6

JP-24BPNSU Technical Manual

7610-002-38-50 Rev. D (11/11/2005)

ELECTRICAL POWER CONNECTION: Electrical and grounding connections must comply with the applicable portions of the

National Electrical Code ANSI/NFPA 70 (latest edition) and/or other electrical codes.

Disconnect electrical power supply and place a tag at the disconnect switch to indicate that you are working on the circuit.

The dishmachine data plate is located on the right side and to the front of the machine. Refer to the data plate for machine

operating requirements, machine voltage, total amperage load and serial number.

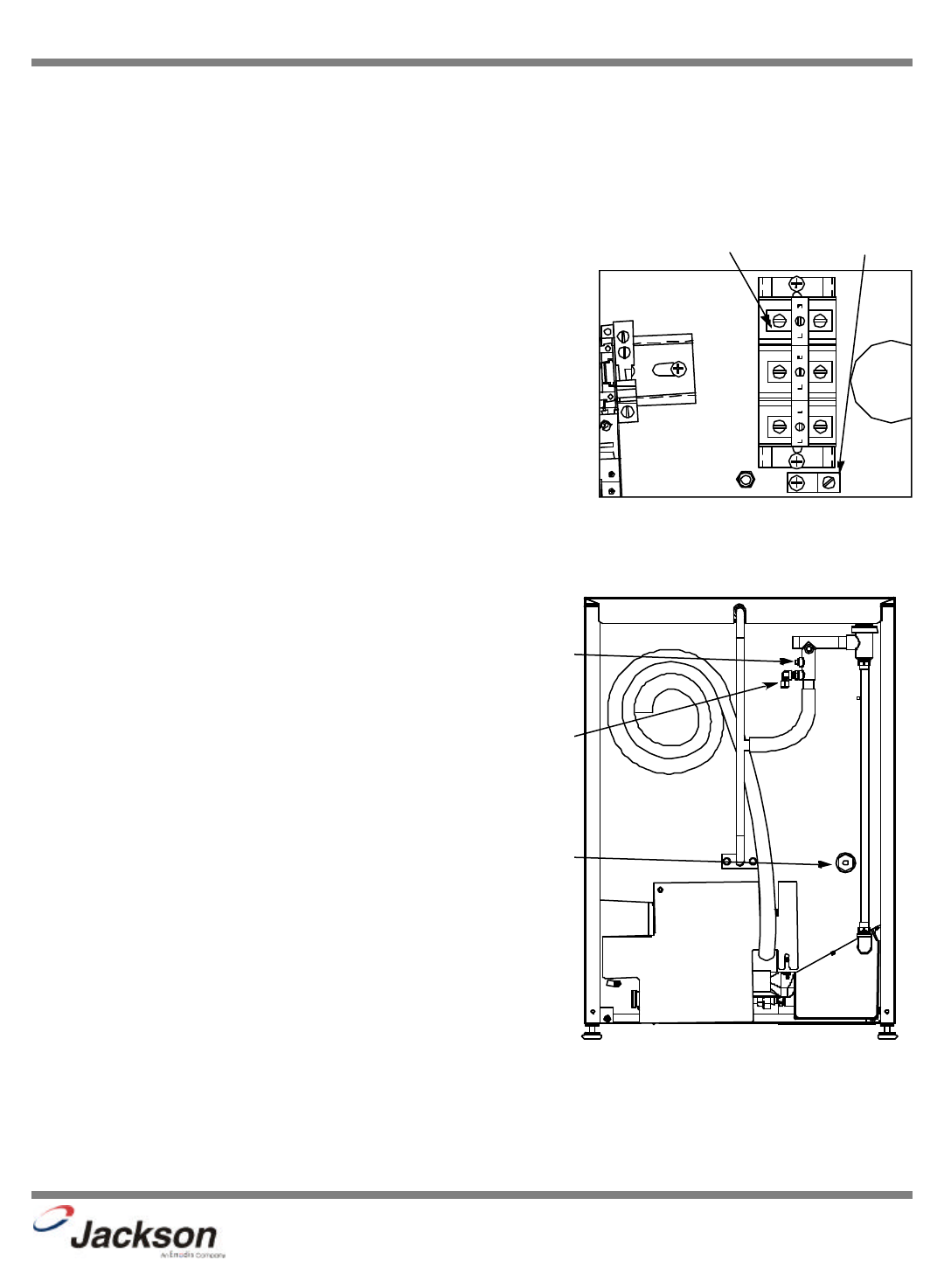

To install the incoming power lines, remove the kick panel. This will require tak-

ing a phillips head screwdriver and removing the four(4) screws on the front

cover of the kick plate. Install 3/4” conduit into the pre-punched holes in the

back of the control box. Route power wires and connect to power block and

grounding lug. Install the service wires (L1, L2 and L3) to the appropriate ter-

minals as they are marked on the terminal block. Install the grounding wire into

the lug provided. Tighten the connections and perform the “pull test”. The tight-

ened wires should remain in place after giving the wires a moderate pull to see

if they will come loose.

It is recommended that “DE-OX” or another similar anti-oxidation agent be

used on all power connections.

VOLTAGE CHECK: Ensure that the power switch is in the

OFF position and apply power to the dishmachine. Check

the incoming power at the terminal block and ensure it cor-

responds to the voltage listed on the data plate. If not, con-

tact a qualified service agency to examine the problem. Do

not run the dishmachine if the voltage is too high or too

low. Shut off the service breaker and mark it as being for

the dishmachine. Advise all proper personnel of any prob-

lems and of the location of the service breaker. Replace

the control box cover and tighten down the screws.

CHEMICAL CONNECTIONS: All chemical hookup loca-

tions are located on the back of the dishmachine. Please

refer to the drawing at the right for the correct connection

point.

This equipment is not recommend for use with deion-

ized water or other aggressive fluids. Use of deion-

ized water or other aggressive fluids will result in cor-

rosion and failure of materials and components. Use

of deionized water or other aggressive fluids will void

the manufacturer's warranty.

SECTION 2: INSTALLATION/OPERATION INSTRUCTIONS

ELECTRICAL INSTALLATION INSTRUCTIONS

Control Box Electrical Connection

Ground LugTerminal Block

Back of Unit Showing Chemical Connection Points

Rinse Aid Fitting

Brass Plug

Detergent Fitting