13

HELIO2

BLENDEr

HELIUM-OXYGEN

TROUBLESHOOTING

If the

HELIO2

Blender fails to function, consult the Troubleshooting

Guide below.

If problem cannot be solved by using Troubleshooting Guide, refer to the

HELIO2 Blender Service Manual (P/N 506124) available on the Internet;

www.precisionmedical.com or consult your Provider.

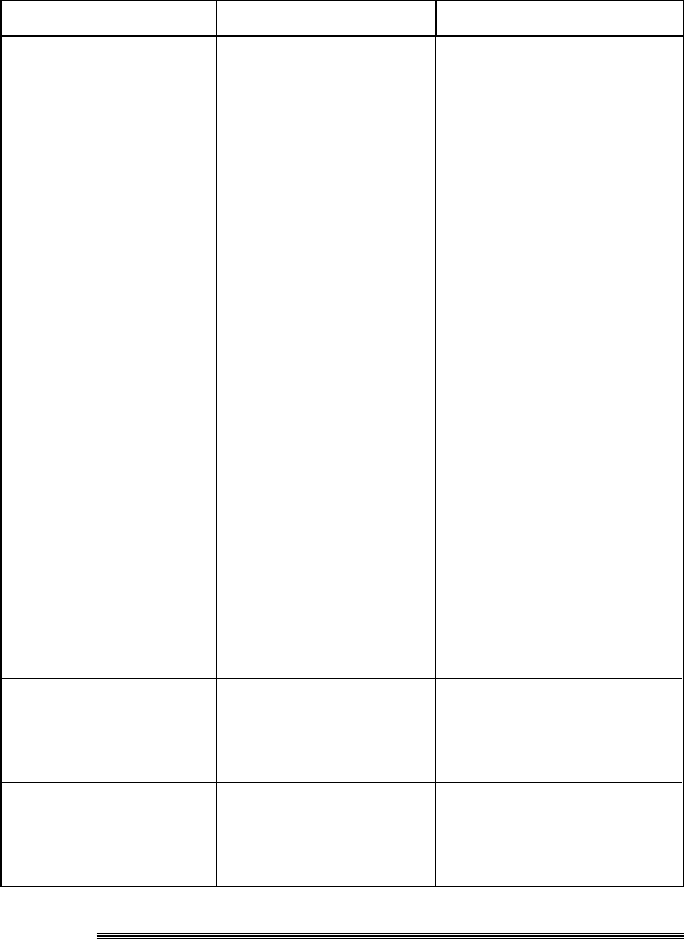

Problem Probable Cause Remedy

Oxygen

concentration

discrepancy

between Blender

setting and

alarmed Oxygen

Monitor / Analyzer

(greater than 3%)

1. •HIGH ow model,

ow requirement

below 15 lpm.

•

LOW ow model,

ow requirement

below 3 lpm.

2. Alarmed Oxygen

Monitor / Analyzer

inaccurate

3. Low ow bleed

obstructed

4. Gas supply

contaminated or

heliox concentration

incorrect

5. Downstream device

causing back ow

or restricted ow

6. Supply pressure

imbalanced

1. Use auxiliary outlet &

engage bleed

2. Recalibrate alarmed

Oxygen Monitor /

Analyzer or Verify

with second alarmed

Oxygen Monitor /

Analyzer

3. Remove obstruction

4.

Check gas sources

with calibrated alarmed

Oxygen Monitor /

Analyzer to conrm

oxygen is 100% and

verify heliox tank content

5. Isolate Blender. Check

oxygen concentration at

Blender Outlets

6.

Assure

heliox

and

oxygen inlets pressures

are within 10 psi

Noowat

Blender outlets

1. Gas sources turned

“OFF”

2. Gas sources not

connected

1. Turn gas sources “ON”

2. Connect gas sources

Alarm sounding

1.

Difference between

oxygen and heliox

inlet pressures

greater than specied

1. Correct pressure

difference until heliox

and oxygen pressures

are within specication