78

166240004

12/1/94

Rev 3/4/96

REMOTE SYSTEM EVACUATION/RE-CHARGE

All field repairs to the sealed system must start with a total discharge of the system following the requirements

of the Clean Air Act of July, 1992.

Proper evacuation of the total remote system will require a three (3) point hook-up of your manifold and hose

set, (see drawing):

Point #1 - Cuber receiver outlet valve

Point #2 - Cuber high side service valve

Point #3 - Cuber low side service valve

Evacuation:

1. With cuber power supply turned “OFF” disconnect and insulate all 3 compressor leads at the compressor.

Turn power supply on, place power switch in the “on” position. This will energize (open) the Liquid Line so-

lenoid allowing evacuation of the Liquid Line between the solenoid and the expansion valve(s).

2. Evacuate system to 200/250 microns or less. At this point, there should be a holding test of five(5) minutes.

You may expect a slight loss of vacuum as normal. A rapid rise to normal atmospheric pressure indicates

moisture still present in the system. On a “wet” system, it will prove beneficial to use heat lamps to warm

the compressor dome and evaporator surface during evacuation.

3. Turn cuber power switch OFF. Reconnect compressor leads.

4. *After proper evacuation hold test has been performed, the refrigerant charge should be “dumped” into the

receiver until the pressure equalizes, stopping the flow. Do not try to throttle the refrigerant flow. Doing so

will allow system pressure to balance too soon. The high-side service valve should be closed and the bal-

ance of the charge fed slowly through the suction side service valve with the compressor operational. Con-

trol the feed rate at no faster than four (4) ounces [113.g] per minute to ensure the compressor oil does not

become too saturated with refrigerant resulting in a loss of compressor lubrication.

5. All refrigerant re-charging must be weighed into the system, utilizing an electronic charging scale. DO NOT

attempt to recharge the system by sight glass, system pressure, amperage, frost line or sweat patterns.

6. Always leak check entire system after recharge.

CAUTION: Before programming the electronic scales to “dump” the charge, de-energize

the liquid line solenoid, close the shut-off valve on vacuum pump and low side of the

manifold set.

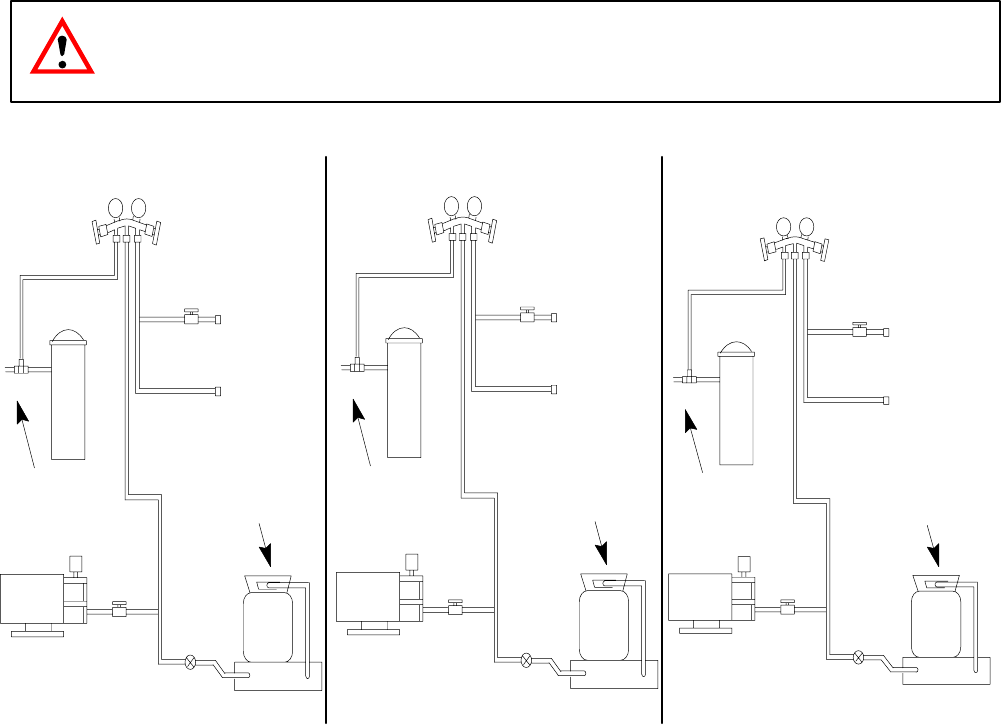

EVACUATION

MANIFOLD SET

OPEN

RECEIVER

OPEN

RECEIVER

OUTLET

VA LV E

OPEN

VACUUM

PUMP

ELECTRONIC

SCALE

CHARGING

CYLINDER

CLOSED

CLOSED

LOW

SIDE

SERVICE

VA LV E

HIGH SIDE

SERVICE

VA LV E

OPEN

OPEN

1ST STAGE CHARGING

MANIFOLD SET

OPEN

RECEIVER

OPEN

RECEIVER

OUTLET

VA LV E

OPEN

VACUUM

PUMP

ELECTRONIC

SCALE

CHARGING

CYLINDER

CLOSED

LOW

SIDE

SERVICE

VA LV E

HIGH SIDE

SERVICE

VA LV E

2ND STAGE CHARGING

COMPRESSOR OPERATING

MANIFOLD SET

RECEIVER

RECEIVER

OUTLET

VA LV E

OPEN

VACUUM

PUMP

ELECTRONIC

SCALE

CHARGING

CYLINDER

CLOSED

CLOSED

LOW

SIDE

SERVICE

VA LV E

HIGH SIDE

SERVICE

VA LV E

OPEN

OPEN

CLOSED

CLOSED

OPEN

CLOSED

CLOSED