– 13 –

VENTING REQUIREMENTS

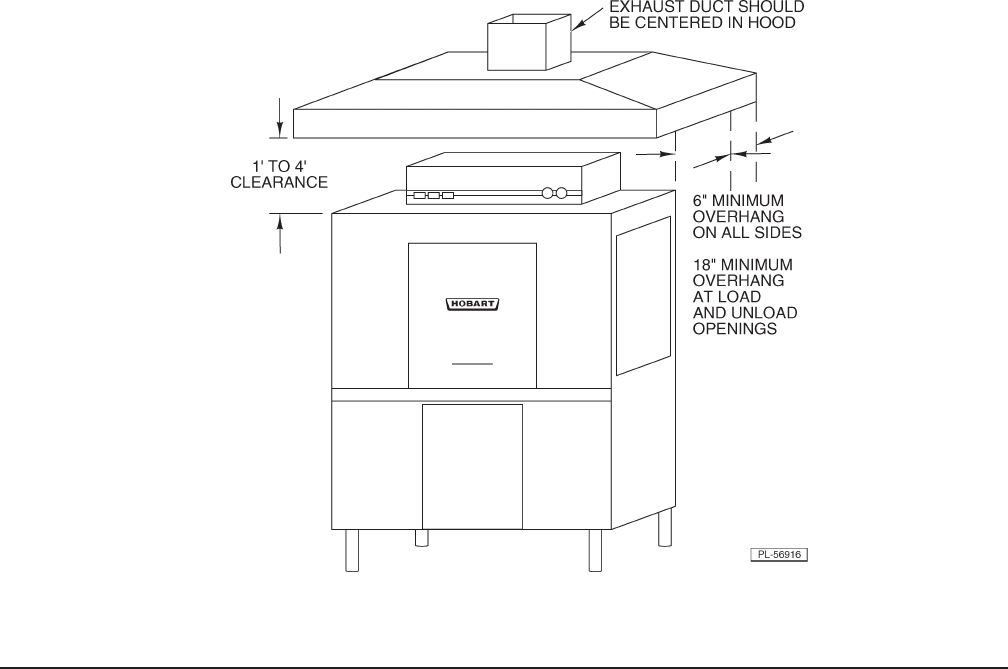

Type II Canopy Hood

Most commercial dishwashers must be provided with external venting per local codes. The exception

is electric or steam heat machines operating in the chemical or low temperature sanitizing mode where

the existing room ventilation will compensate for the vapors produced. The local authority has final

jurisdiction over this matter.

Venting can be provided by either the pant-leg duct connections (Fig. 8) or by a vent hood over the

whole machine (Fig. 6).

The Hobart C-Line dishwasher equipped for gas tank heat is not provided with a flue collar and is not

intended to have the flue directly connected to a ventilation system. However, the products of

combustion must be vented to the outside air. A vent hood over the entire dishwasher (Fig. 6) can be

employed to vent both the moist air from the dishwashing chamber and the flue gases from the gas

heater. The volume of flue exhaust required for venting moist air and flue gases using a single vent

hood over the entire dishwasher must be calculated using the formula in the

Perimeter Calculation

Formula

on page 16.

Type I or Type II canopy hoods are recommended. A factory-built commercial exhaust hood may be

listed as conforming to Underwriters Laboratory's standard 710 titled,

Exhaust Hoods for Commercial

Cooking Equipment

. Hoods must be installed according to the manufacturer's instructions. Makeup air

must be provided so that the exhaust flow rate results in a positive building pressure in the room where

the unit is located (more outside air than exhaust air). Factory-built hoods not tested to UL standard

710 and custom built hoods must comply with the following specifications: Stainless steel 0.037" [No.

20 Gage] minimum thickness or copper sheet weighing at least 24 ounces per square foot; the hood

must be secured in place by noncombustible supports and must meet the RATE OF EXHAUST FLOW

CALCULATIONS.

Fig. 6

TYPE II

CANOPY HOOD