Flake Ice Machines Drive System

Page E7

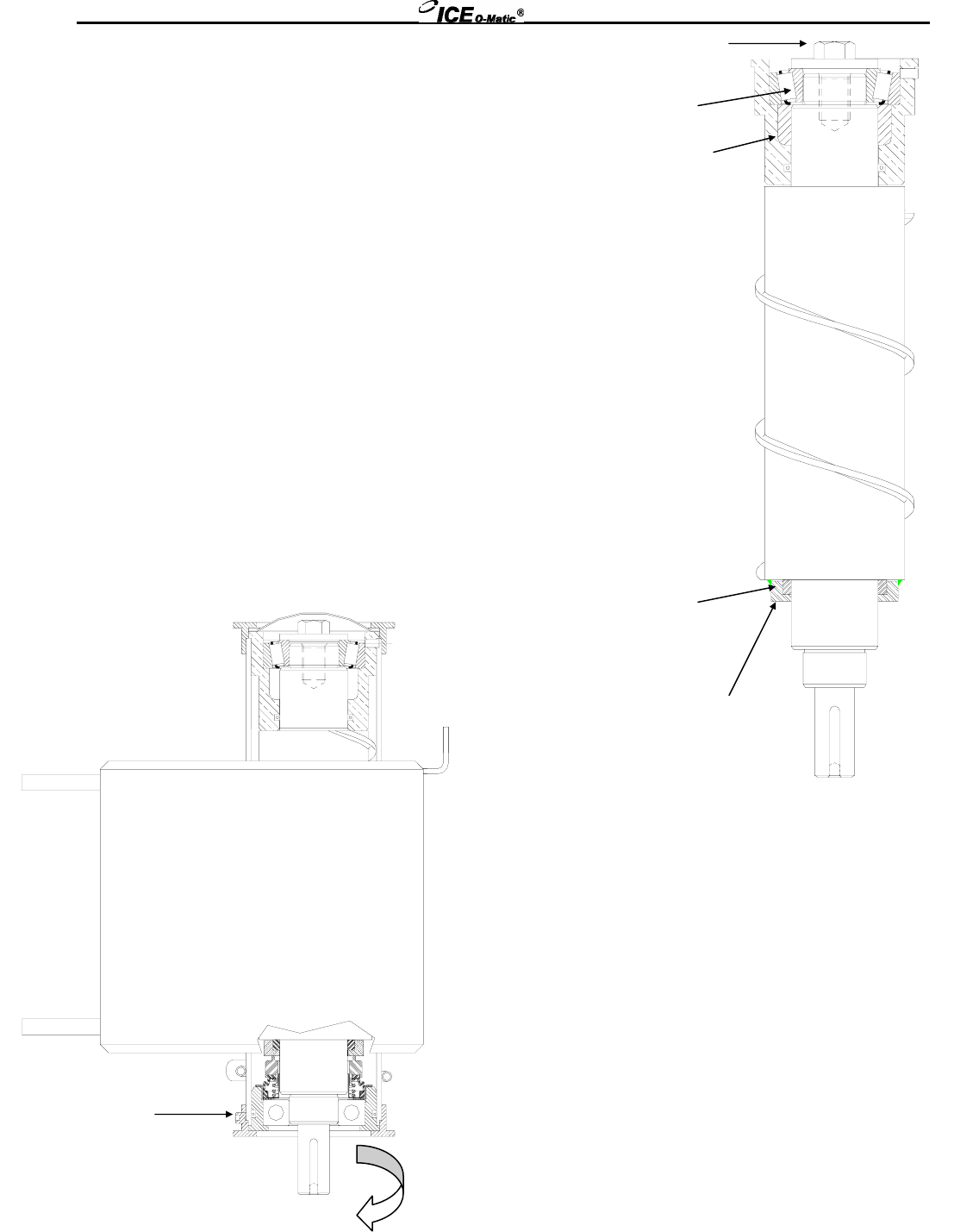

Seal Face Installation

Lightly lubricate the rubber portion of the seal face and

apply a small amount of silicone sealant to the metal

part of the seal face (rubber side) that seats against

the auger. Install the seal face on the auger.

Caution: Do not scratch or damage the seal face.

Evaporator Reassembly

Lubricate the upper O-Ring with food grade white grease

and attach the upper housing to the auger. Pack the tapered

roller bearing with Chevron Oil FM Grease EP NLGI 0 or

equivalent. Fill the cavity below the bearing with

grease. Install the bearing over the bearing journal, install

the washer and bolt, tighten to 40 ft/lbs.

Lightly lubricate the O-Ring on the lower housing and install the

complete lower housing into the evaporator by applying even

pressure upward. It may be necessary to tap the housing with a

rubber mallet or with a hammer and hard wooden block. Install

and tighten the lower evaporator nut. Install and

tighten the lower nut setscrews.

Carefully install the auger and upper housing

assembly into the evaporator barrel, taking care

not to scrape the evaporator walls. Push

downward on the housing until the bearing

housing is seated against the evaporator barrel.

A rubber mallet may be needed to tap the

housing into place. Install the grease cap and

tighten the upper evaporator nut.

Reverse the first 6 steps in the Evaporator

Disassembly Section.

Fill cavity with grease

Tor

q

ue bolt to 40 ft/lbs.

Apply silicone sealant to the

rubber side of the seal; do not

apply silicone to the flat portion of

the seal

Torque setscrews to

55 inch pounds

Carefully install the seal face,

as shown, do not damage the

flat portion of the seal

Auger should turn freely by hand

Pack bearing with

grease prior to

installation