EF and EMF Series Start-Up Procedure

Page 11

●Check bin control for proper operation

The bin control is used to shut the machine off when the bin fills with ice. The bin control must be checked upon

installation or initial start-up and when performing maintenance. Adjustments are not covered under warranty.

With the machine running and making ice, hold ice against the brass thermal well that houses the bin control capillary

tube. The brass thermal well is located on the inside of the down chute on the EMF models and in the storage bin on

the EF models. The machine should shut off in approximately 2 minutes. Remove the ice from the thermal well and

the machine should come back on within 2 minutes. The bin control adjusting screw can be accessed through a hole

in the control box. Note: On some models there will be a compressor delay of 2 to 4 minutes after turning the machine

on.

If ice is touching the bin control thermal well for more

than 3 minutes and the machine has not shut off, turn

the adjusting screw counter-clockwise approximately

1/8 turn and recheck.

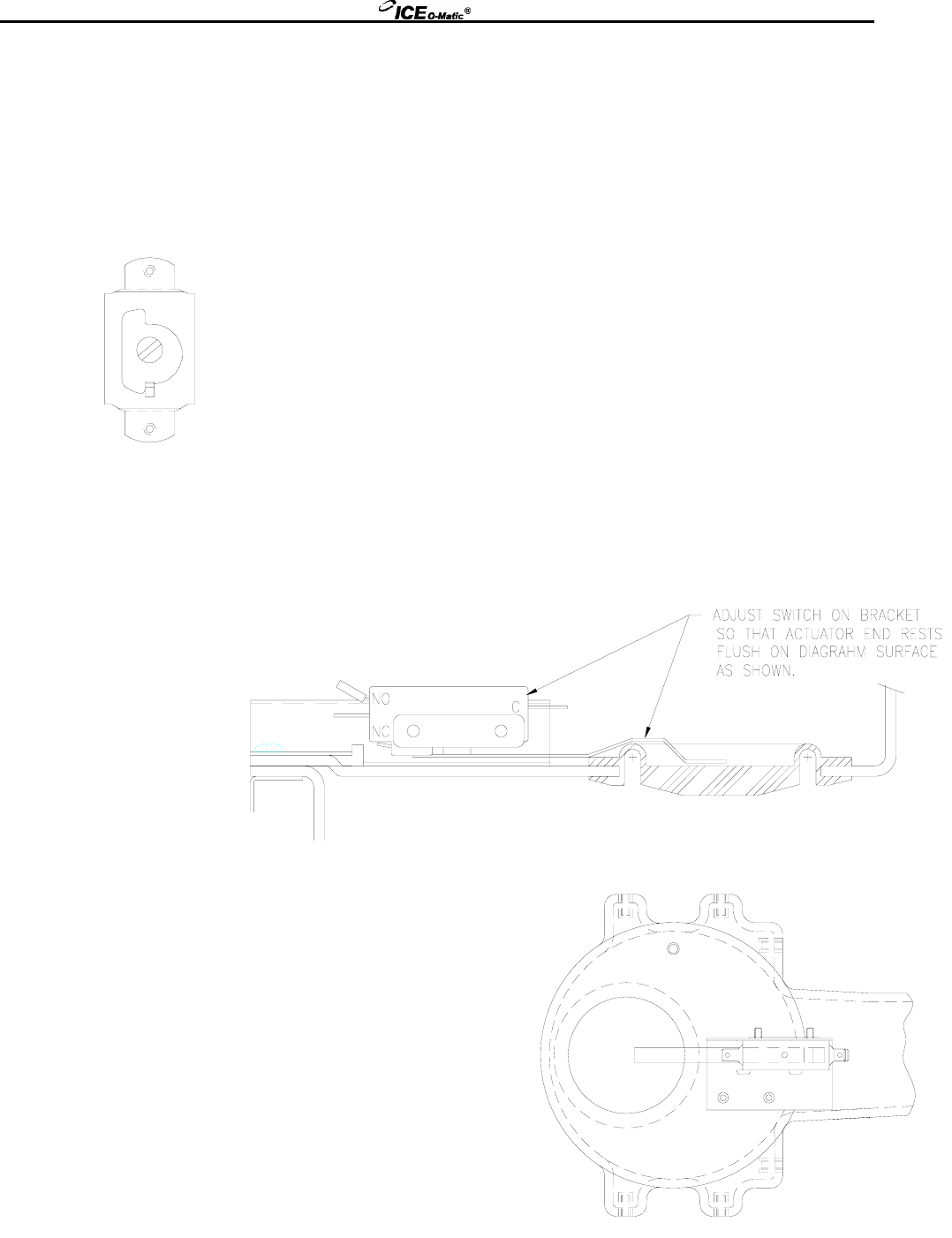

●Check secondary bin control for proper operation

EF Series Flakers: With the machine off, reach inside the bin and push up on the white diaphragm located at the top of

the bin. The switch contacts should change before the diaphragm is lifted ½ inch. Contacts should change again

when the diaphragm is

released. To adjust switch,

remove cabinet top and

move switch to proper

position.

EMF Series Flakers: With the machine off, lift up slightly on the

white diaphragm located on top of the down chute. The switch

contacts should change before the actuator is lifted more than ½

inch. Contacts should change again when the diaphragm is

released. To adjust switch, remove cabinet top and move

switch to proper position.

●Check for water leaks and excessive noise.