2

92266

It is very important that the air intake and discharge sides of the chiller are not obstructed by other free standing

objects. A minimum of two feet of space on all four sides of the chiller will be sufficient to prevent air flow ob-

structions.

It is also important to direct any hot air discharge from other equipment away from the air intake side of the chill-

er. Condenser air entering the “CH” unit should be below 100_ F (38_ C) .Condenser air temperatures above

100_ F (38_ C) can cause the high pressure safety control to shut down the unit.

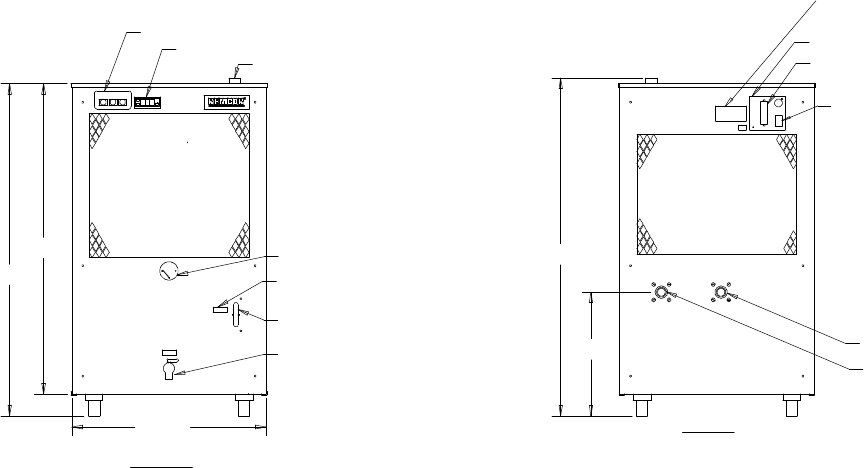

Electrical Connections

All wiring must conform to the National Electric Code and any applicable local codes.

The “CH” unit must be PERMANENTLY wired by means of electrical conduit to a properly fused disconnect of

proper amperage OR wired to a properly rated power cord and plugged into an outlet with the appropriate dis-

connect and amperage rating. The electrical junction box includes a four terminal strip for power supply connec-

tions. The DATA PLATE located beside the junction box indicates the phase, voltage and amperage of the

chiller.

Process Connections

Follow standard plumbing practices and local codes in making liquid connections. The Chiller inlet and outlet

connections are 3/4”--inch FPT couplings. It is recommended that 3/4--inch I.D. or larger flexible hose and tube

fittings be used as process connections. Lines should be routed with as few bends as possible. Prevent lines

from running near radiators, hot water pipes, etc. Any lengths of tubing that are exposed to high ambient tem-

peratures should be insulated to prevent condensation and/or significant liquid heat gain.

Once the system has been properly plumbed, it is important that the circulation system be filled with liquid. The

reservoir can be filled by removing the fill port cap located on top of the Chiller. After ensuring that the drain is

closed, fill the reservoir via the fill port with pure liquid until the liquid level sight glass on the front of the unit indi-

cates ”FULL”. The fill port cap should then be replaced prior to operation.

INTERLOCK STRIP

(IF APPLICABLE)

JUNCTION BOX

DATA PLATE/SERIAL NO.

OUTLET

TERMINAL STRIP

REAR

INLET

14.000

38.224

DRAIN

37.638

PRESSURE GAUGE

”FULL”

FRONT

35.138

21.963

RESERVOIR LEVEL INDICATOR

FILL PORT

TEMPERATURE CONTROLLER

CONTROL PANEL

FIGURE 1. “CH” SERIES CHILLERS