701 S Ridge Avenue, Troy, OH 45374

1-888-4HOBART • www.hobartcorp.com

Page 2 of 2 F-39964 – HO851G Revolving Tray Oven - Gas

As continued product improvement is a policy of Hobart, specications are subject to change without notice.

HO851G REVOLVING

TRAY OVEN - GAS

F-39964 (REV. 08/08) LITHO IN U.S.A. (H-01)

SPECIFICATIONS:

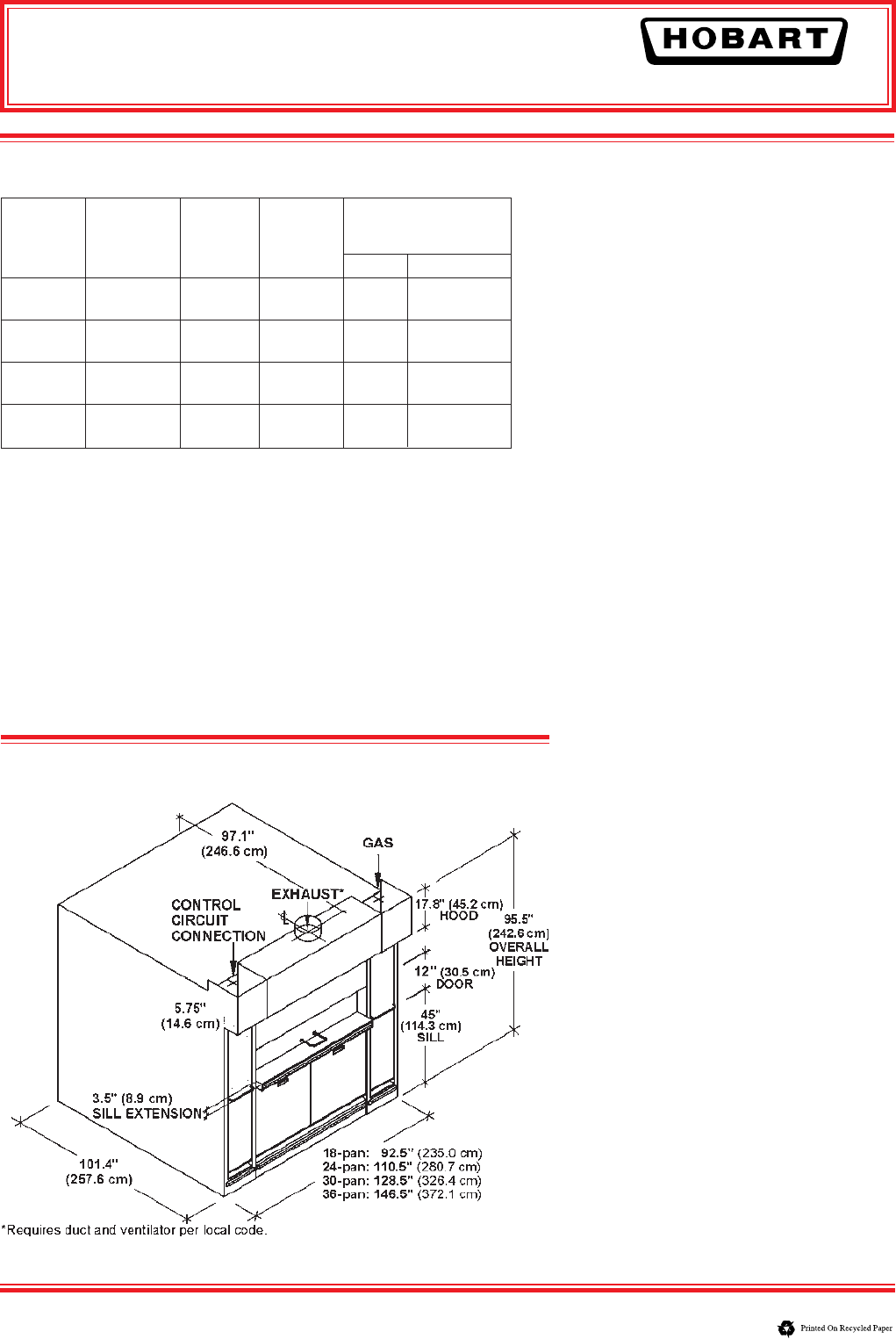

DETAILS AND DIMENSIONS

Gas – 1" NPT pipe size; Standard – Natural Gas @

5"-14" w.c.; Optional – Propane Gas @ 13"-14" w.c.

Must not exceed 14" w.c.

Electrical – 120V/60Hz/1 PH. Oven control: 12.0

amps.

Oven provided relay with 120V output for fan opera-

tion, 4.0 amp max

1

⁄6 H.P.

Hood – Suitable for Type I or Type II applications.

See table for duct size and fan cfm requirement by

model. 0.6"w.c. static pressure drop at hood.

NATURAL

GAS PROPANE

WGT MAX. GAS

VENTING

(LBS) CAPACITY BTU/HR BTU/HR CFM DUCT. DIA.

5121 8"

(2323 kg)

18-PAN

250,000 200,000

700

(20.3 cm)

5812 10"

(2636 kg)

24-PAN

300,000 250,000

900

(25.4 cm)

6429 10"

(2916 kg)

30-PAN

300,000 250,000

1200

(25.4 cm)

7122 10"

(3231 kg)

36-PAN

350,000 300,000

1400

(25.4 cm)

Customer to supply duct and roof mounted

fan per local code. If accepted by local

building ofcials, suitable for connection

to Type B pipe except when products of

baking are grease laden. Airow proving

switch is factory installed and integrated

with burner system operation. Oven

provided relay with 4.0 amp max

1

/6 H.P.

@ 120V output for fan control.

Type I: For grease laden vapors, products

of combustion. (See NFPA 96 and consult

local building ofcials.)

Type II: For heat, steam, odors and products of

combustion.

NOTES

1. Level oor required. Floor should be level within

1

/8" per foot for proper installation. Slope should

not exceed

3

/4" in all directions under the unit.

2. The purchaser is responsible for proper installation

in order to validate the warranty.

A factory technician or factory

authorized installation technician

must supervise and approve any

installation.

3. Purchaser is responsible for all

installation costs and for providing:

labor to unload oven upon arrival;

installation mechanics; all local

service connections - electricity,

vents, gas per local code; and

disposal of packaging material.

4. Minimum clearances to combustible

construction: 1 inch from sides and

back, 3 inches from top. Caution:

To reduce the risk of re, the oven

is to be mounted on oors of

non-combustible construction

with non-combustible ooring

and surface nish and with no

combustible material against the

underside thereof.

5. Do not route utilities (wiring,

plumbing, etc.) in or under the non-

combustible oor beneath the oven.