3

G. Connection to an R-404A Parallel Rack System

WARNING

1. Installation must be performed by properly trained and EPA-certied service

personnel.

. Failure to install the equipment within these guidelines may adversely affect

safety, performance, component life, and warranty coverage.

3. The icemaker, line set, and rack system must contain the same type of

refrigerant. Mixing of refrigerants will result in improper operation and

possible damage to the refrigeration system.

• The rack system must be sized to provide a maximum load of 5,700 BTU/h at 90°F (3°C)

ambient temperature and 70°F (1°C) water temperature.

• Install a p-trap in the suction line if required by the rack system's instructions.

• The evaporator pressure regulator (EPR) valve is factory adjusted to sustain a suction

pressure of 31 PSIG for a -°F (-19°C) evaporator temperature. Adjust only if necessary.

• The icemaker is shipped with a holding charge of 3.5 oz. of R-404A.

• Charging port-equipped Parker quick connect couplings are needed to connect the line

set to the icemaker.

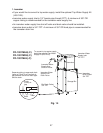

1. Line Set Installation

1) Route a 3/8" OD copper tube suction line and a 1/4" OD copper tube liquid line between

the icemaker and the rack system. Leave a service loop behind the icemaker to allow

the icemaker to be pulled out for service. See Fig. 11.

CAUTION

Do not coil extra line set. Fabricate the line set to the proper length.

) Insulate the copper tubes separately.

3) Braze the charging port-equipped Parker quick connect couplings to the icemaker end

of the copper tubes. Do not connect the charging port-equipped Parker quick connect

couplings to the icemaker at this time.

4) When using couplings to connect the line set to the rack system, braze them to the

rack system end of the copper tubes. Otherwise, braze the line set directly to the rack

system. Do not open the rack system service valves at this time.

5) Use an electronic leak detector or soap bubbles to check for leaks. Add a trace of

refrigerant to the line set copper tubes (if using an electronic leak detector), and then

raise the pressure using nitrogen gas (140 PSIG). WARNING! DO NOT use R-404A

as a mixture with pressurized air for leak testing.

6) Evacuate the line set copper tubes through the charging ports on the Parker quick

connect couplings and charge with R-404A refrigerant vapor to a pressure of 15 to

30 PSIG.