– 17 –

MAINTENANCE

WARNING: DISCONNECT ELECTRICAL POWER SUPPLY (BOTH DISHWASHER AND BOOSTER

IF APPLICABLE) AND PLACE A TAG(S) AT THE DISCONNECT SWITCH(ES) TO INDICATE THE

CIRCUIT(S) ARE BEING WORKED ON BEFORE BEGINNING ANY MAINTENANCE PROCEDURE.

WASH ARMS

Upper and lower wash and rinse arms (Figs. 11, 12) should turn freely and continue turning for a few

seconds after being whirled by hand. To check, DISCONNECT ELECTRICAL POWER SUPPLY

(BOTH DISHWASHER AND BOOSTER IF APPLICABLE), rotate arms, and remove any obstructions

causing improper operation.

If the slanted strainer or strainer bucket is not properly in place, obstructions (such as food particles

or bones) may clog the wash arm nozzles. The wash arms are easily removed for cleaning.

Removing Wash / Rinse Arms — AM14 / AM14C

To remove the lower wash arm, first lift off the rinse arm; then, using a dowel (or end of punch),

unscrew the rinse arm bearing pin (Fig. 11) and lift off the lower wash arm. It is not necessary

to remove the spacer located on the lower wash arm shaft.

The upper wash and rinse arms are removed by unscrewing the hand knob (Fig. 12) and lowering

both arms together. Be careful not to drop these arms.

MOTOR(S)

The wash pump motor and the blower motor used on gas heat machines are equipped with

permanently lubricated bearings and require no lubrication maintenance.

GAS FLUE (Machines equipped for gas heat only.)

When cool, check the flue opening every three months for obstructions.

TROUBLESHOOTING

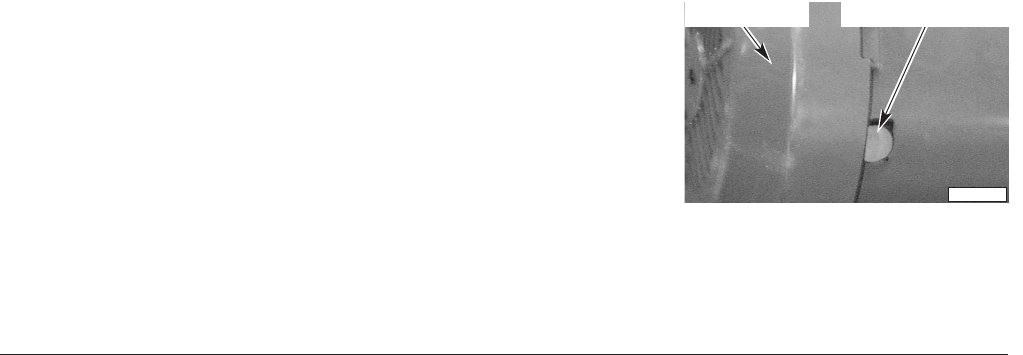

Manual Reset Button on Pump Motors (When Equipped)

In case the pump becomes overheated, the thermal overload will

cause the motor to not operate. Motors equipped with Automatic

Reset will become operational after they cool down. Some motors

are equipped with a gray manual reset button on the bottom of the

motor near the endbell opposite of the motor junction box (Fig. 13).

To restart motors equipped with reset button after the motor has

cooled, press the gray manual reset button.

Fig. 13

PL-41450-1

MOTOR ENDBELL

MOTOR RESET BUTTON