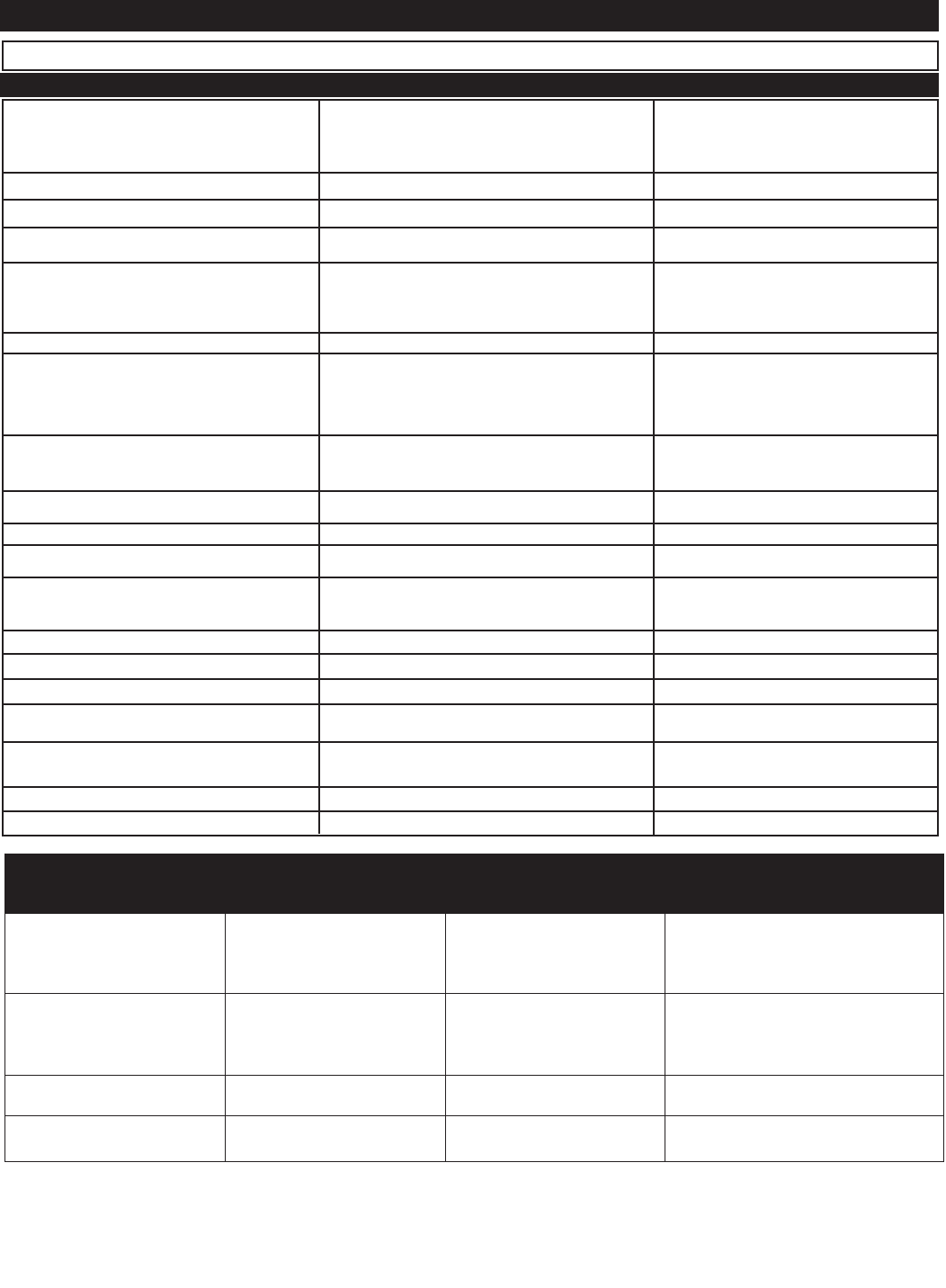

TROUBLESHOOTING GUIDE

Weak coffee

Strong coffee

Bitter coffee

Grounds in coffee

Brew basket overflowed

Unpleasant taste

Quantity of coffee dispensed

each throw is not the same

Circuit breaker trips

continuously

Control board displays “P-O”

Control board displays “ER2”

Water boiling (or steaming)

No lights are on

(including warmer lights)

Too much or not enough water in server

Spray head dripping

Hot water spigot dripping

Hot water spigot not dispensing

Warmer failure

Water solenoids not working

One indicator light will not illuminate

• Set to portion more coffee

• Readjust to finer grind

• Check spray temp; should be greater than

185°F/85°C

• Spray deflector broken or missing. Replace

• Use less coffee

• Use a coarser grind

• Use proper filter

• Position filter carefully

• Use no more than 3 1/2 oz. (100 grams) of

coffee

• Use a coarser grind

• You must dump old coffee and use fresh

new filter for each brew

• Clean, sanitize (delime)

• Delime machine

• Check hoses

• Turn screw on Dump Valve to open fully

• Check the length of time brewer runs

with watch

• Plug unit directly into outlet. Do not use

extension cord

• Designate single line for unit. Do not

use multi-outlet box

• Turn water supply on, then reset power

• Clean or replace water fill valve

• Replace if defective

• Check settings with actual temperature

• Check power at source

• Turn switch on

• Reconnect touchpad

• Readjust

• Delime unit

• Replace seal

• Delime tank

• Replace seat

• Check power source

• Replace fuse

• Replace defective heater

• Replace fuse

• Replace touchpad

• Not enough coffee used

• Grind is too coarse

• Water not hot enough

• Coffee bed has dry areas

• Too much coffee used

• Grind is too fine

• Paper filter collapsed during brewing

• Too much coffee

• Grind is too fine

• Double batching

• Water tank or brew basket needs cleaning

• Lime scale build-up

• Hose kinked

• Dump Valve not adjusted properly

• Defective timer

• Insufficient current due to

use of extension cord

• Insufficient current due to

overloaded line

• Water supply turned off

• Water fill valve on too long

• Problem with thermistor

• Temperature set too high

• Defective thermistor

• No power to brewer

• Power switch turned off

• Touch pad disconnected

• Water volume adjustment

• Lime build up in dump valve

• Faulty seal

• Tube limed up

• Defective valve seat

• Loss of power

• Bus fuse (5 Amp) on controller board is blown

• Defective warmer heater

• Bus fuse (1 Amp) on controller board is blown

• LED burned out

If you still need help, call an authorized dealer in your area or our Technical Service Department. You can reach Grindmaster Corporation’s Technical

Service Department at 800-695-4500 (USA & Canada only) or 502-425-4776 Monday-Friday, 8:00 AM - 6:00 PM EST. Please have the model and serial

number ready so that accurate information can be given.

Prior authorization must be obtained from Grindmaster Corporation’s Technical Services Department for all warranty claims.

Problem

Possible Cause

Solution

Error Messages

Problem Possible Causes Service Check Remedy

ER1

• Fill valve on for over

6 min. (This occurs

during initial fill on some units –

see Initial Start-up.)

• Check system for

water leaks.

• Correct any leaks and reset controller.

ER2

• Thermistor failure or

loose connections in

thermistor circuit.

• Ensure that connector

is securely attached to controller

and that thermistor is securely

connected.

• Secure connections and reset controller. If

error reoccurs, replace thermistor.

ER3

• Thermistor is reading

out of range.

• Check tank

temperature.

• Replace thermistor.

ER4

• No heating is detected • Verify power to heating element

and high limit operation

• Repair as needed.

B-SERIES Page 13