SPYDER® LON PROGRAMMABLE, VAV/UNITARY CONTROLLERS

7 62-0287—03

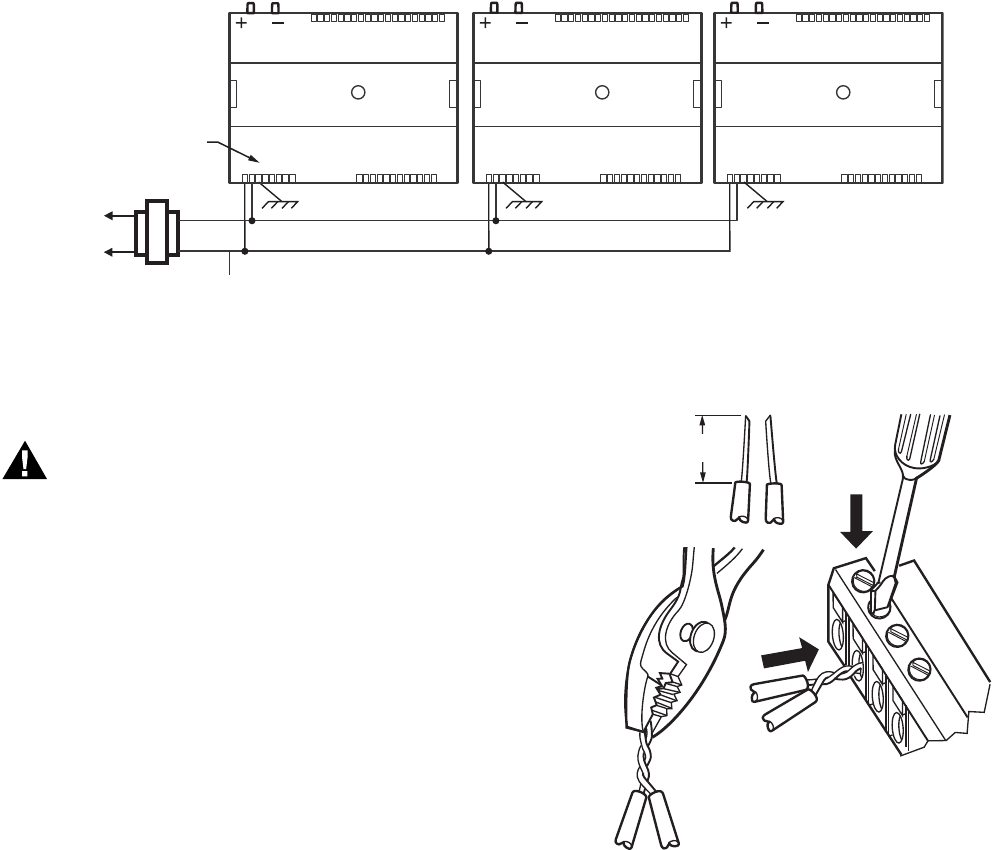

Fig. 12. Power wiring details for two or more controllers per transformer.

Wiring Method

WARNING

Electrical Shock Hazard.

Can cause severe injury, death or property

damage.

Disconnect power supply before beginning wiring, or

making wiring connections, to prevent electrical shock

or equipment damage.

NOTE: When attaching two or more wires to the same termi-

nal, other than 14 AWG (2.0 sq mm), be sure to twist

them together. Deviation from this rule can result in

improper electrical contact (see Fig. 13).

Each terminal can accommodate the following gauges of wire:

— Single wire: from 22 AWG to 14 AWG solid or stranded

— Multiple wires: up to two 18 AWG stranded, with 1/4 watt

wire-wound resistor

Prepare wiring for the terminal blocks, as follows:

1. Strip 1/2 in. (13 mm) insulation from the conductor.

2. Cut a single wire to 3/16 in. (5 mm). Insert the wire in

the required terminal location and tighten the screw.

3. If two or more wires are being inserted into one terminal

location, twist the wires together a minimum of three

turns before inserting them (see Fig. 13).

4. Cut the twisted end of the wires to 3/16 in. (5 mm)

before inserting them into the terminal and tightening

the screw.

5. Pull on each wire in all terminals to check for good

mechanical connection.

Fig. 13. Attaching two or more wires at terminal blocks.

Controller Replacement (PVL0000AS,

PVL4022AS, and PVL6436AS)

For PVL0000AS, PVL4022AS, and PVL6436AS controllers,

which are hard-wired to an actuator, perform the following

actions to replace the complete assembly (controller and

actuator):

1. Remove all power from the controller.

2. Remove the two air flow pickup connections from the

pressure sensor.

3. Remove the terminal blocks.

4. Remove the old controller and actuator assembly from

its mounting.

• Loosen the two bolts on the actuator clamp to

release the actuator from the shaft.

• Remove the controller’s mounting screws.

• Gently pull the controller and actuator assembly

straight out, until the assembly is clear of the

actuator shaft.

M23559A

120/240

VAC

TRANSFORMER

OUTPUT

DEVICE

POWER

ΔP

1

2

3 4 5 6

7 8

1 0 9 2 3 4 5 6 7 8 0 9

1 1 1 1 1 1 1 1 1 2 1

1

2

3 4

5

6

7 8

0

9

2

2 2

2 2

2

2

2 2

3

3

1

2

3 4

5

6

7 8

0

9

3

3

3

3 3

3 3

3 4

COM

24 VAC

ΔP

1

2

3 4 5 6

7 8

1 0 9 2 3 4 5 6 7 8 0 9

1 1 1 1 1 1 1 1 1 2 1

1

2

3 4

5

6

7 8

0

9

2

2 2

2 2

2

2

2 2

3

3

1

2

3 4

5

6

7 8

0

9

3

3

3

3 3

3 3

3 4

EARTH

GROUND (TERMINAL 3)

ΔP

1

2

3 4 5 6

7 8

1 0 9 2 3 4 5 6 7 8 0 9

1 1 1 1 1 1 1 1 1 2 1

1

2

3 4

5

6

7 8

0

9

2

2 2

2 2

2

2

2 2

3

3

1

2

3 4

5

6

7 8

0

9

3

3

3

3 3

3 3

3 4

EARTH

GROUND (TERMINAL 3)

EARTH

GROUND (TERMINAL 3)

CONNECT POWER TO

TERMINALS 1 AND 2

1/2

(13)

STRIP 1/2 IN. (13 MM)

FROM WIRES TO

BE ATTACHED AT

ONE TERMINAL.

1.

2.

TWIST WIRES

TOGETHER WITH

PLIERS (A MINIMUM

OF THREE TURNS).

3.CUT TWISTED END OF WIRES TO 3/16 IN. (5 MM)

BEFORE INSERTING INTO TERMINAL AND

TIGHTENING SCREW. THEN PULL ON EACH

WIRE IN ALL TERMINALS TO CHECK FOR

GOOD MECHANICAL CONNECTION.

M17207