3

Installation instructions

All instruction on the following pages must be carried out by

a competent person (corgi registered) in compliance with

gas safety (installation and use) regulation 1984.

Important: disconnect the cooker from the electrycity

and gas supply when any adjustment, etc.

Positioning

Important: this unit may be installed and used only in

permanently ventilated rooms according to the British

Standards Codes Of Practice: B.S. 6172/B.S. 5440, Par. 2

and B.S. 6891 Current Editions. The following requirements

must be observed:

a) The cooker should not be installed in a bed sitting room

with a volume of less than 20m

3

. If it is installed in a room

of volume less than 5m

3

an air vent of effective area of

110cm

2

is required, if it is installed in a room of volume

between 5m

3

and 10m

3

a supplementary airvent area of

50cm

2

is required, while if the volume exceeds 11m

3

no

airvent is required. However, if the room has a door or a

window vhich opens directly to the outside no air vent is

required even when the volume is between 5m

3

and 11m

3

.

b) During prolonged use of the appliance you may consider

it necessary to open a window to the outside to improve

ventilation.

c) If there are other fuel burning appliances in the same

room, B.S.5440 Part 2 Current Edition, should, be

consulted to determine the requisite air vent requirements.

Installation of the cooker

The cooker is prepared with protection degree against

excessive heating of type X, the appliance can therefore be

installed next to cabinets, provided the height does not exceed

that of the hob. If the cooker is placed touching walls or sides

of neighbouring cabinets, these must be capable of

withstanding a temperature rise of 60°C above room tempe-

rature. Levelling feet supplied with the cooker, can be fitted

to the cooker to accomodate uneven floors. See fitting

instruction on feet packing. For a correct installation of the

cooker the following precautions must be followed:

a) The cooker may be located in a kitchen, a kitonen/diner

or bed sitting room, but not in a bathroom or shower room.

b) The furniture units next to the cooker, that is higher than

the working boards, must be placed at least 110 mm from

the edge of the board. Curtains must not be fitted

immediately behind the cooker or within 110 mm. of the

sides of the cooker.

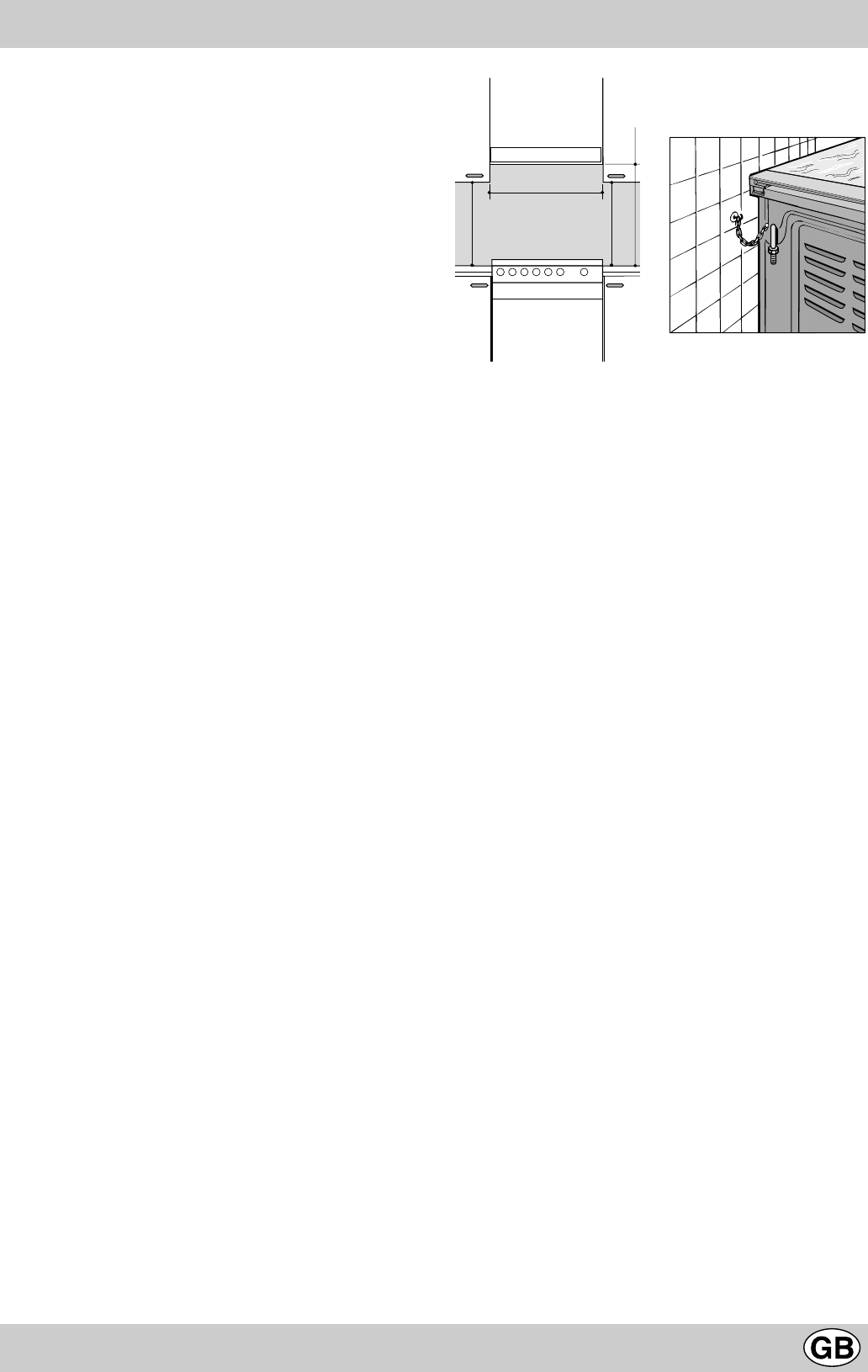

c) The hoods must be installed according to the

requirements in the hood handbook.

d) Wall cabinets may be fitted in line with the sides of the

base units, providing that the lower edge of the wall cabinet

is a minimum of 420 mm. above the worktop. The

minimum distance combustible material kitchen units can

be fitted directly above the worktop is 700 mm. (see Fig.

A)

e) The wall in contact with the back of the cooker must be of

flameproof material.

f) The cooker is fitted with the a safety chain that must be

attached to a hook, secured to the wall behind the

appliance (see Fig. B).

HOOD

420

Min.

min.

650

mm. with hood

min.

700

mm. without hood

mm.

600

Min. mm.

420

Min. mm.

Fig. A Fig. B

Connecting the gas

The cooker should be connected to the gas-suply by a corgi

registered installer. During installation of this product it is

essential to fit an approved gas tap to isolate the supply from

the appliance for the convenience of any subsequent removal

or servicing. Connection of the appliance to the gas mains

or liquid gas must be carried out according to the prescribed

regulation in force, and only after it is ascertained that it is

adaptable to the type of gas to be used. If not, follow the

instructions indicated in the paragraph headed “Adaptation

to different gas types”. In the case of connection to liquid

gas, by tank, use pressure regulators that conform to the

regulation in force. The gas supply must be connected to the

right of the appliance. Be sure that the hose does not pass

through the rear of the cooker touching hot parts.

Important: make sure the supply pressure conforms with

the values shown in the table entitled “Caracteristics of the

burners and nozzles”.

When the cooker is installed between cabinets (recessed),

the gas connection must be effected by an approved flexible

hose with bayonet fitting (BS 669 Current Edition). The gas

inlet for the cookers is a threaded G 1/2 gas female fitting.

Connecting the gas supply

To make the connection, a flexible hose should be used

corresponding to the current gas regulations which are:

· the hose must never be at any point in its lenght in contact

with the “hot” parts of the cooker;

· the hose must never be longer than 1.5 metre;

· the hose must not be subject to any tension or torsional

stress and it must not have any excessively narrow curves

or bottlenecks;

· the hose must be easy to inspect along its entire lenght

to check its condition;

· the hose must always be in good condition, never attempt

to repair.

Important: the installation must comply with gas safety

(installation and use) regulations 1984. In all cases for the

above, by low, a qualified, corgi approved engineer must be

called for installation.