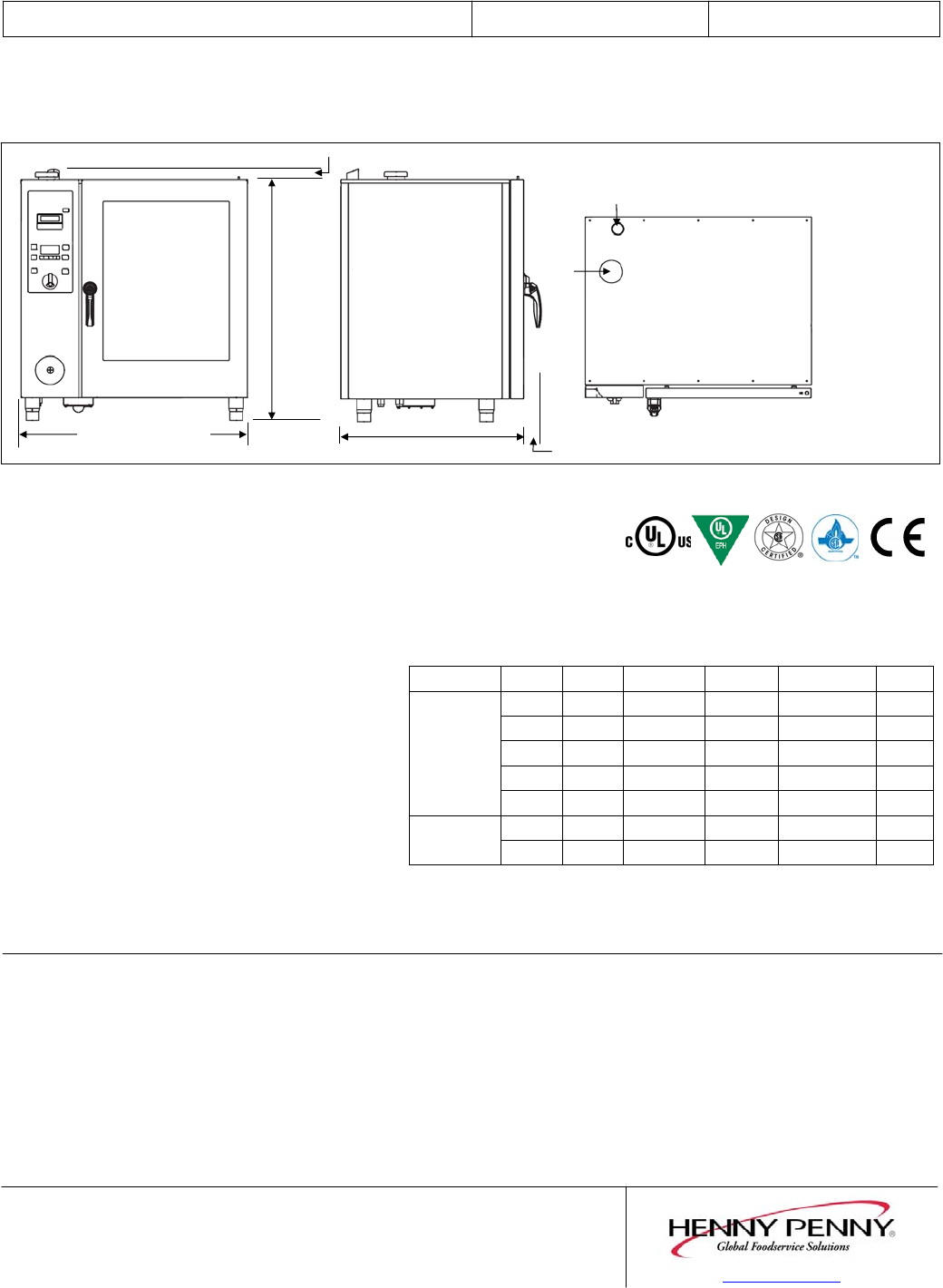

Dimensions

Height: 41 ¾ in. (1060 mm)

Width: 39 ¼ in. (997 mm) Gas +25 mm

Depth: 31 ½ in. (799 mm)

Required clearances

Left: 20 in. (500 mm) service access:

Right: 2 in. (50 mm) air flow

Back: 2 in. (50 mm) air flow,

utility connections:

Front: 28 in. (700 mm) door open

Crated dimensions

Length: 42 ½ in. (1080 mm)

Depth: 38 in. (962 mm)

Height: 50 ½ in. (1283 mm)

Volume: 47 cu. ft. (1.33 m³)

Net weight: 355 lbs. (160 kg)

Crated weight: 430 lbs. (195 kg)

Pan capacity

• 10 full-size sheet pans, 18 x 26 in. (460 x 660 mm), directly into full-size sheet pan rack or on shelves in 2/1 GN rack

• 20 full-size steam table pans, 2 ½ in. (65 mm) deep, in 2/1 GN rack only

• 6 standard 6-chicken grids, 36 chickens per load in 2/1 GN rack only

31 ½ in. (799 mm)

Add 3 in. (76 mm) for door handle

Water connections

¾ in. standard cold water connection

¾ in. soft water connection

2 in. (50 mm) drain

Power

Electric units: Connected load 32.0 kW

Gas units: Output:

89000 BTU/hr

Connection: R ¾" NPT external thread

Options: Natural Gas or LP

© 2007Henny Penny Corporation, Eaton, OH 45320 USA Revised 7/17//07

Laboratory certifications

Continuing product improvement may subject specifications to change without notice.

ClassicCombi

™

Combi Oven

Electric or gas

PROJECT QUANTITY ITEM NO

MODEL ECC-120 electric

GCC-120 gas

Bidding Specifications

• Provide Henny Penny Model ECC-120

(electric) or GCC-120 (gas) combination

oven. Models enable the selection of

convection (hot air), gentle or regular steam

or a combination of these cooking modes.

• Units shall have LED displays that provide

viewing of time, temperature and other

data.

• Units shall have manual humidification.

• Units shall have step-function with up to

3 cooking steps in sequence.

• Units shall have a condensate drip pan with

central direct drain.

• Units shall have a cabinet fan with two

rotation directions to enable autoreverse

operations.

• Units shall have seamless stainless steel

cooking chamber, a door with double-glass

window, integrated door contact switch, door

latch and pluggable door seal.

• Units shall have Advanced Steam

Technology.

™

www.hennypenny.com

•

Units shall have 572°F electric (482°F gas)

[300°C electric (250°C gas)] maximum

operating temperature using hot air

convection with accurate temperature

controls at all operating temperatures.

• Units shall accommodate up to (10) full-size

sheet pans 18 x 26 (460 x 660 mm) or

(20) steam table pans, 2 ½ in. deep.

Electrical Volts Phase Cycle/Hz Watts Amps Wire

208 3 60 27500 79.9 3+G

240 3 60 27500 69.8 3+G

400 3 50/60 27500 45.0 3NG

440 3 60 27500 37.2 3+G

Electric

units

480 3 60 27500 34.3 3+G

120 1 60 800 N/A 1NG Gas units

230 1 50 800 N/A 1NG

1 ¾ in. (44 mm) to top of stack

41 ¾ in.

(1060 mm)

A B

C

D

E

F

Utility locations

A Electrical

B Gas line

C Water connections

D Drain

E Exhaust air

F Exhaust steam

39 ¼ in. (997 mm)

Gas +25 mm