintenance. To minimize the amount of maintenance necessary, follow the operating proce-

dures outlined in this manual.

There are four variations of the remote unit:

3341 – standard single barrel remote unit

3342 – standard twin barrel remote unit

3341A – single barrel remote unit with internal autofill system

3352 – dual barrel remote unit with internal autofill system

Located on the right, left and rear panels. (part # W0600218)