Page 16 Crathco

®

5000 Series Manual

Cleaning Following Complete Disassembly of Unit (cont.)

IMPORTANT: After disassembly, thoroughly scour each part of the freezer in a warm mild detergent

solution including the inside of the freezing cylinder and the mix storage hopper. Rinse each part with

clear water. Prepare a minimum of 3-1/2 gallons (13 liters) of sanitizing solution (Divorsol CX or equiva-

lent) following the manufacturer's instructions.

Note: Add 3 ounces (85.4 mg) of Divorsol CX to 3-1/2 gallons (13

liters) of 120° Fahrenheit (50° Centigrade) water to achieve a

concentration of 200 parts per million. Dip or wipe each part

in sanitizing solution and allow them to dry on clean paper toweling.

Reassembly

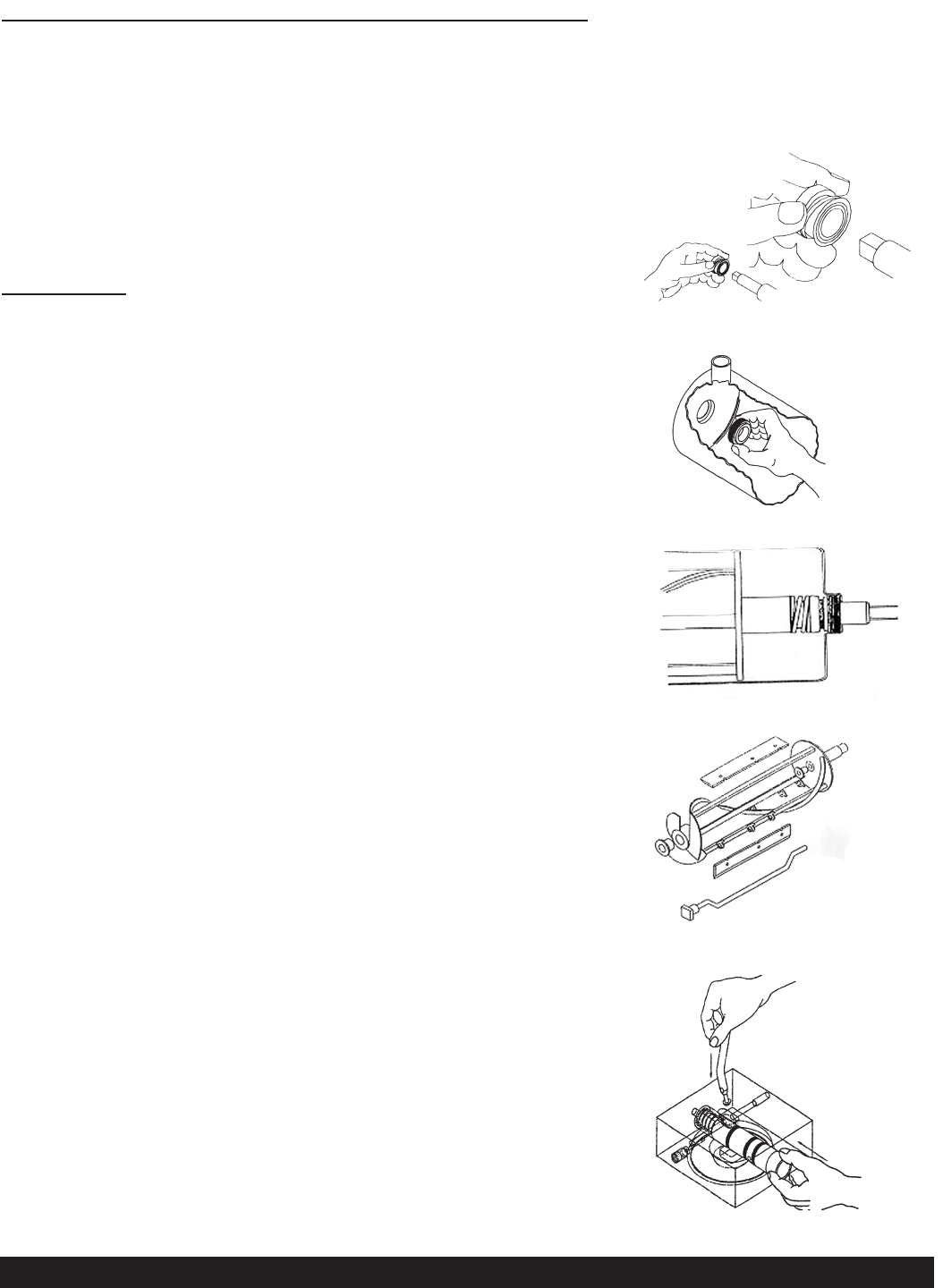

1. Wet the inner rubber lip of the rotary portion of the seal and the

back end of the auger shaft with water. Slide rotary portion of

assembly onto the auger shaft, RUBBER FIRST, with the smooth

sealing surface toward the back of the auger. (See Figure Z)

2. Insert the stationary portion of the seal into the grooved rubber boot with

the polished surface facing out (forward). Lubricate the grooved exterior

portion of the boot and insert it straight back into recess at the

back of the freezing cylinder, RUBBER FIRST.

(See Figure AA & BB)

Note: If the circular portion of the seal is white, make sure that the

groove is toward the rubber (back of freezer).

3. Reassemble the dasher assembly, as shown in Figure CC. Insert

the larger front and smaller rear white plastic bearings into

dasher, then slip in the stator rod. Attach scraper blades.

Carefully and slowly guide the auger into the freezing cylinder

taking care not to damage the seal assembly. Turn auger shaft

until it engages the square drive coupling.

4. Reassemble the dispensing valve assembly as shown in Figure DD.

Thoroughly wash and sanitize all components, lubricate the inside

bore of valve body with a thin film of food grade sanitary lubricant.

Reinstall the O-Rings on the plunger assembly and lubricate the

entire plunger. Reassemble the valve and replace the retainer pin.

Inspect and lubricate the large O-Ring and refit it into the rear of

the valve assembly. Install the valve assembly on the front studs

and tighten knobs until they are finger tight.

Do not use tools to tighten knobs.

Figure Z Reassemble rotary

portion of seal as shown

Figure AA Installing the stationary

portion seal

Figure CC

Figure DD

Figure BB Seal Assembly installed correctly